A centrifugal separator

A centrifugal separator and separation chamber technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

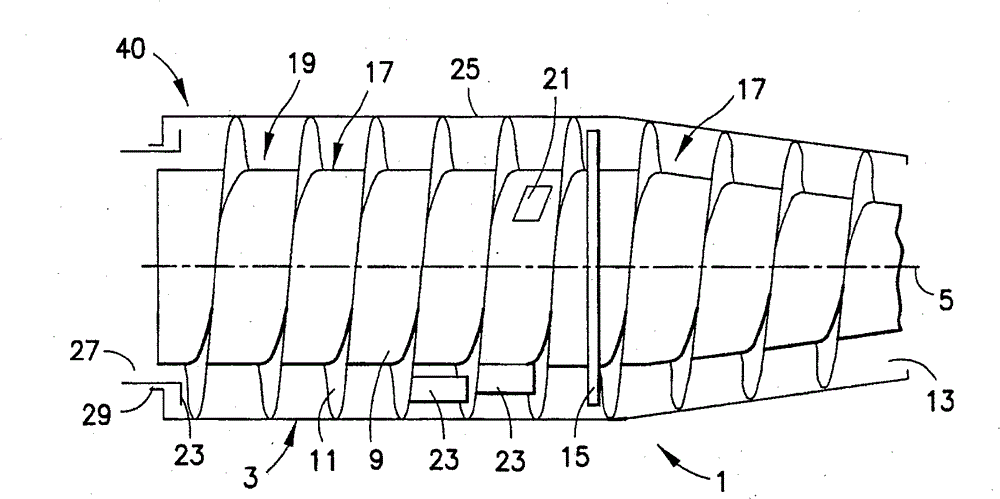

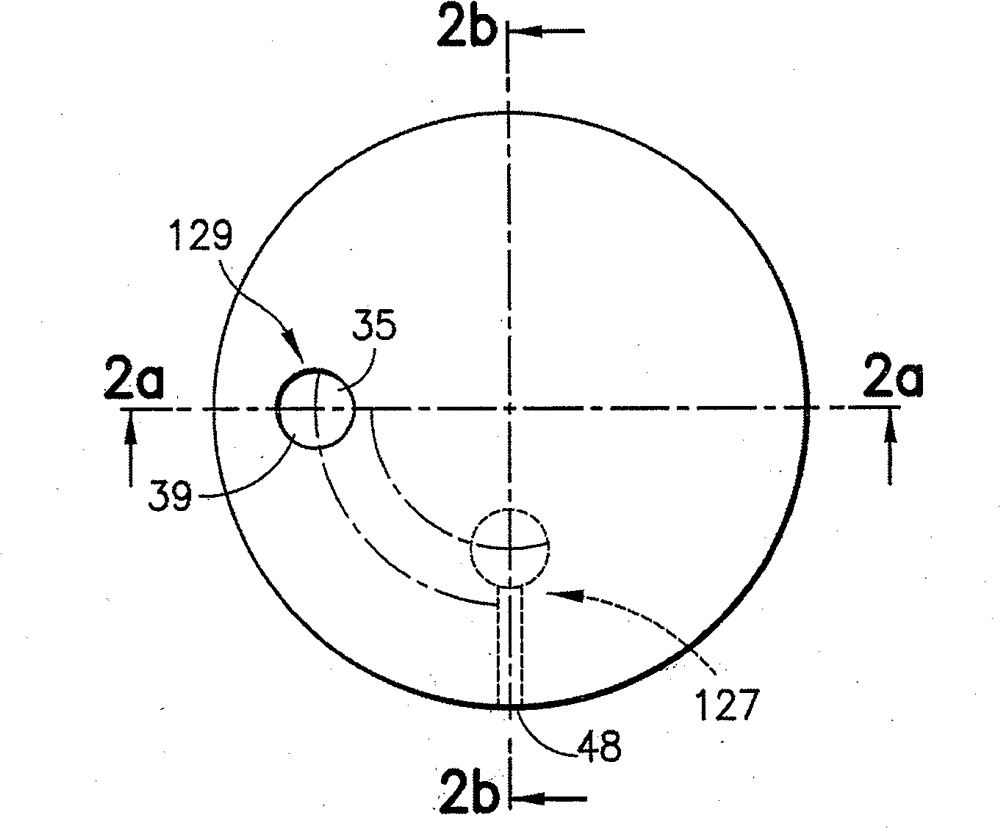

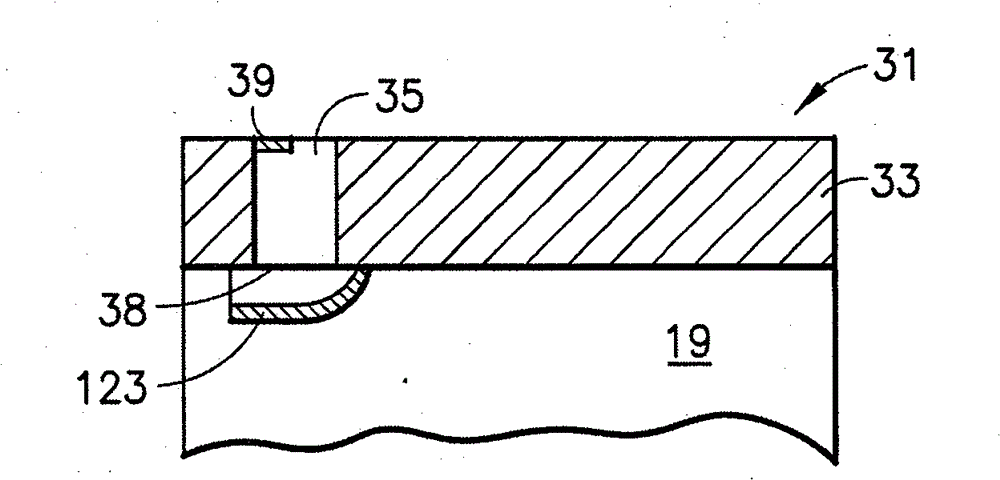

[0028] figure 1 A centrifugal separator or centrifuge 1 in which the invention can be applied is schematically shown. The centrifuge 1 comprises a drum or drum 3 which rotates during operation about a longitudinal axis of rotation 5 extending in the longitudinal direction of the drum. In the drum 3 is arranged a screw conveyor 7 comprising an elongated body 9 carrying a worm 11 for transporting the solid phase of the material separated in the centrifuge towards a solid phase outlet 13 . A partition 15 divides the interior of the drum 3 into a solid phase outlet segment 17 and a separation chamber 19 . The elongated body 9 includes an inlet 21 for the material to be separated by the centrifuge. A barrier plate 23 is provided in the separation chamber 19 to enable separation of the liquid phase of the material in the separation chamber 19 into a light liquid phase and a heavy liquid phase. Due to the different densities, the heavy liquid phase will be placed closer to the cir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap