Low-permeability reservoir bed starting pressure testing method

A low-permeability reservoir and start-up pressure technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large differences between experimental conditions and reservoir conditions, and can not simulate the high-pressure conditions of the reservoir more realistically, so as to eliminate the end-face effect , the effect of small test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The temperature-resistant and pressure-resistant long core holder with 9 pressure measuring points is used, and the outcrop long core with a specification of 4.5×4.5×100cm is used (there is no butt joint in the whole, which eliminates the influence of the end surface effect and is closer to the actual reservoir conditions), and the experimental confining pressure is 32MPa , the test medium is simulated formation water with a salinity of 20000mg / L and a viscosity of 0.98mPa.S.

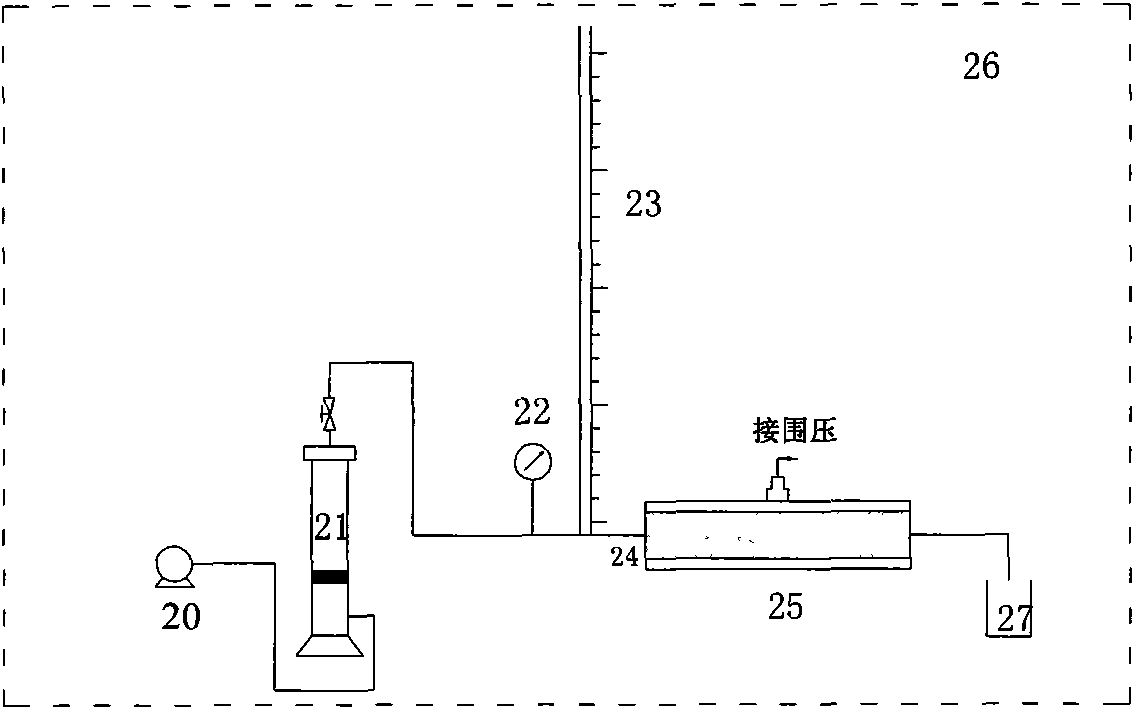

[0027] The test device includes a displacement pump (ISCO pump) 30, an intermediate container 31, a core holder 37, a constant temperature box 33, a confining pressure pump (not shown in the figure), a back pressure valve 34, a production fluid collection device 35, a pressure automatic Acquisition instrument 36 starts the pressure gradient test process, see Figure 5 .

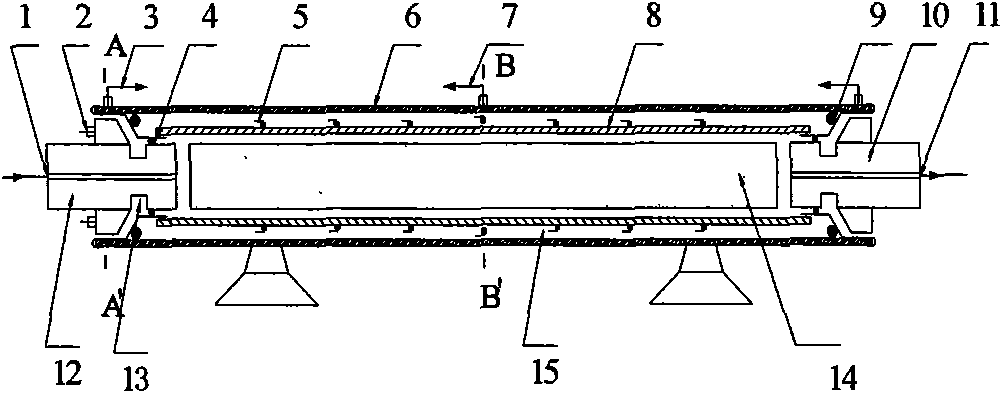

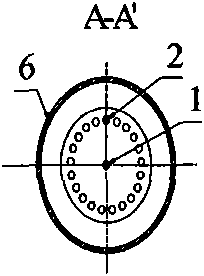

[0028] The structure of the core holder is as follows Figure 2~4 As shown, it includes a stainless steel shell 6, a rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com