Steam hanging iron and water deficiency automatic protection method thereof

An automatic protection and garment steamer technology, applied in washing devices, hand irons, textiles and papermaking, etc., can solve the problems of the garment steamer not working normally, poor safety and reliability, damage to the steam generator, etc., to achieve protection The design is more humanized, the accuracy is improved, and the operation and use are safe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

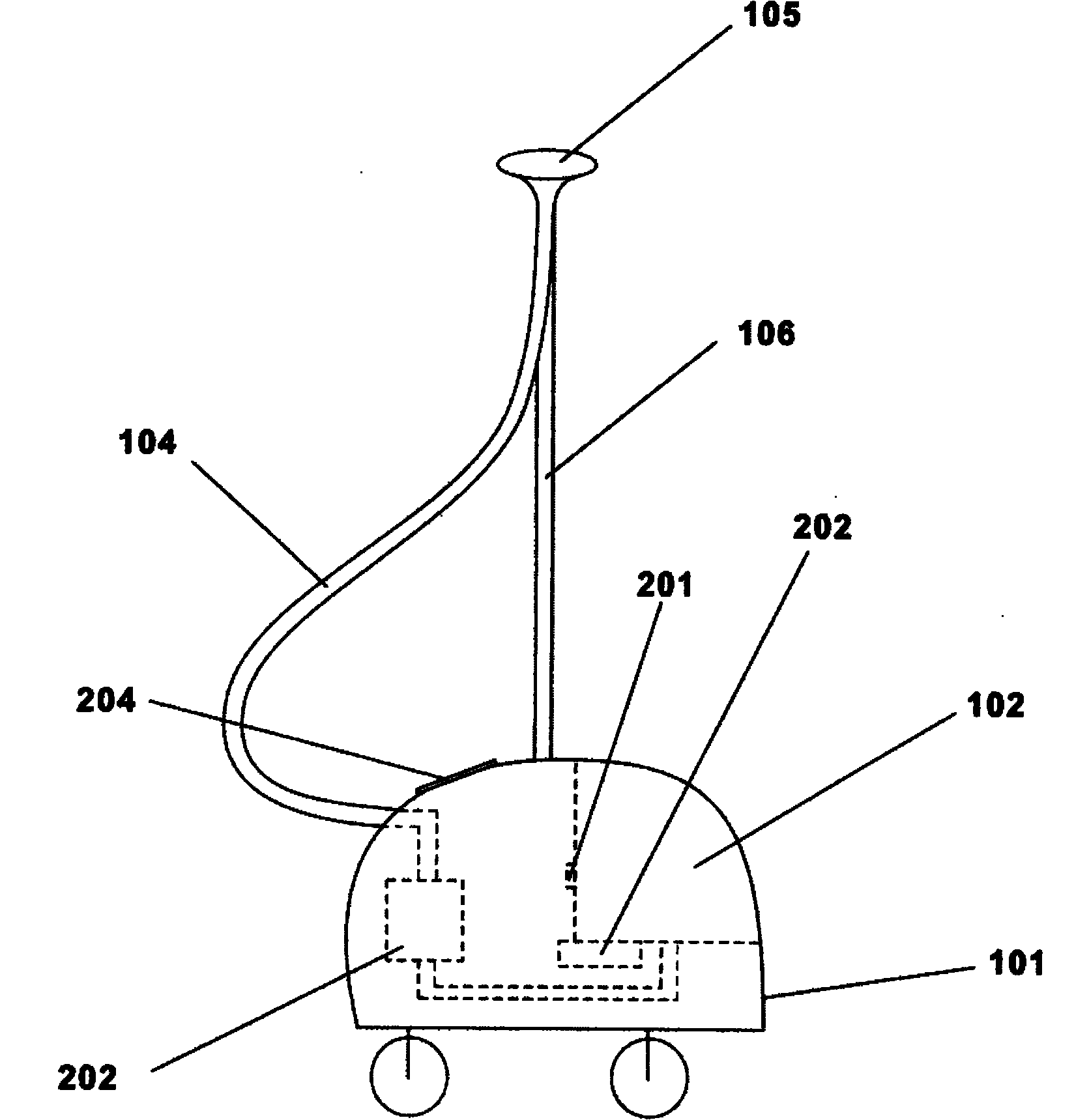

[0028] Such as figure 1 As shown, the garment steamer of the present invention includes a housing 101, a water tank 102, a steam generator 103, a steam transmission pipe 104, a nozzle 105, a support rod 106 and an automatic protection device for water shortage. The device 103 supplies water, and the steam generator 103 heats the water so that it is vaporized into steam at about 98 degrees, and then the steam is delivered to the nozzle 105 through the steam transmission pipe 104 to eject, so as to realize the steam treatment of the fabric. When the nozzle 105 is not in use or in a non-handheld state, it can be placed on the support rail 106 .

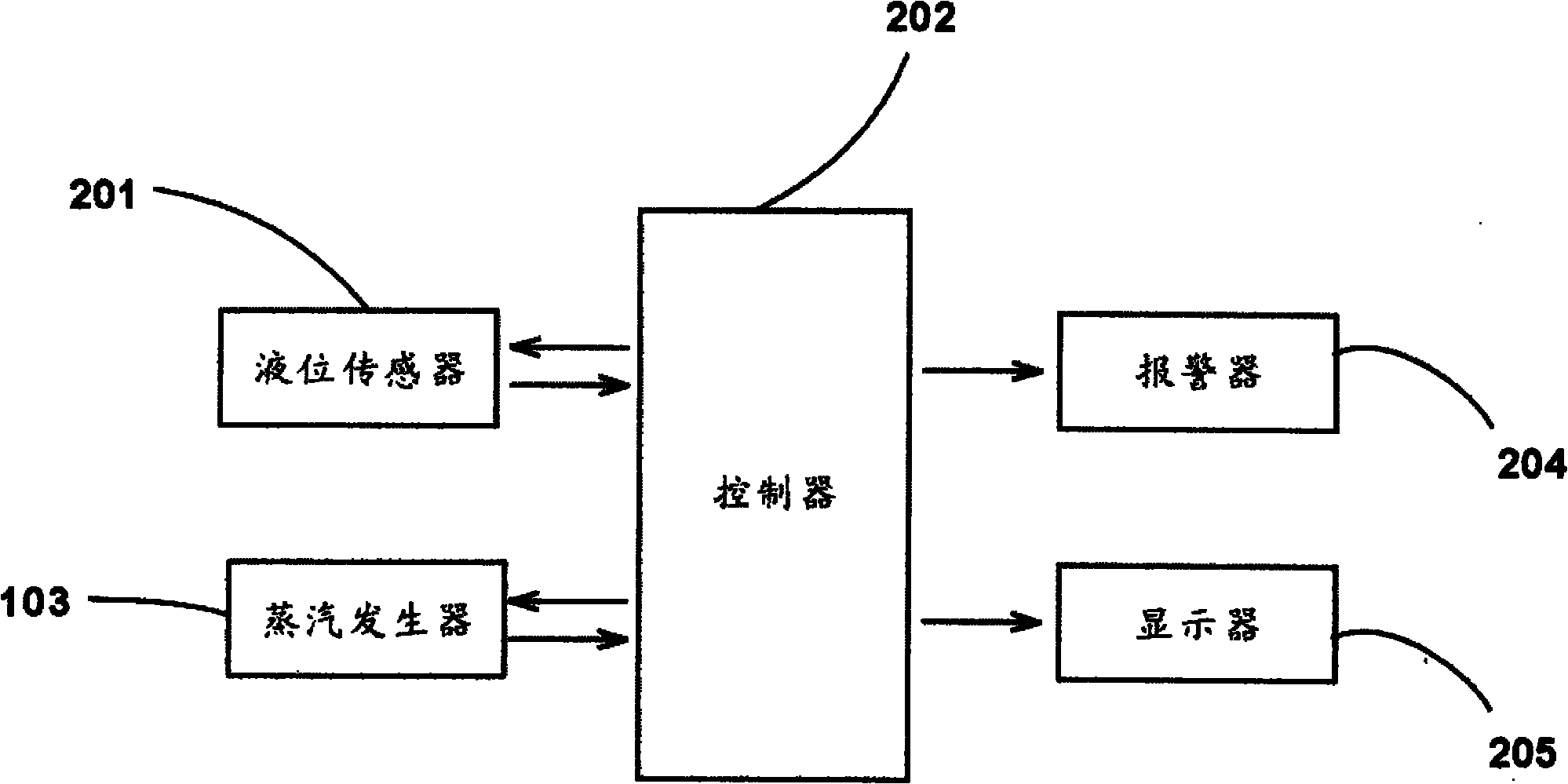

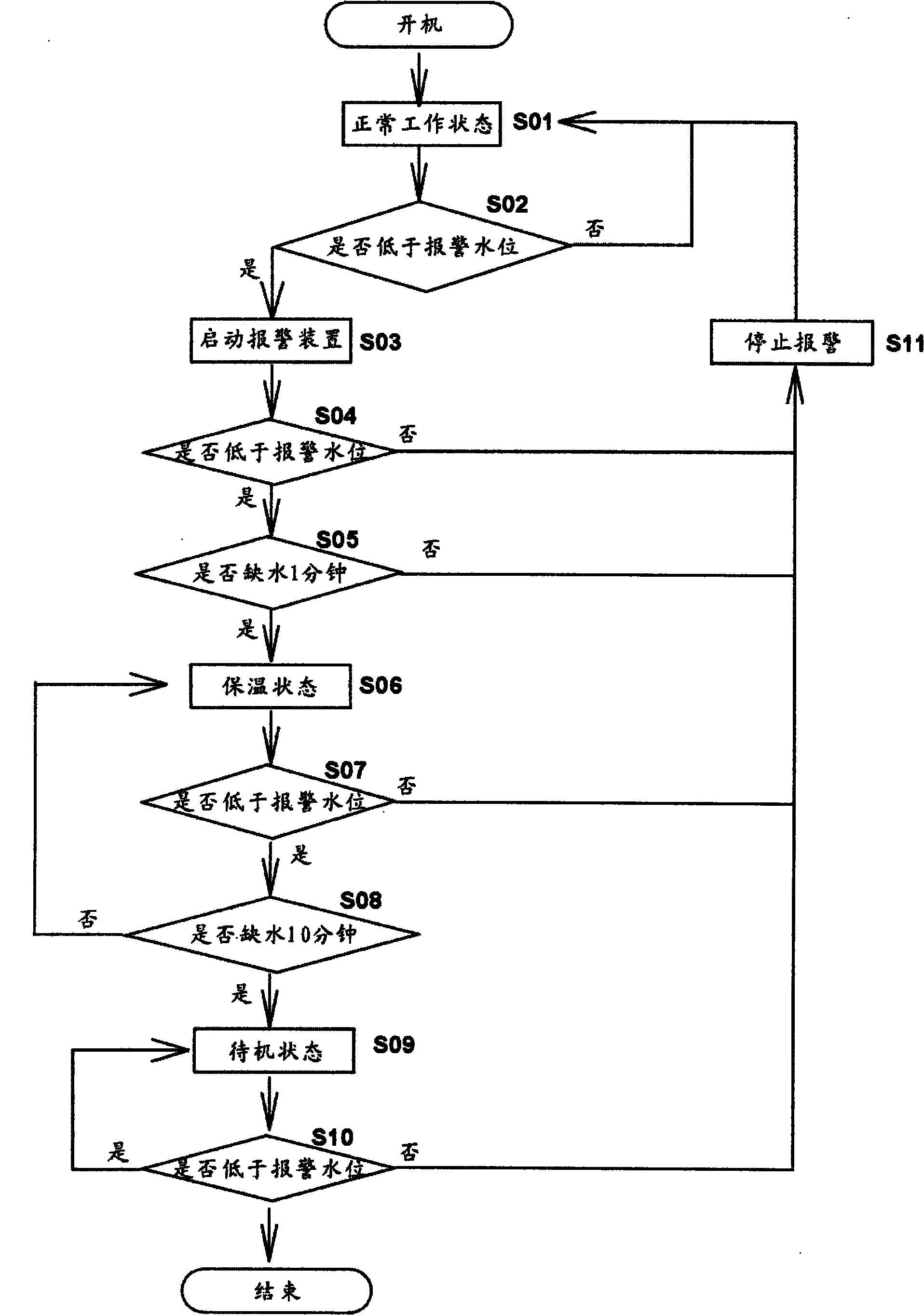

[0029] The water shortage automatic protection device includes a liquid level sensor 201 , a controller 202 and an alarm device 204 . Wherein, the liquid level sensor 201 is installed on the outer wall of the water tank 102, and its specific installation position depends on the minimum water level (i.e. the alarm water level) in the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com