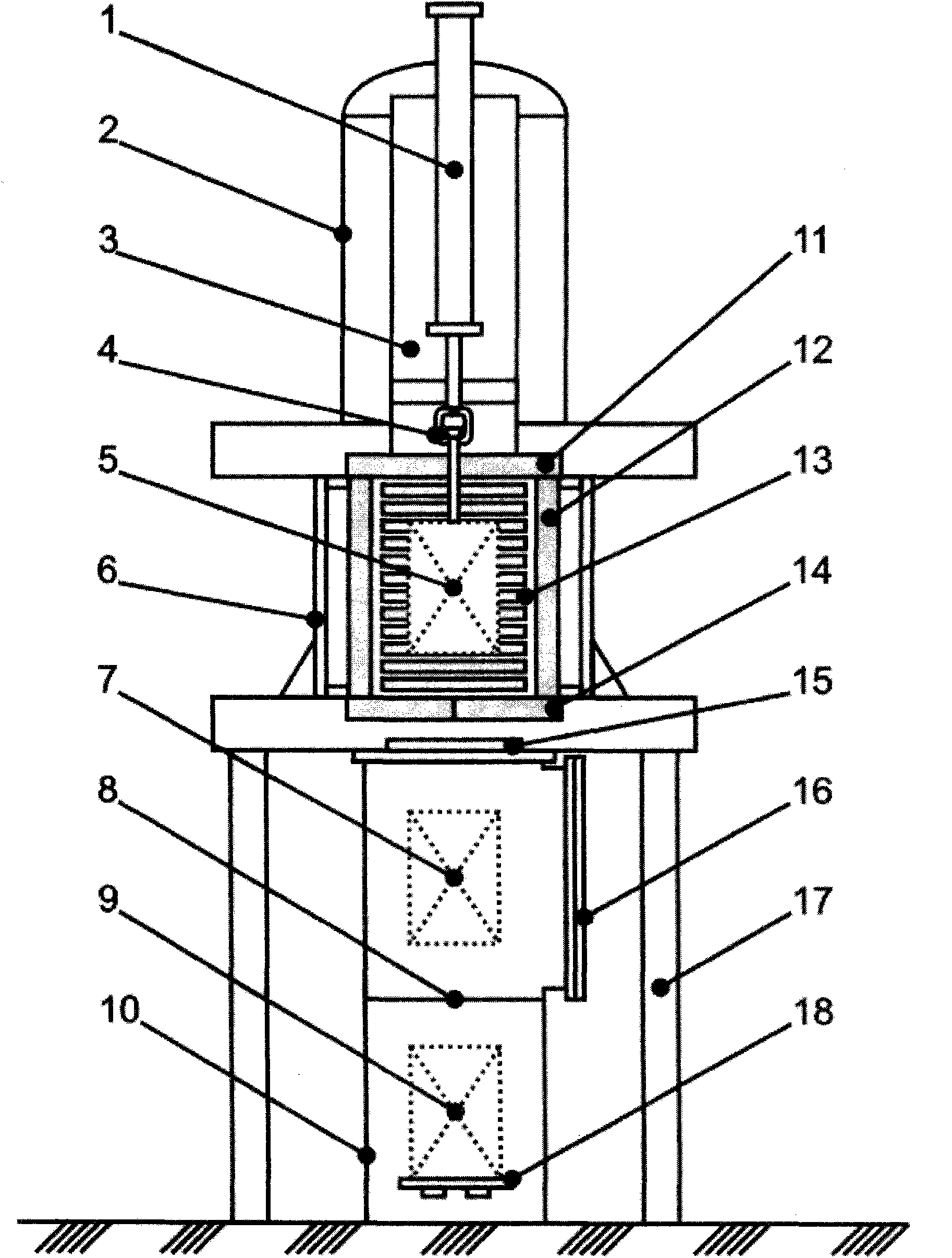

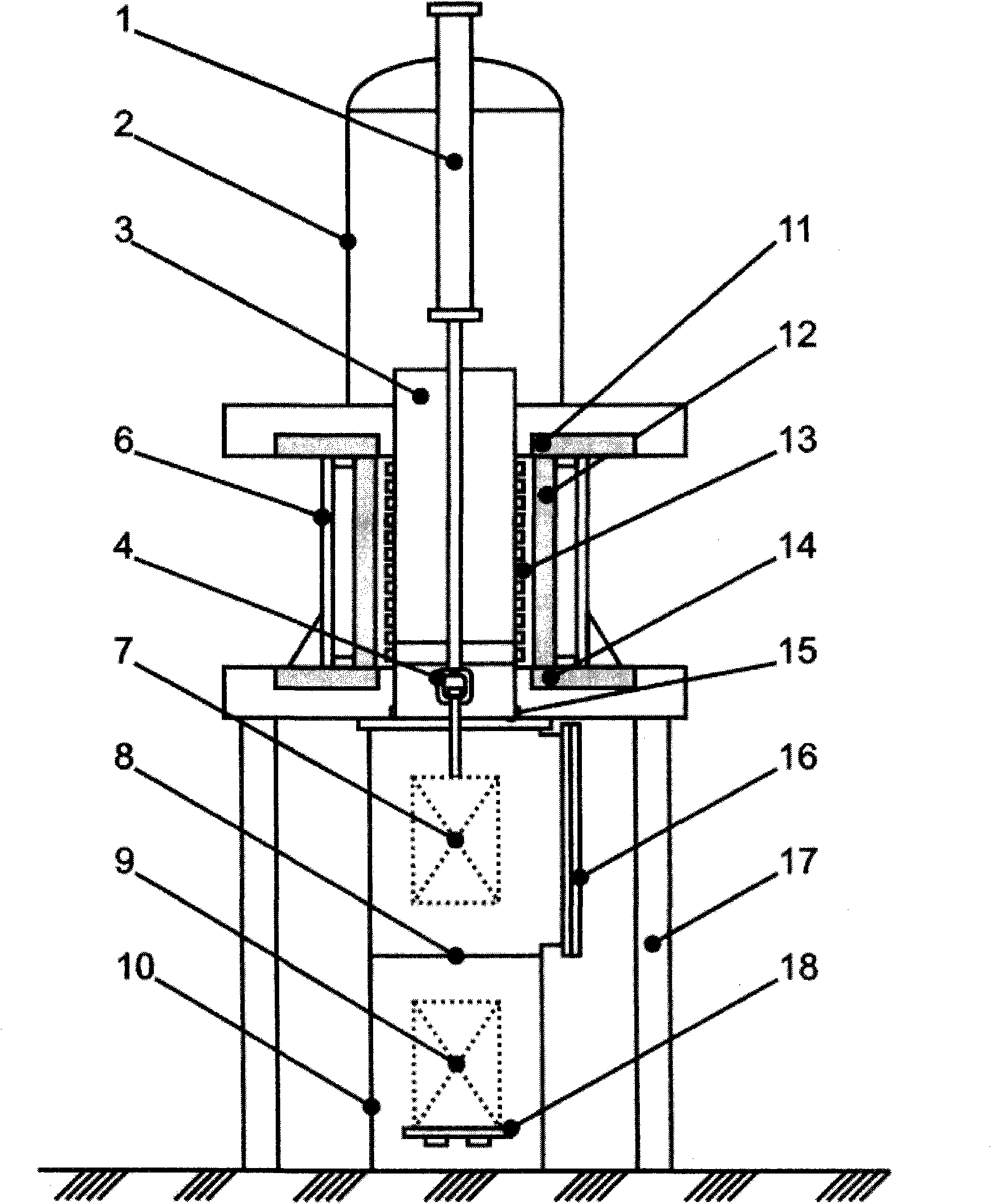

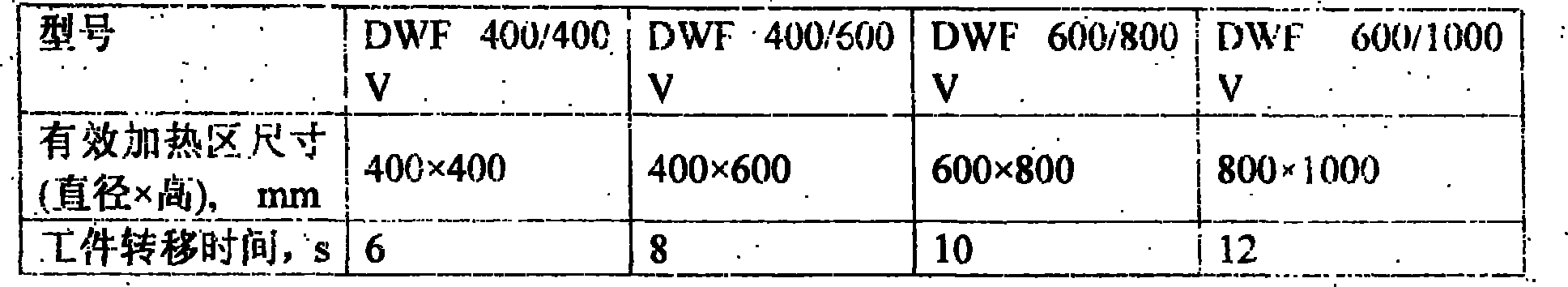

Vertical vacuum water quenching furnace

A technology of water quenching furnace and vacuum, which is applied in the field of vertical vacuum water quenching furnace, which can solve the problems of low productivity, high heating temperature, large direct heat dissipation of furnace tank, etc., and achieve the effect of large heating zone size and high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] As another implementation method of the present invention, the lower heat-insulation door and the lower airtight door can be combined into one body, and a lower heat-insulation airtight door can realize heat insulation and sealing at the same time.

[0048] The third implementation method

[0049] In the present invention, the quenching mechanism located above the furnace body is equipped with the charge and the isolated air pump at the same time. As the third implementation method of the present invention, these two mechanical actions can be separated, and the mechanism located above the furnace body is only mounted with the isolated air pump. The lifting mechanism located in the quenching water tank completes the mechanical action of lifting the charge into and out of the heating chamber and the quenching water tank. In this case, the lower insulation door and the lower airtight door cannot be combined into one body. The lower insulation door must adopt a double-open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com