Method for determining flexural capacity of aluminum sandwich panel and application

A method to determine the bearing capacity, applied in the direction of using a stable bending force to test the strength of materials, roofs using flat/curved panels, roofs, etc., to achieve the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below with reference to specific embodiments.

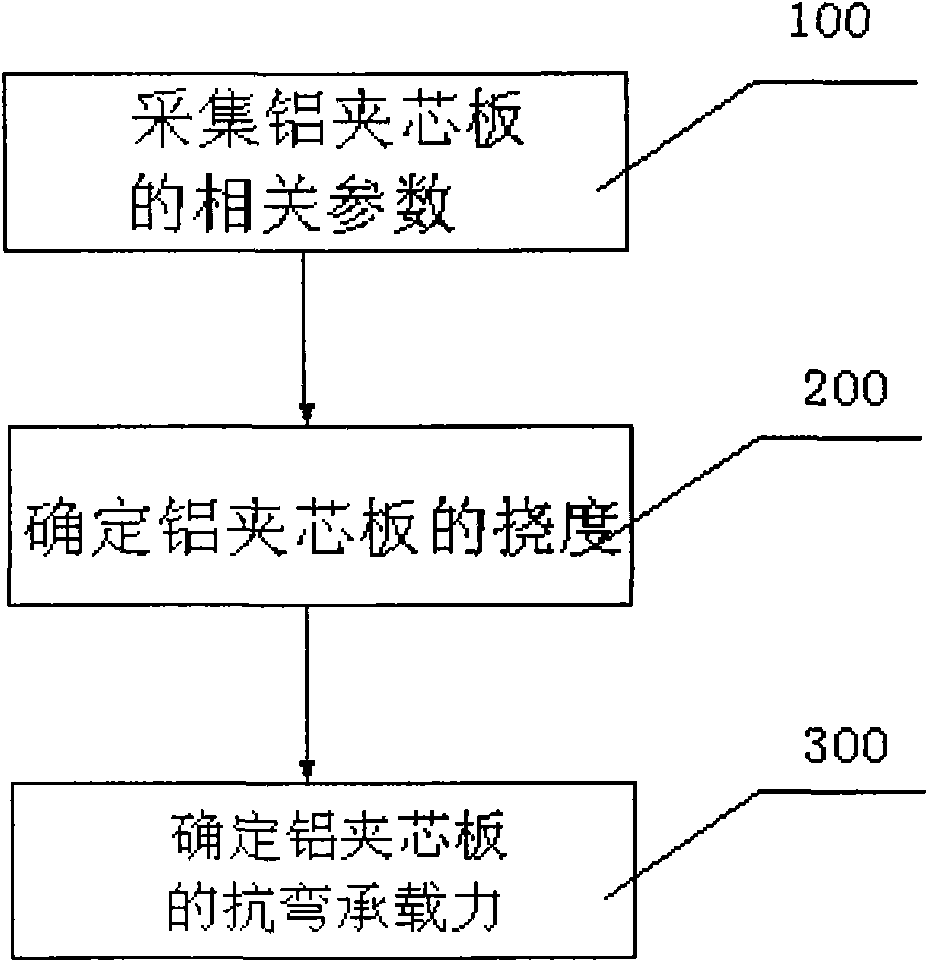

[0047] like figure 1 As shown in the figure, the specific embodiment of the present invention is to provide a method for determining the flexural bearing capacity of an aluminum sandwich panel, wherein the front panel of the aluminum sandwich panel is an aluminum panel, and the core panel of the aluminum sandwich panel is an intermediate layer through adhesive bonding. Binder bonding or casting. In the present invention, the aluminum sandwich panel specifically includes a wall panel and a roof panel.

[0048] The method for determining the flexural bearing capacity of an aluminum sandwich panel includes the following steps:

[0049] Step 100: Collect relevant parameters of the aluminum sandwich panel: collect the span of the aluminum sandwich panel, the width of the aluminum sandwich panel, the rigidity of the aluminum sandwich panel, the rigidity...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap