Method for determining flexural capacity of metal faced straw sandwich board and application thereof

A determination method and technology of sandwich panels, which are applied in the direction of applying stable bending force to test the strength of materials, buildings, building components, etc., can solve the problem of inability to determine the bending bearing capacity, and achieve the effect of accurate evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

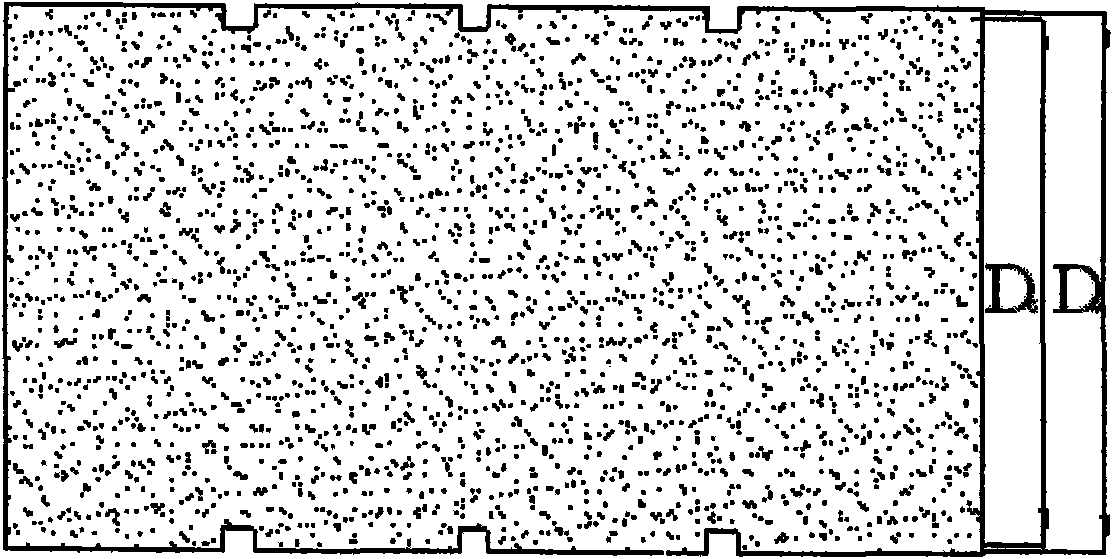

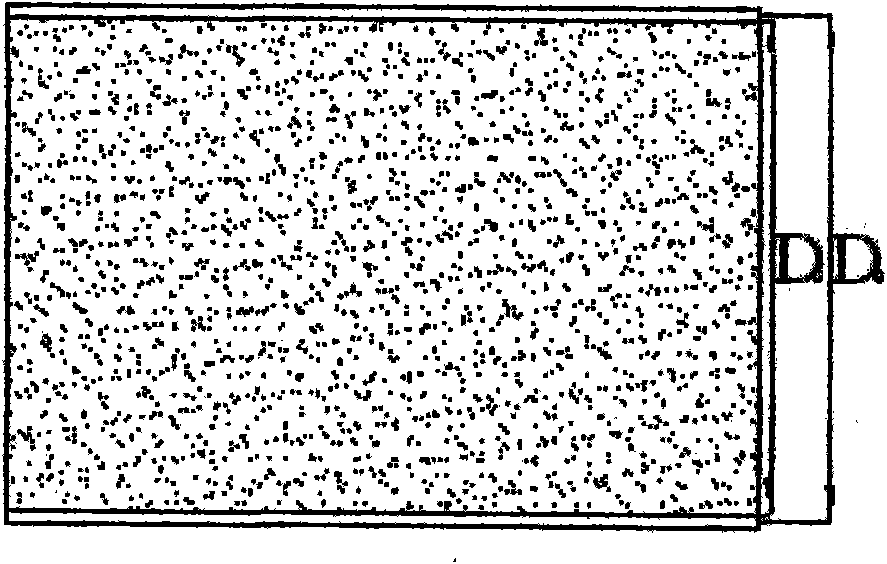

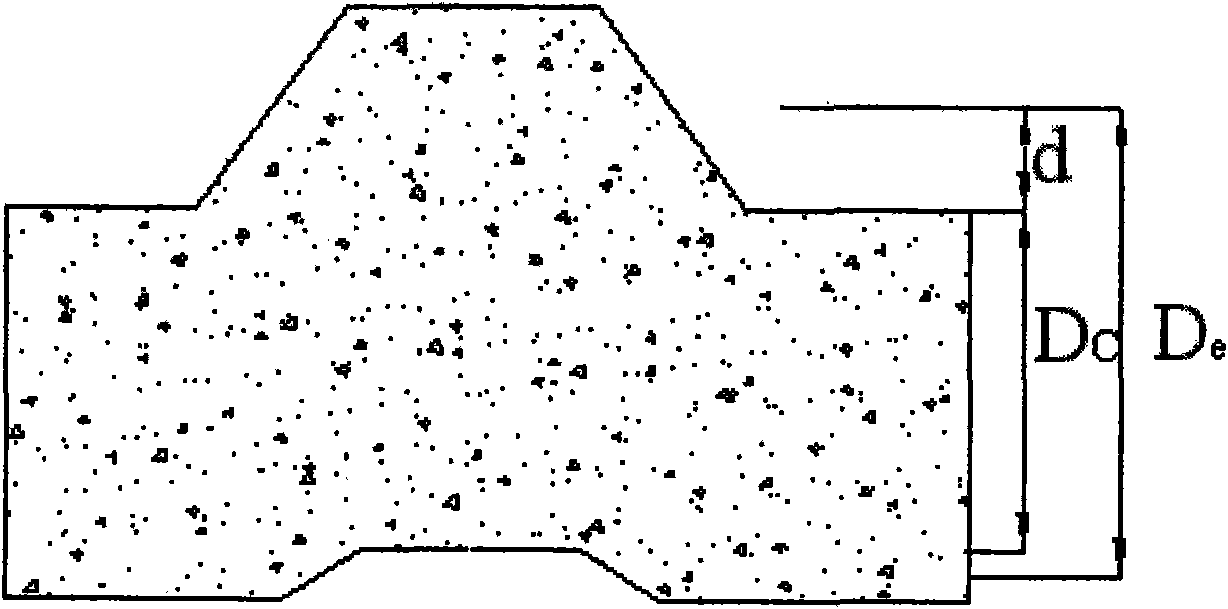

[0042] The following table shows the parameters and meanings used in the drawings of the specification and the specification in the patent document of the present invention:

[0043] p

Surface load standard value, unit KN / m 2 ;

b

The width of the sandwich panel, in mm;

L

The span of the sandwich panel, in mm;

D c

Core material thickness, in mm;

D h

Sandwich panel thickness, in mm;

D e

Sandwich panel effective thickness, D e =(D c +D h ) / 2, unit mm;

t

Panel thickness, in mm;

E 1

The modulus of elasticity of the surface material, in MPa;

E 2

Elastic modulus of the core material, in MPa;

K

Bending stiffness of the sandwich panel, mm 2 ;

K C

Stiffness of sandwich part, mm 2 ;

K D

The st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap