Fork-shaped sheet top locking lock core

A thin piece and fork-shaped technology, which is applied in the field of locking the lock cylinder at the top of the fork-shaped thin piece, can solve the problems of unfavorable anti-theft and poor security, and achieve the effect of increasing the difficulty of unlocking, improving performance and eliminating possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

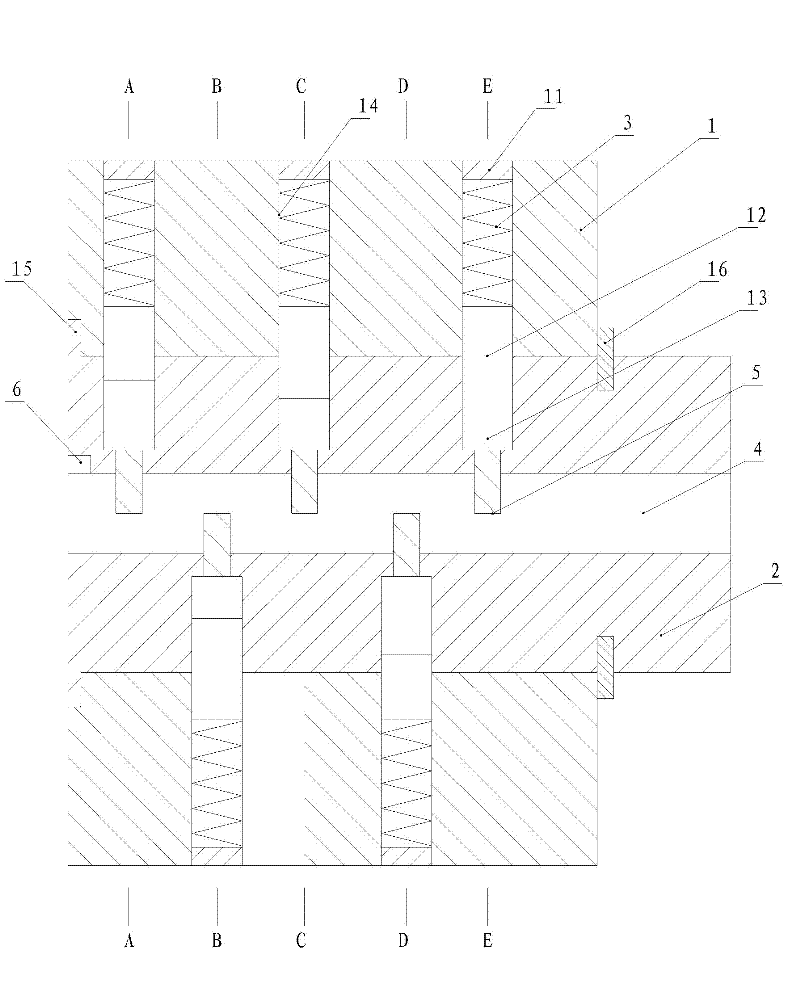

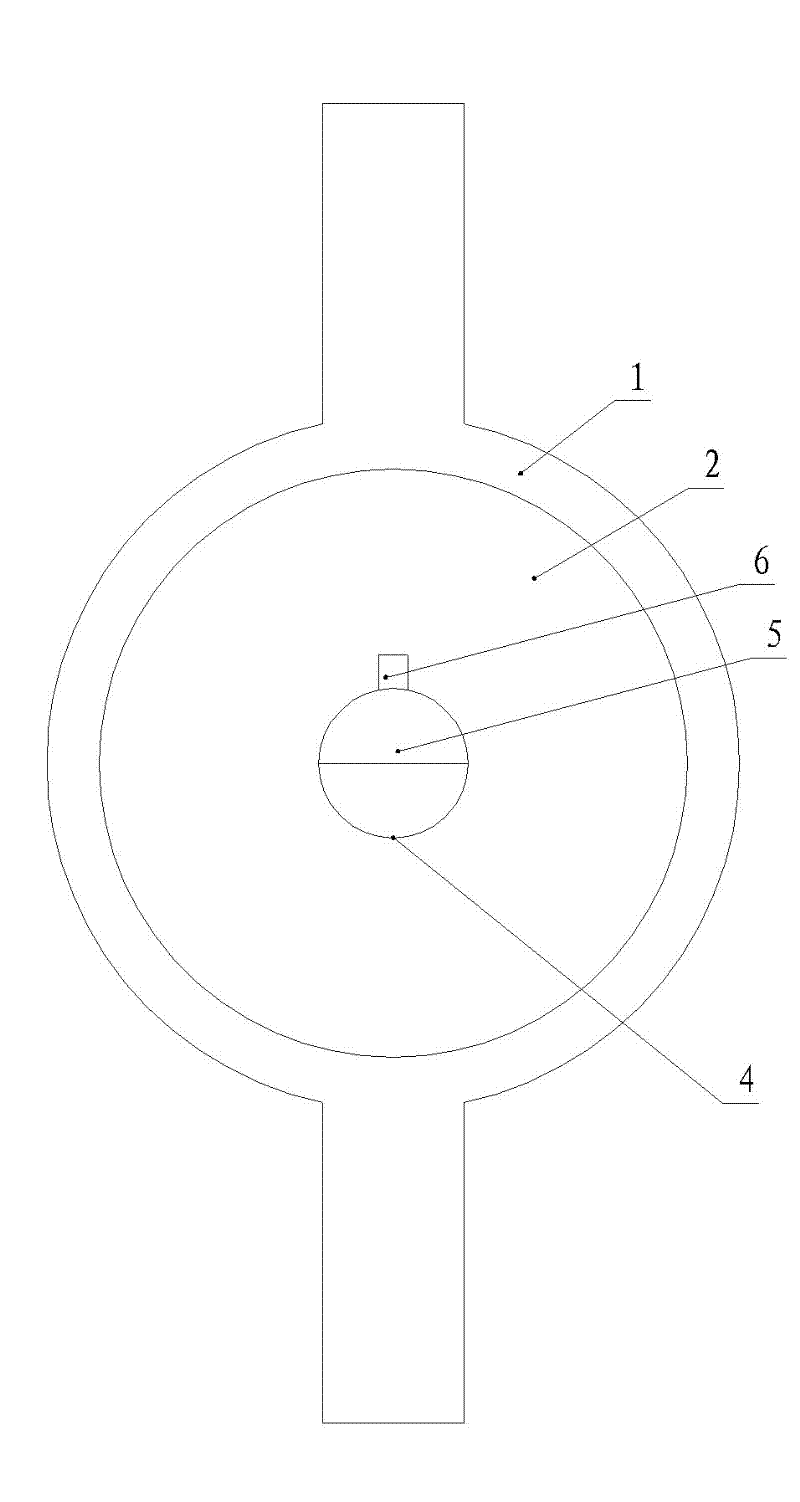

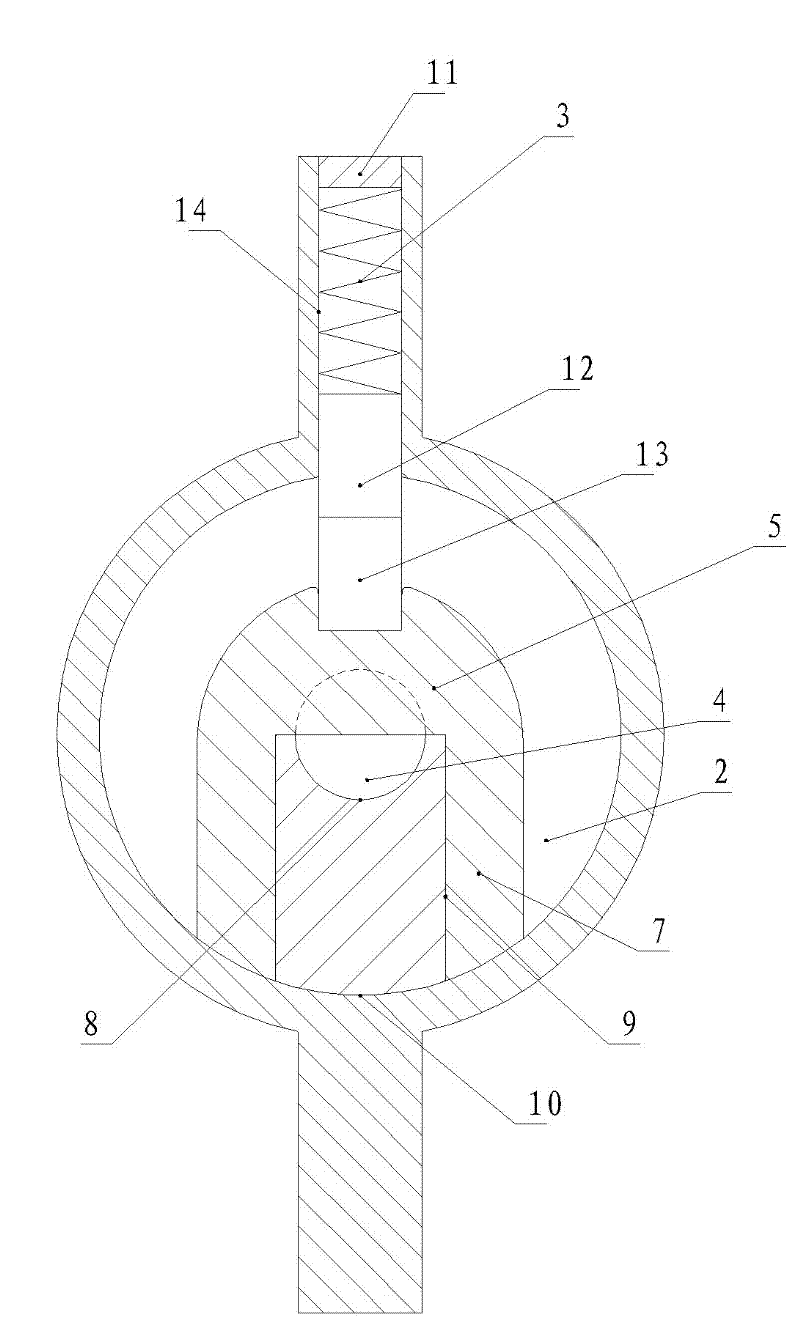

[0035] Embodiment one: see Figure 1-Figure 8 , Figure 16-Figure 18 , a fork-shaped sheet top locking lock cylinder, including a jacket, a cylindrical core, the inside of the jacket is a cylindrical through hole, the core is matched and installed inside the jacket, and the core is provided with an axial cylindrical key hole, the core body is provided with at least a certain number of direction-matched sheet installation gaps; the outer edge of the cross-sectional shape of the core body corresponding to the position of the sheet installation gap is a circular arc, and the middle part of the inner edge is formed by a keyhole. The arc and the two sides are parallel straight sides; a fork-shaped sheet with matching thickness is installed in the installation gap of each sheet. The upper part of the fork-shaped sheet is a beam, and the two sides are vertical legs. The upper beam is placed on the above-mentioned sheet On the inner edge of the core body corresponding to the location...

Embodiment 2

[0043] Embodiment two: see figure 2 , Figure 9-Figure 15 , Figure 16-Figure 18, a fork-shaped sheet top locking lock cylinder, including a jacket, a cylindrical core, the inside of the jacket is a cylindrical through hole, the core is matched and installed inside the jacket, and the core is provided with an axial cylindrical key hole, the core body is provided with at least a certain number of direction-matched sheet installation gaps; the outer edge of the cross-sectional shape of the core body corresponding to the position of the sheet installation gap is a circular arc, and the middle part of the inner edge is formed by a keyhole. The arc and the two sides are parallel straight sides; a fork-shaped sheet with matching thickness is installed in the installation gap of each sheet. The upper part of the fork-shaped sheet is a beam, and the two sides are vertical legs. The upper beam is placed on the above-mentioned sheet On the inner edge of the core body corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com