Device and method for dilution of cellulose pulp

A cellulose pulp and pulp technology, which is applied in pulp dehydration, washing/replacement of pulp treatment liquid, etc., can solve the problem of limited maximum amount of diluted liquid, and achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

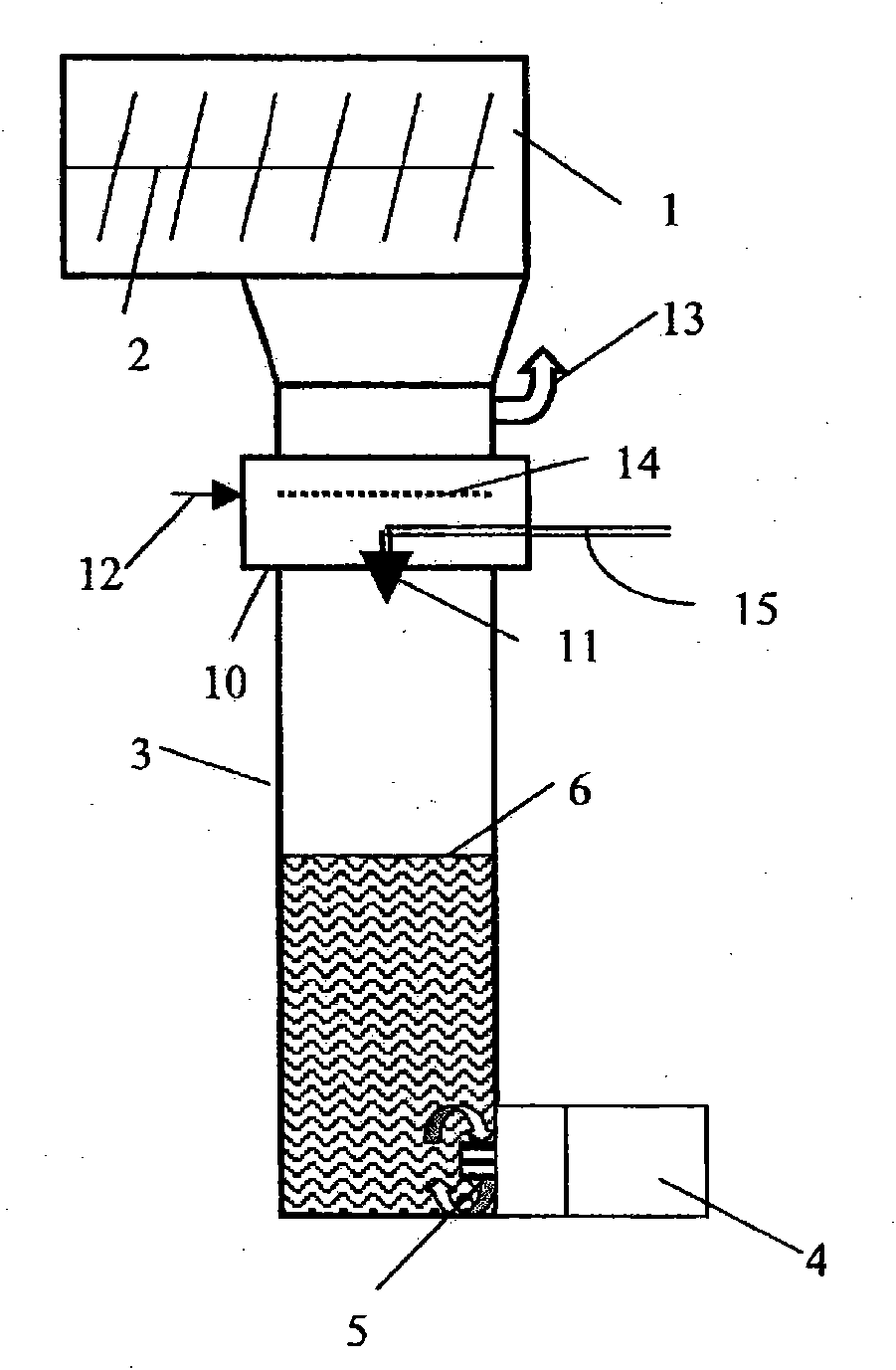

[0015] figure 1 Indicates a position on a pulp production line where broken cellulose pulp in the form of flocs is conveyed in a screw feeder 1 where a feed screw 2 feeds the flocs of cellulose pulp Sent to pulp chute 3. The screw feeder 1 can constitute the final part of the pulp breaker or conveying screw in a bleaching reactor in which the cellulose pulp is bleached at a high consistency of at least 20%.

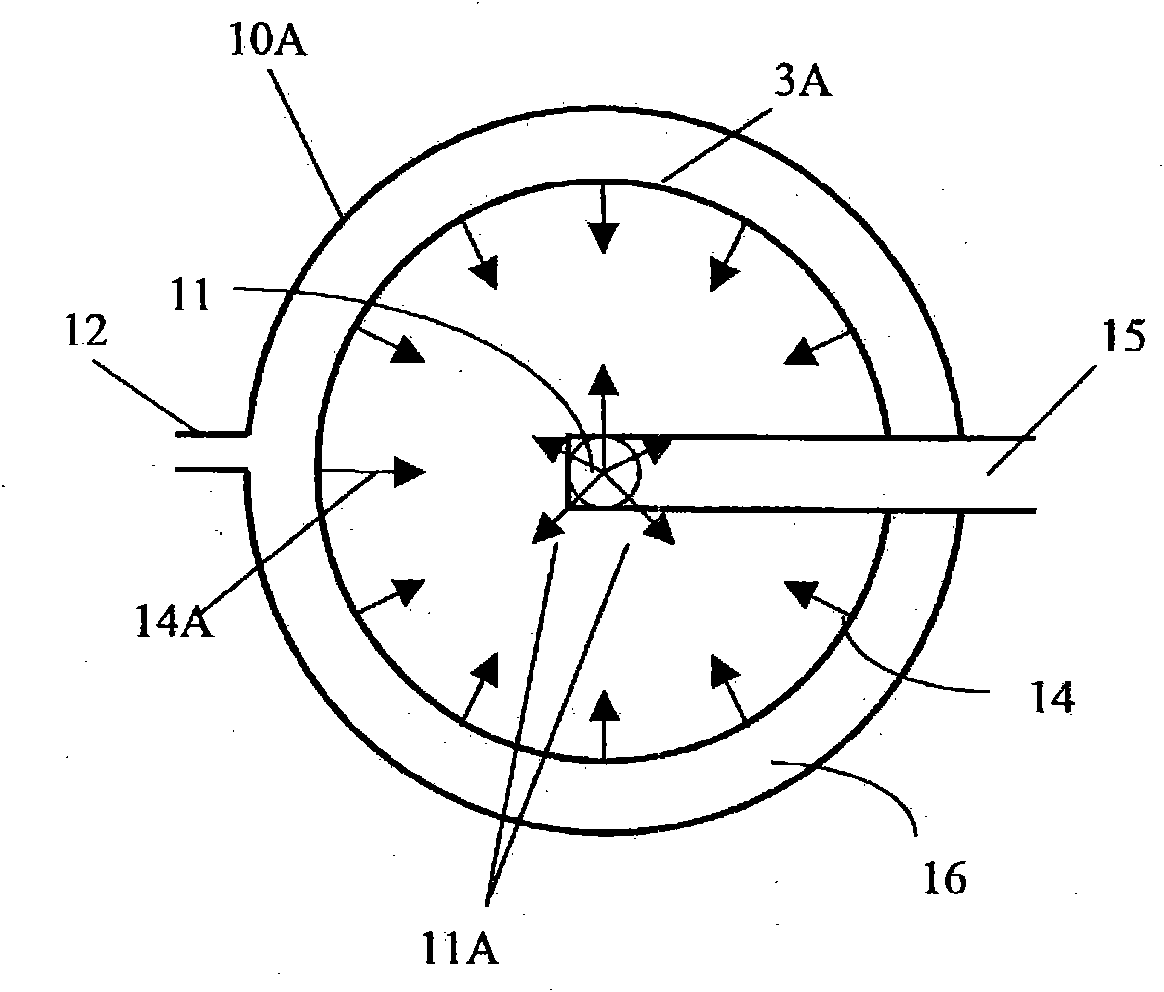

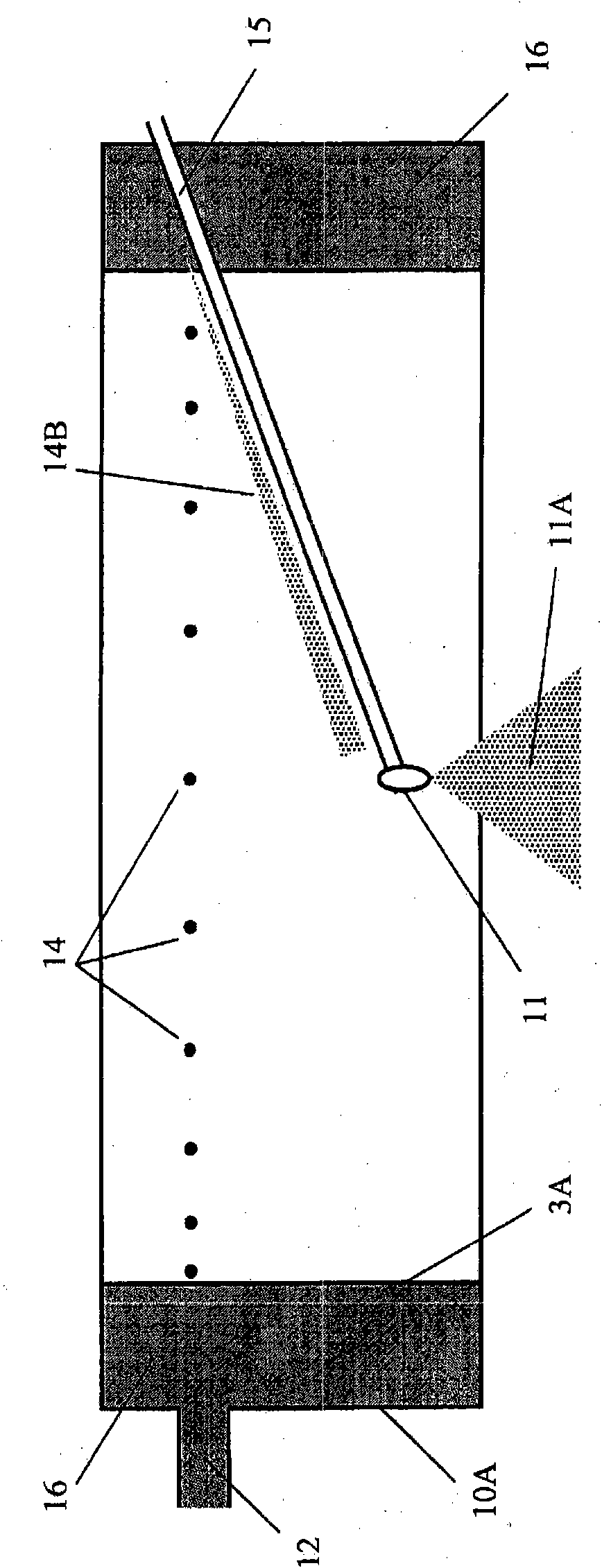

[0016] The dilution device 10 is arranged on the upper part of the pulp chute 3, and the dilution device 10 adds dilution liquid to the floc flow, while the floc flow freely falls to the pulp liquid level 6 established in the pulp chute 3. The dilution device 10 comprises a line 15 routed to a central distribution device with nozzles 11 arranged in the center of the pulp chute 3 in order to distribute the dilution liquid as the cellulose pulp falls freely along the center of the pulp chute 3 in cellulose pulp. Furthermore, in the shown embodiment there is also a supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com