Separable power plug/socket connecting structure of electric frying pan

A connecting structure and plug-connecting technology, which is applied in the direction of connecting and connecting parts, circuits, etc., can solve the problems of non-detachable, difficult to replace, and affect use, and achieve the effects of improving safety, convenient storage, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

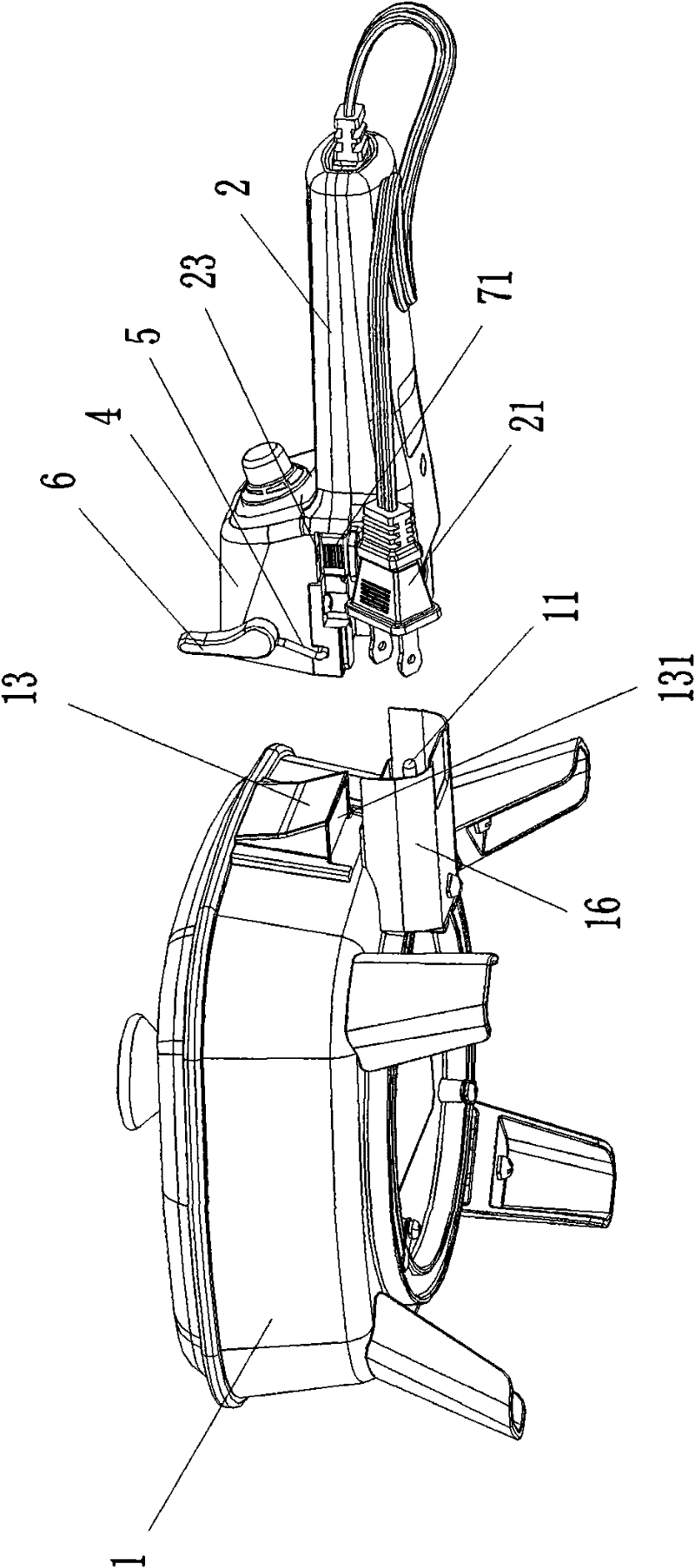

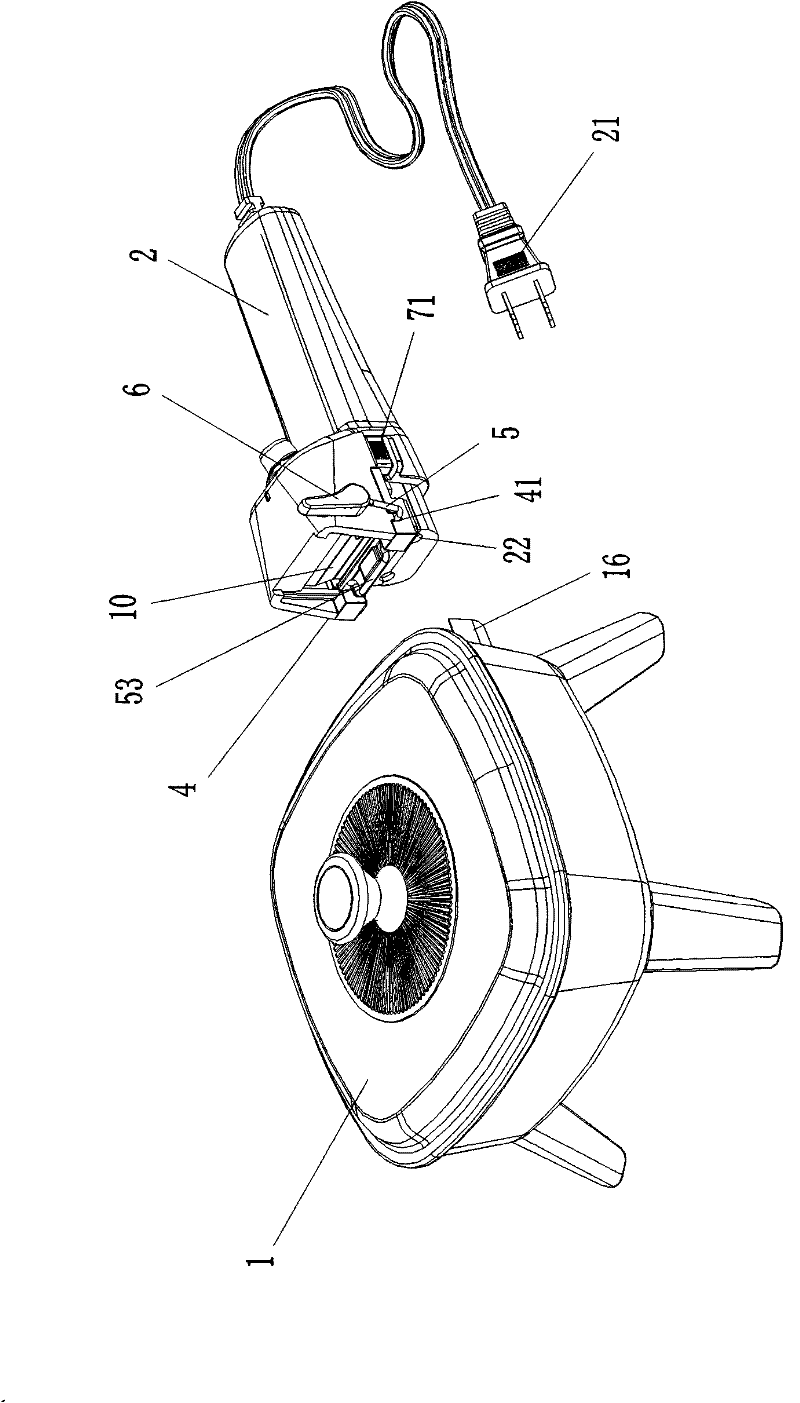

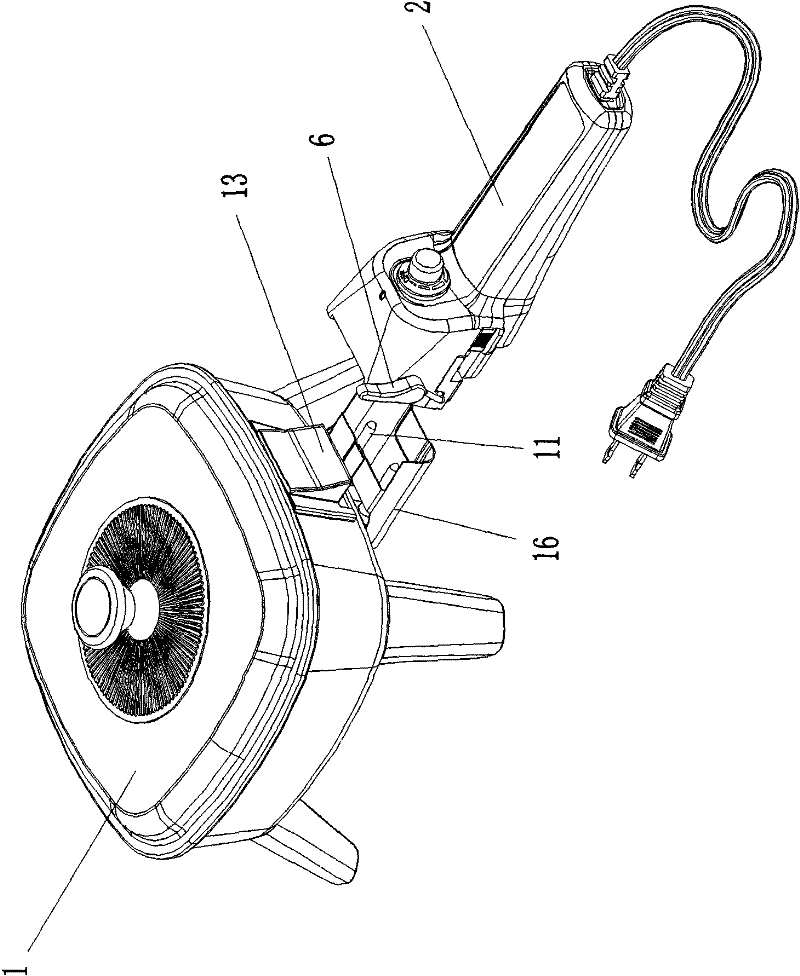

[0027] Such as Figure 1 to Figure 7 As shown, a detachable power plug / socket connection structure for an electric frying pan, including a pot body 1 and its movable handle 2, an external power input plug 21 is installed at one end of the movable handle 2, and a socket 22 is installed at the other end. The heating element at the bottom of the pot body 1 extends out a plug 11 that can be plugged and matched with the socket 22. The pot body 1 is provided with a limit bump 13 near the position of the plug 11, and the movable handle 2 The end of the socket 22 is provided with a terminal holder 4, and the position of the corresponding limit projection 13 on the terminal holder 4 is installed on the movable rocker 5, so that the socket 22 on the movable handle is mated with the socket 11 on the pot body. , by adjusting the movable rocker 5 so that the movable rocker 5 locks the limit projection 13 on the pot body 1 . Wherein, the movable rocker 5 is twisted into an elbow with a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com