Robot sucker claw for coating automobile roof

A technology of robots and suction cups, which is applied in coatings, devices for coating liquid on surfaces, etc., can solve problems such as low glue coating speed, inability to meet vehicle model switching, and difficulties in introducing new models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

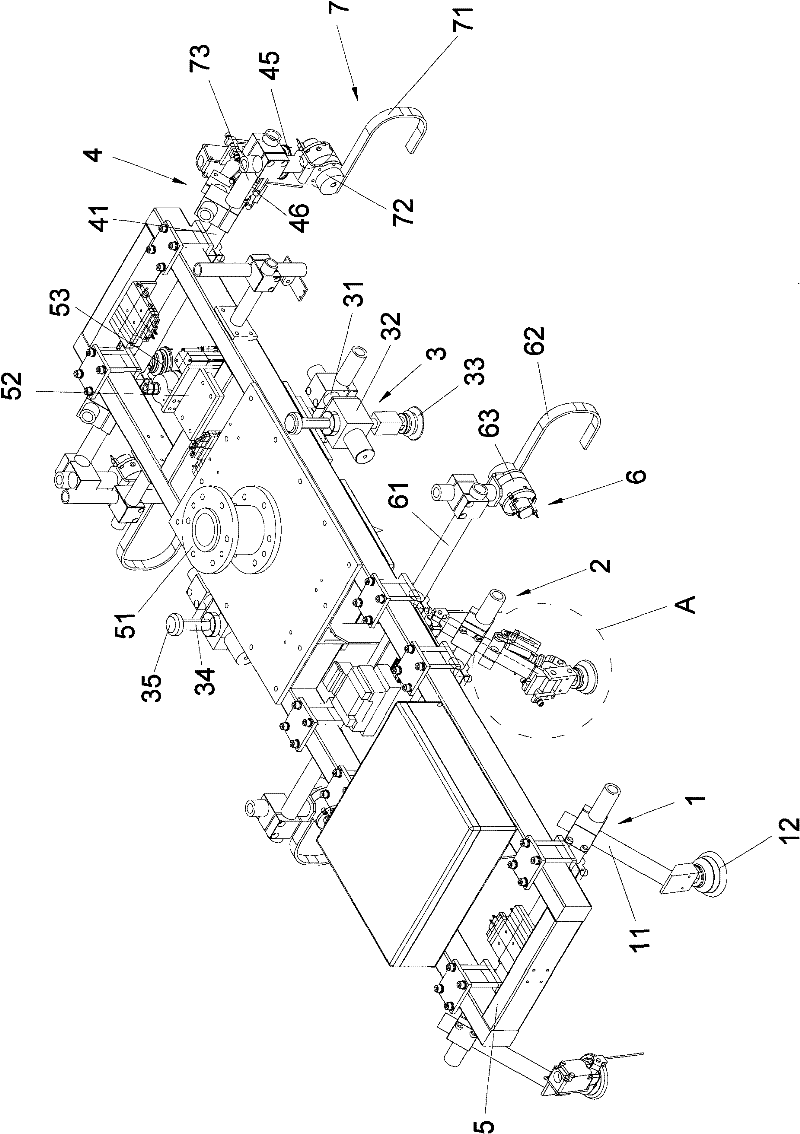

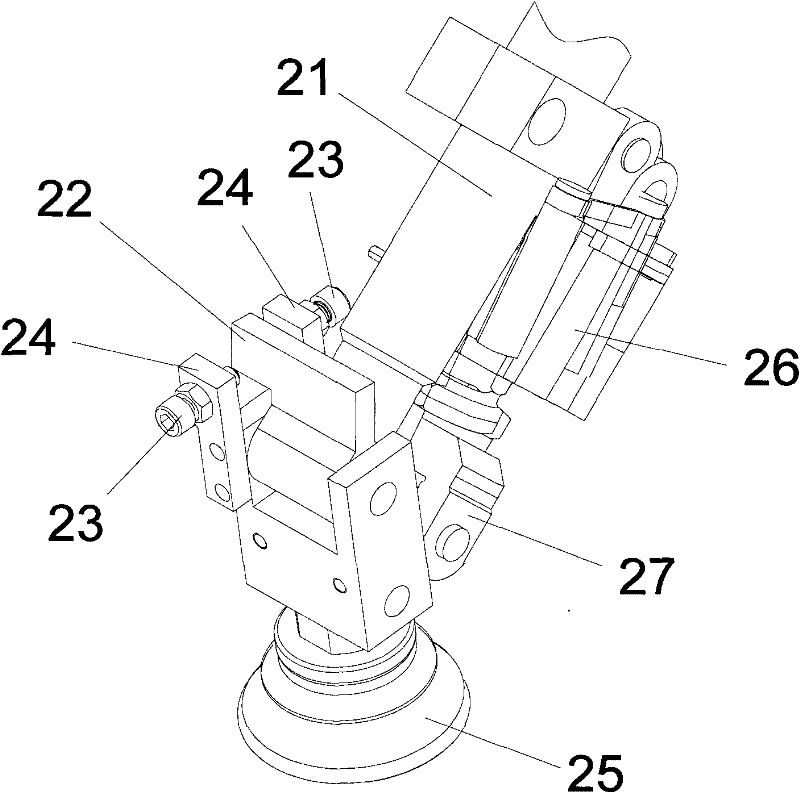

[0036] refer to Figure 4 and Figure 5 1. The working process of the robot's roof gluing suction cup gripper: First, the roof sheet (workpiece) layer is placed on the rack car, and the rack cart is manually pushed into the designated positioning slot. When grabbing the workpiece, the gripper of the robot's roof gluing suction cup first takes a photo of the workpiece above the material rack, and compares the image with the standard image that has been stored in advance, so as to identify the model specification of the workpiece and the actual plane of the workpiece Position, according to the calculation results, the gripper automatically adjusts its posture to grab the workpiece. During the grabbing process, the robot can adjust the angle of the suction cup or adjust the angle of the suction cup by itself for some products with large changes in the curved surface or length of the workpiece, such as the conventional roof 82 and the extended roof 81, according to the different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com