Electronic weigher

An electronic scale and weight sensor technology, applied in the field of measuring instruments, can solve the problems of unstable center of gravity of the system and affect the measurement accuracy, and achieve the effects of novel structure, overcoming low weighing accuracy and high weighing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

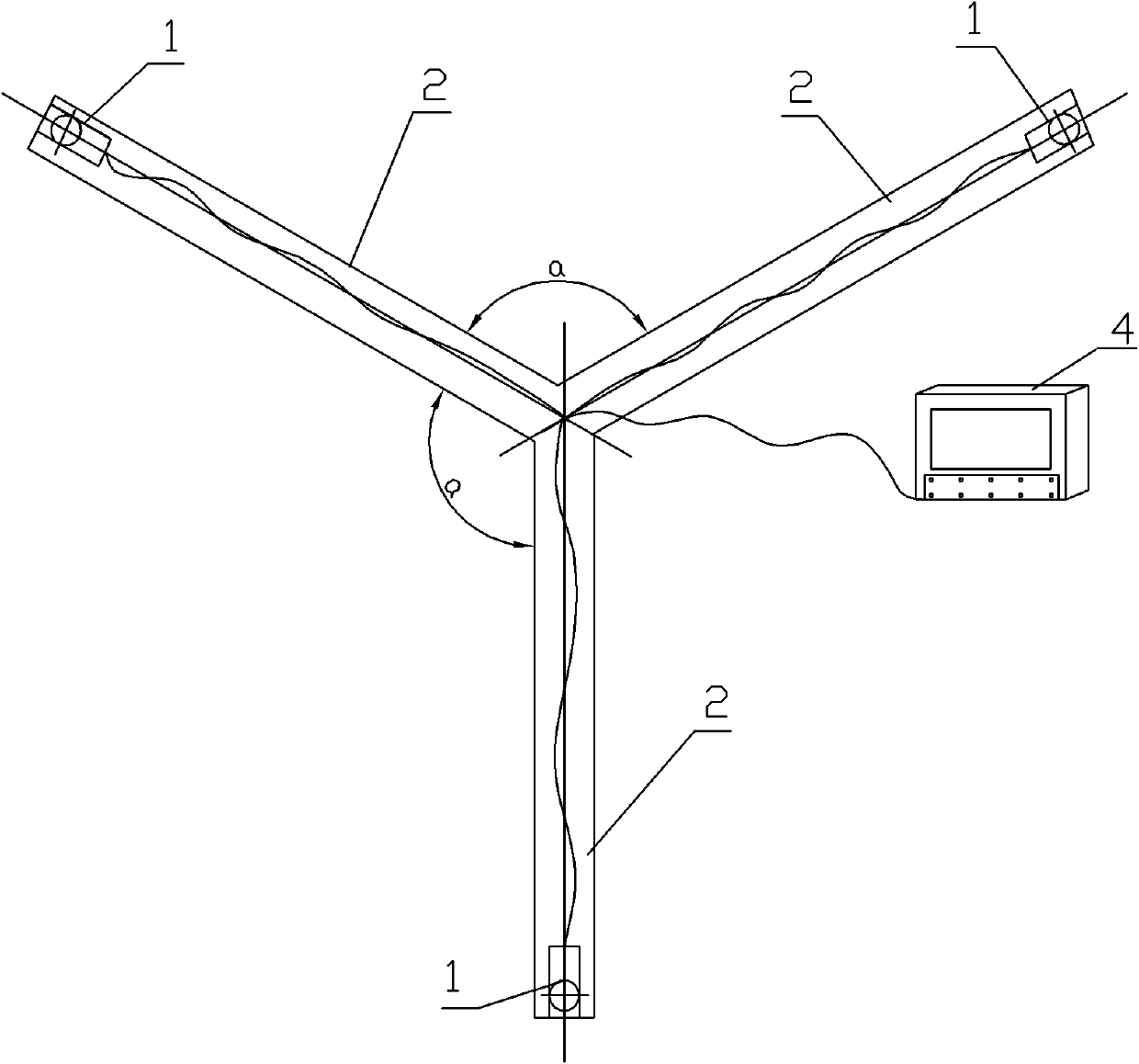

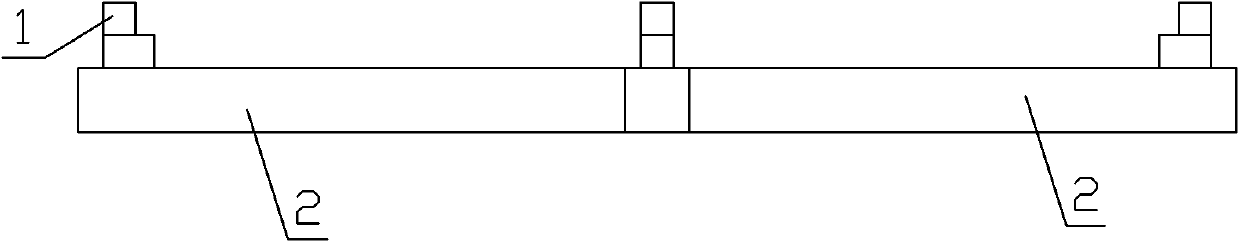

[0008] Embodiment 1: The electronic scale described in this embodiment is composed of a support structure and three weight sensors 1, the support structure is composed of three equal-length channel steels 2, and one end of the three channel steels 2 is fixedly connected together, And the included angle between any two adjacent channel steels 2 is 120°, and the three weight sensors 1 are respectively fixed on the upper surfaces of the three channel steels 2 .

[0009] In this embodiment, the fixed connection of the three channel steels 2 can be fixed by welding, so that the connection strength of the three channel steels 2 is high.

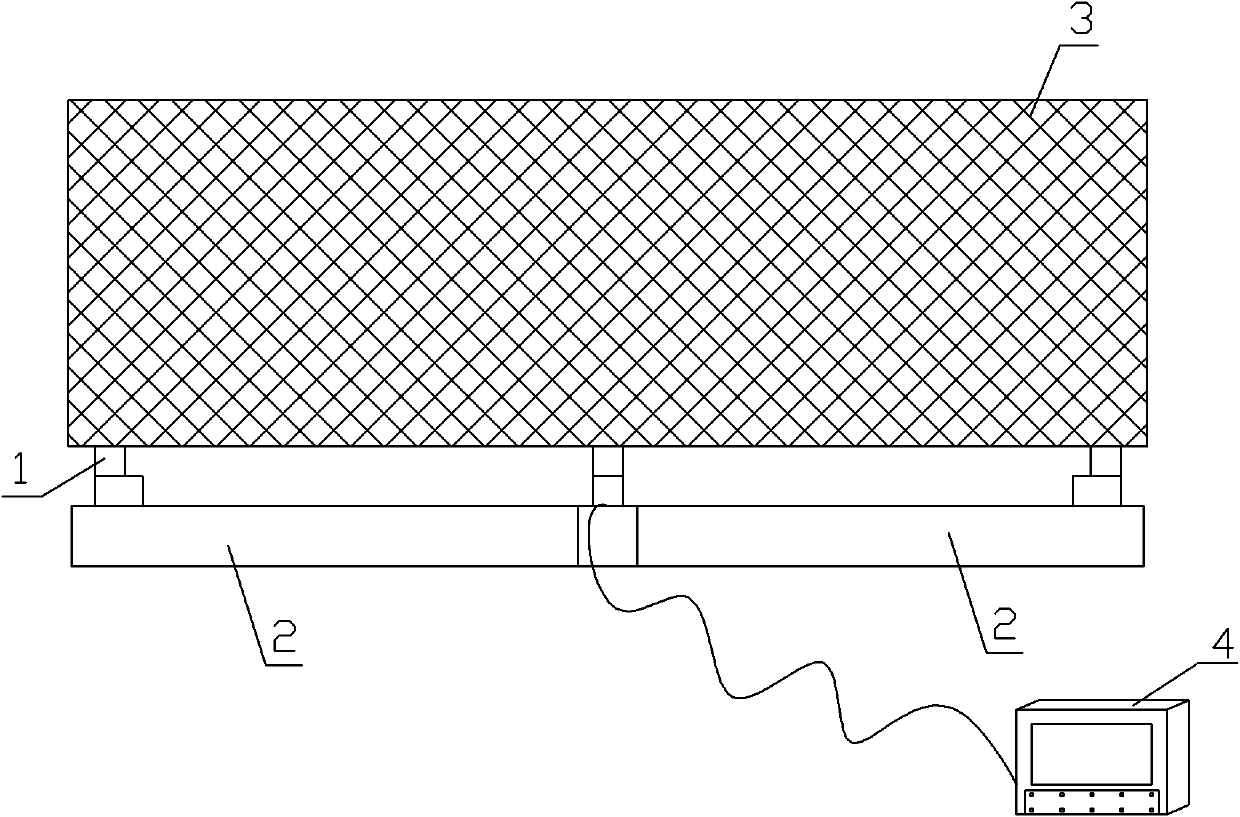

[0010] When the electronic scale described in this embodiment is in use, the object 3 to be measured is directly placed on the support frame, and directly contacts with the three weight sensors 1 to realize weighing. The signal output terminals of the three weight sensors 1 can be connected with the current The measurement display device connected ...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment is the electronic scale described in Embodiment 1. The difference is that the three weight sensors 1 are at the same distance from the joints of the three channel steels 2 .

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and the electronic scale described in specific embodiment one or two is that the electronic scale also includes a data collector 4, and the data acquisition device 4 communicates with three weights through three data lines. The weight signal output end of the sensor 1 is connected, and the data collector 4 has a measurement data output port.

[0013] In this embodiment, a data collector 4 is added, and the data collector 4 is used to collect the weight signals of the three weight sensors 1, and calculate and obtain the measured weight signal according to the three collected weight signals. The data collector 4 added in this embodiment has a measurement data output port. In actual use, the data output port can be connected with devices such as a display, a data storage device, and a printing device to realize display, storage or printout of the measured weight information. , It can also be connected with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com