Equivalent enthalpy drop determination method for two-path mixed feeding low-pressure coal economizer

A low-pressure economizer and a technology to determine the method, which is applied in the direction of feed water heater, preheating, steam generation, etc., can solve the problem of inability to accurately and effectively confirm the thermal efficiency of the low-pressure economizer after the two-way mixing, and the inability to evaluate the optimal operation of the economical power plant And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

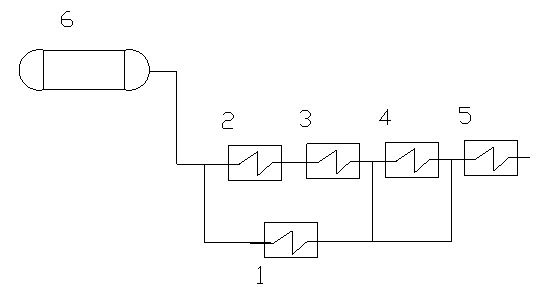

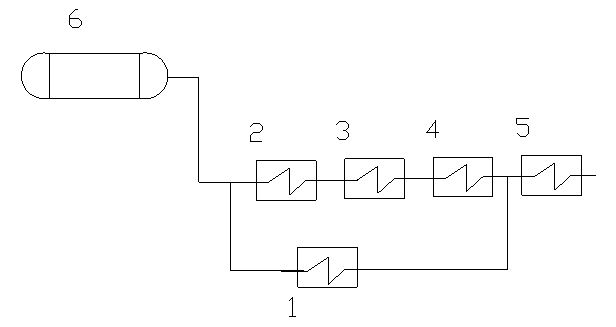

[0047] figure 1 The system diagram of the present invention is given, it connects the same low pressure economizer 1 at the outlet of #7 low plus 4 and the outlet of #8 low plus 5, and then the outlet of low pressure economizer is connected with the outlet of #5 low plus 2 After connecting, connect with deaerator 6 again.

[0048] Method of the present invention is:

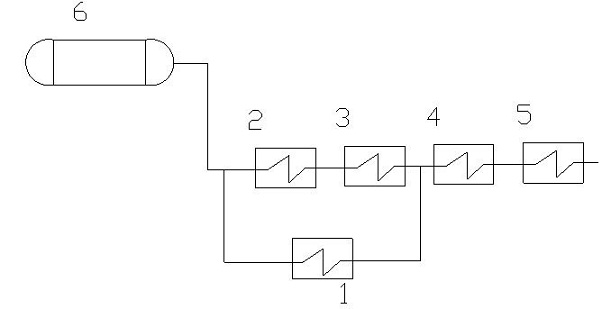

[0049] 1. The #7 low-gas outlet is connected to the low-pressure economizer and connected to the #5 low-gas outlet, such as figure 2 Shown:

[0050] δη 1 =(α d1 *((h d -h 5 )*η 4 +τ 6 *η 6 +τ 5 *η 5 ) / H)*100%

[0051] δη 1 ----- Relative increase percentage of unit thermal efficiency

[0052] alpha d 1 ------ #7 Low feed low pressure economizer flow relative to main steam flow share

[0053] h d -------- Economizer outlet water enthalpy

[0054] h 5 --------#5 Low plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com