Elevator cabin guide rail bracket for expresselevator

A technology for elevator cars and high-speed elevators, applied in elevators, transportation and packaging, etc., can solve problems such as limited installation and adjustment range, unsuitable rigidity, tensile strength, and inconvenient installation, so as to ensure good cooperation, improve stability, Good tensile strength and stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

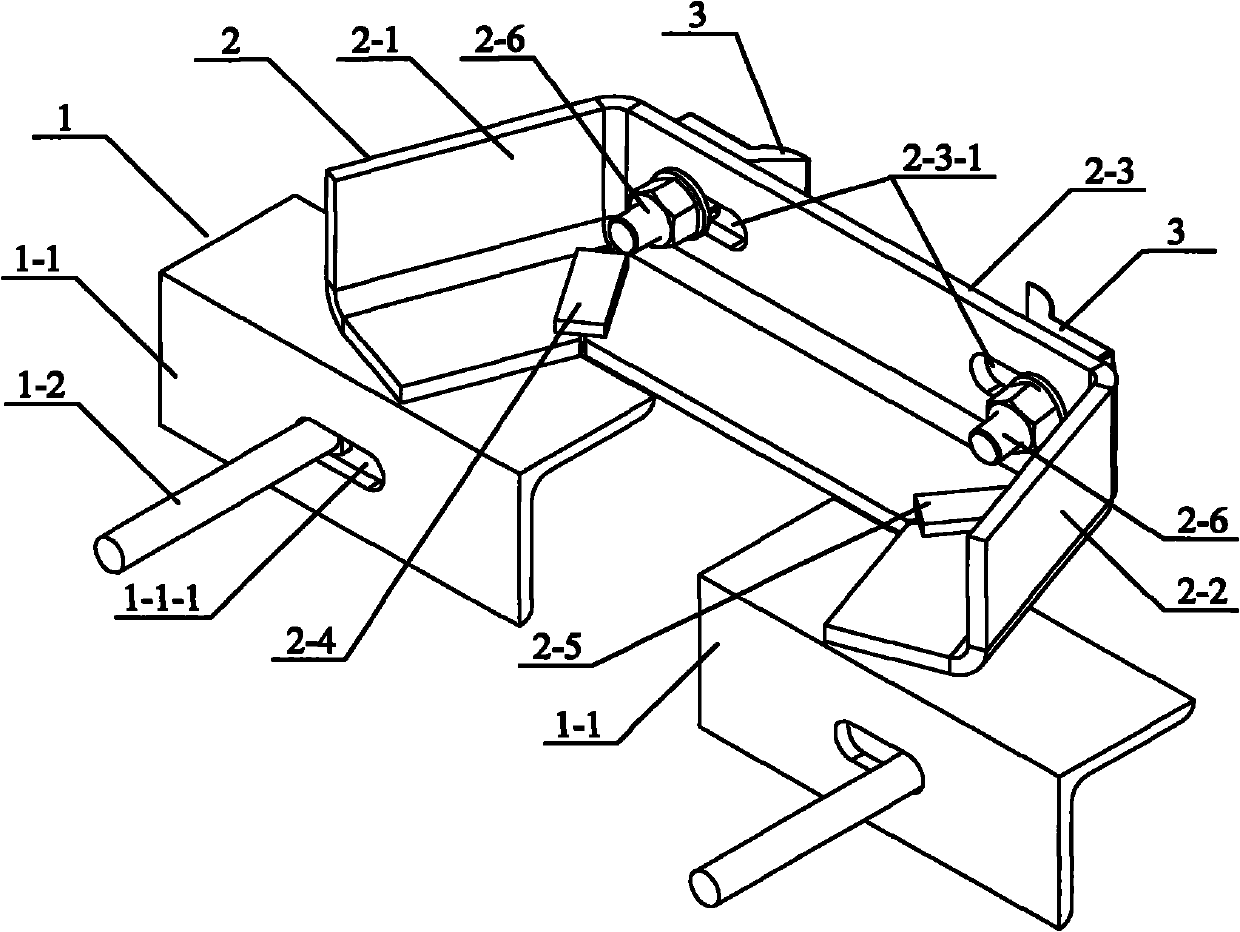

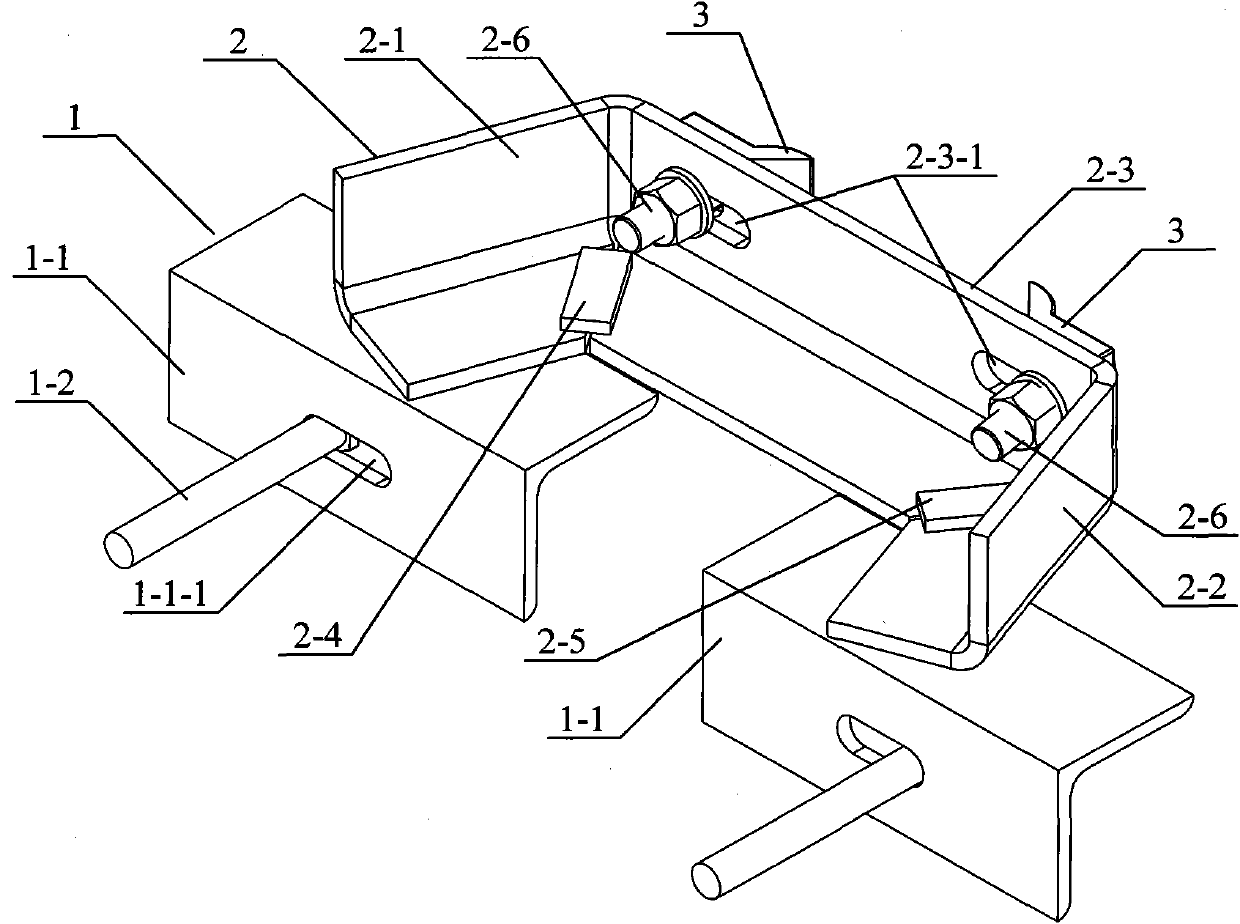

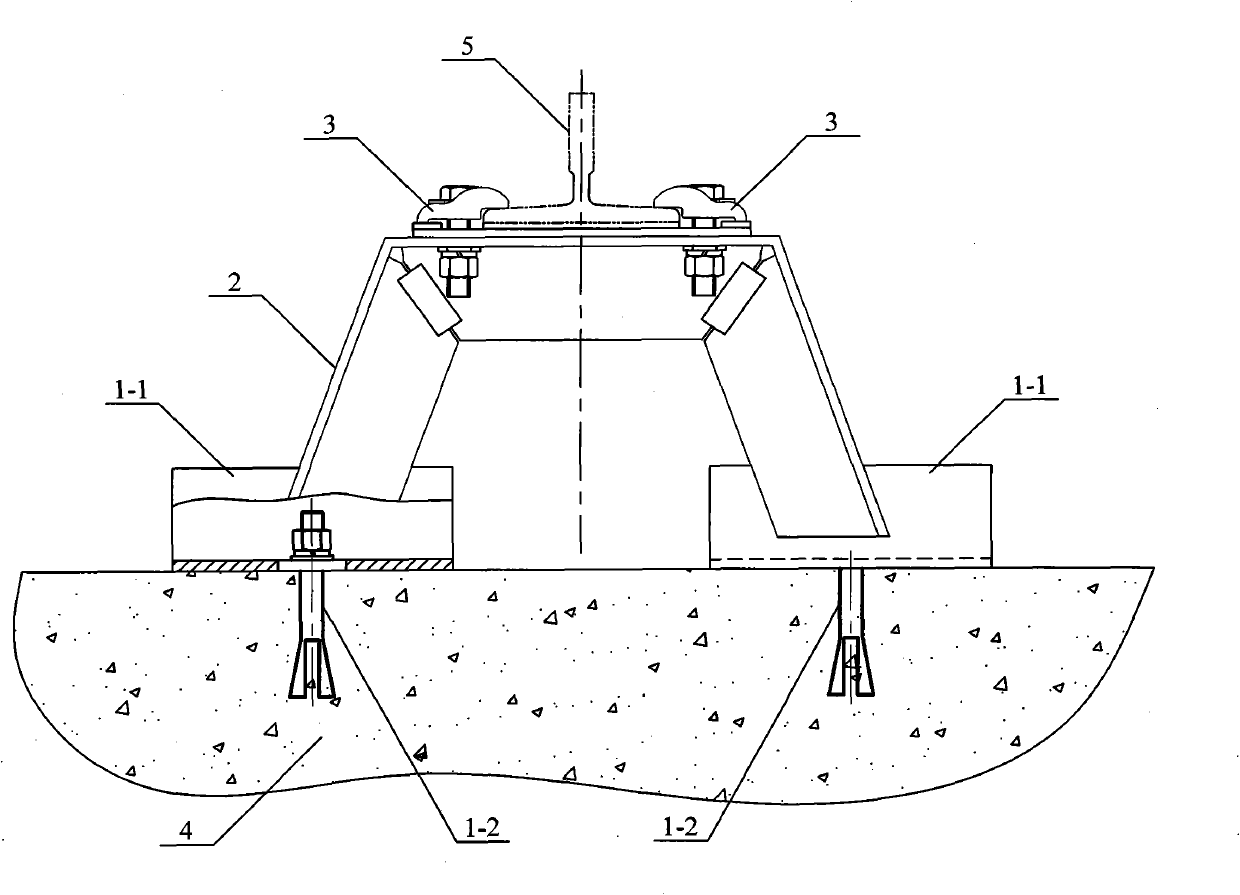

[0019] Such as figure 1 and figure 2 As shown, the adjustable elevator car guide rail support for high-speed elevators in this embodiment includes a fixed support 1 , an adjustment support 2 and a guide rail pressing plate 3 .

[0020] The fixed bracket 1 includes two fixed bracket angle steels 1-1, and expansion bolt connection holes 1-1-1 are provided on the vertical connection surface of each fixed bracket angle steel 1-1. An expansion bolt 1-2 is inserted in each expansion bolt connection hole 1-1-1. Preferably, the expansion bolt connection hole 1-1-1 is a long waist hole.

[0021] The adjustment bracket 2 is a trapezoidal structure formed by bending both ends of the angle steel, which includes the first support arm angle steel 2-1 and the second support arm angle steel 2-2 on both sides, and the angle steel between the above two support arm angle steels. The connecting arm angle steel 2-3 between them is welded at the bent seam. Weld the first reinforcing gasket 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com