Blast furnace coal injection ratio adjusting method and system

A technology of blast furnace coal injection and adjustment method, which is applied in the field of blast furnace smelting and can solve the problems of inaccurate coal injection ratio and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

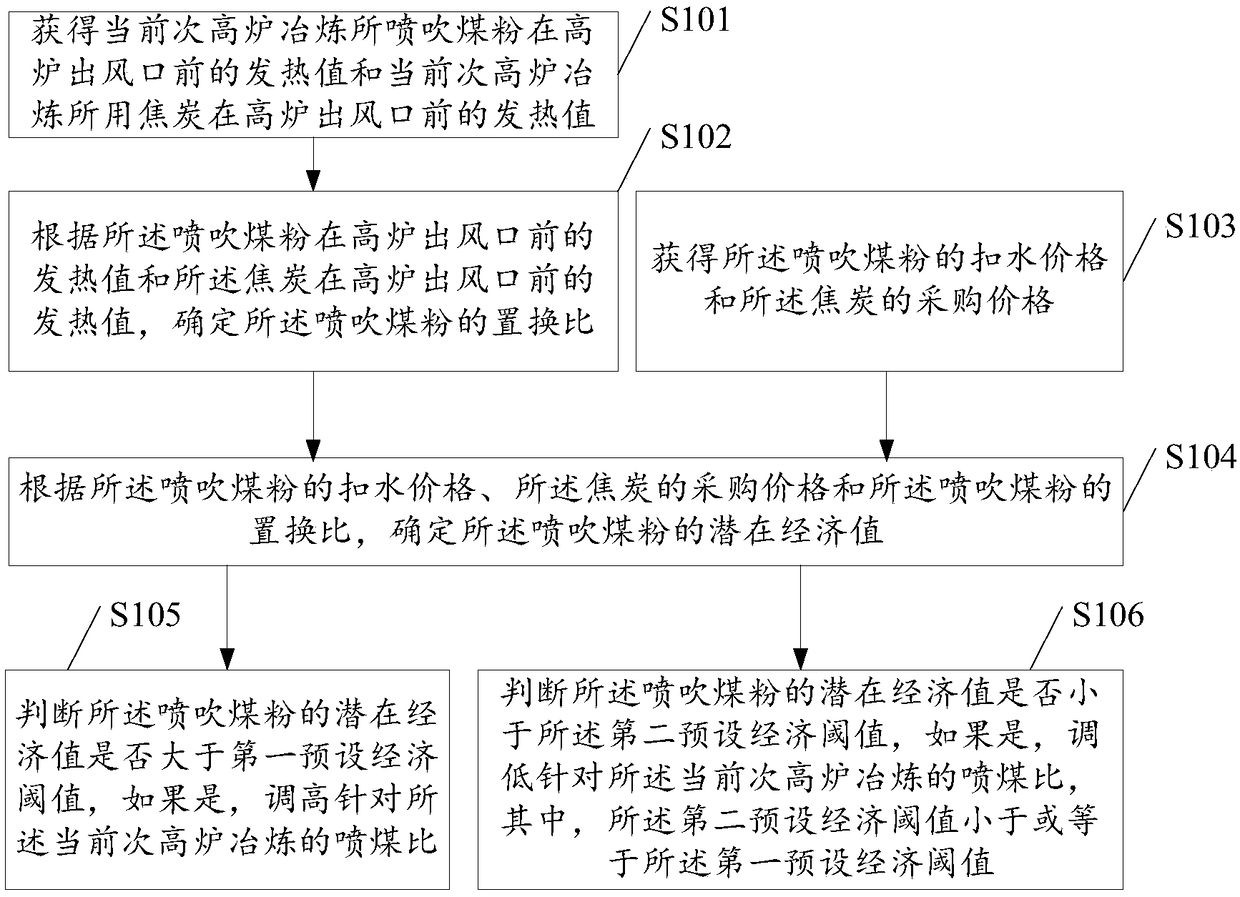

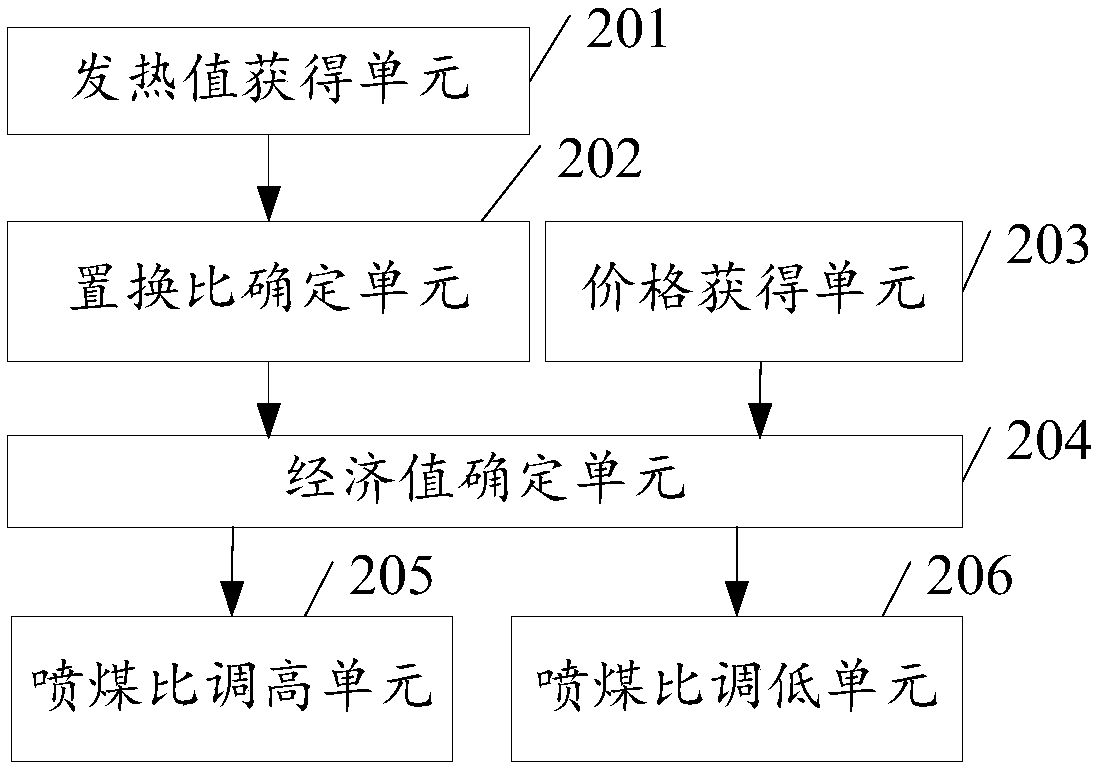

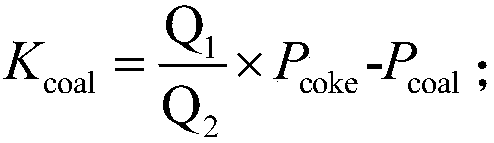

Method used

Image

Examples

Embodiment approach 1

[0117] Embodiment 1: Determine the current coal injection ratio increase corresponding to the potential economic value of the pulverized coal injection based on the first preset linear relationship, wherein the first preset linear relationship is the coal injection ratio increase The amount increases linearly with the increase of the potential economic value; with the increase amount of the current secondary coal injection ratio, the coal injection ratio for the current secondary blast furnace smelting is increased.

Embodiment approach 2

[0118] Embodiment 2: The industrial computer can adjust the coal injection ratio for the current secondary blast furnace smelting at least once until it reaches the preset value of the coal injection ratio.

[0119] Embodiment 3: Calculate the first economic difference between the potential economic value of the pulverized coal injection and the first preset economic threshold; based on the coal injection ratio increase corresponding to the first difference, for the current Sub-blast furnace smelting is carried out to increase the coal injection ratio.

[0120] Specifically, there are multiple height adjustment difference value ranges, and each height adjustment difference value range is in one-to-one correspondence with the coal injection ratio increase, and the first economic difference is determined according to the height adjustment difference value range where the first economic difference value is located. The coal injection ratio corresponding to the value is increased,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com