Cutting method for cutting substrate by utilizing cutting line

A technology of cutting wire cutting and cutting method, which is applied in the field of mechanical processing, and can solve problems such as broken wires, skewed cutting, and steel wire wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a cutting method, which can reduce the use cost of the steel wire in the cutting process, improve the utilization rate of resources, and reduce the processing pressure of the waste cutting wire.

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

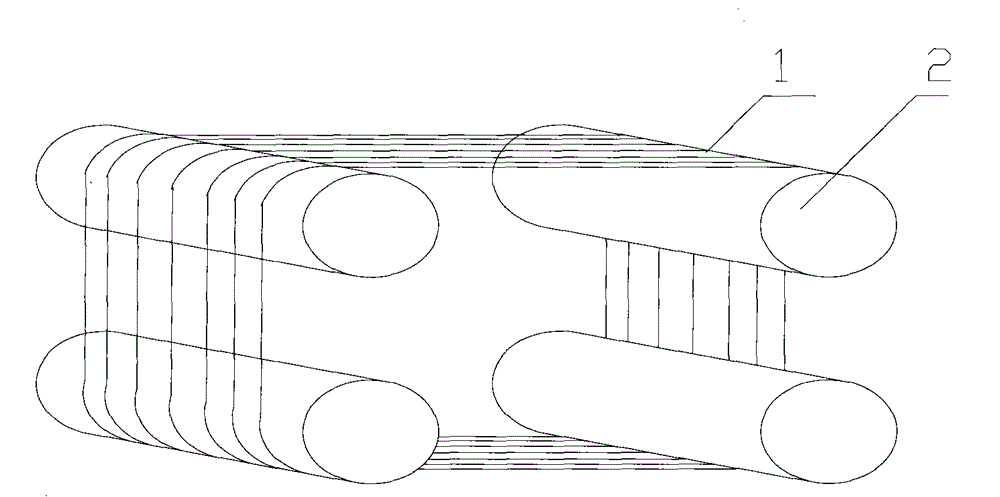

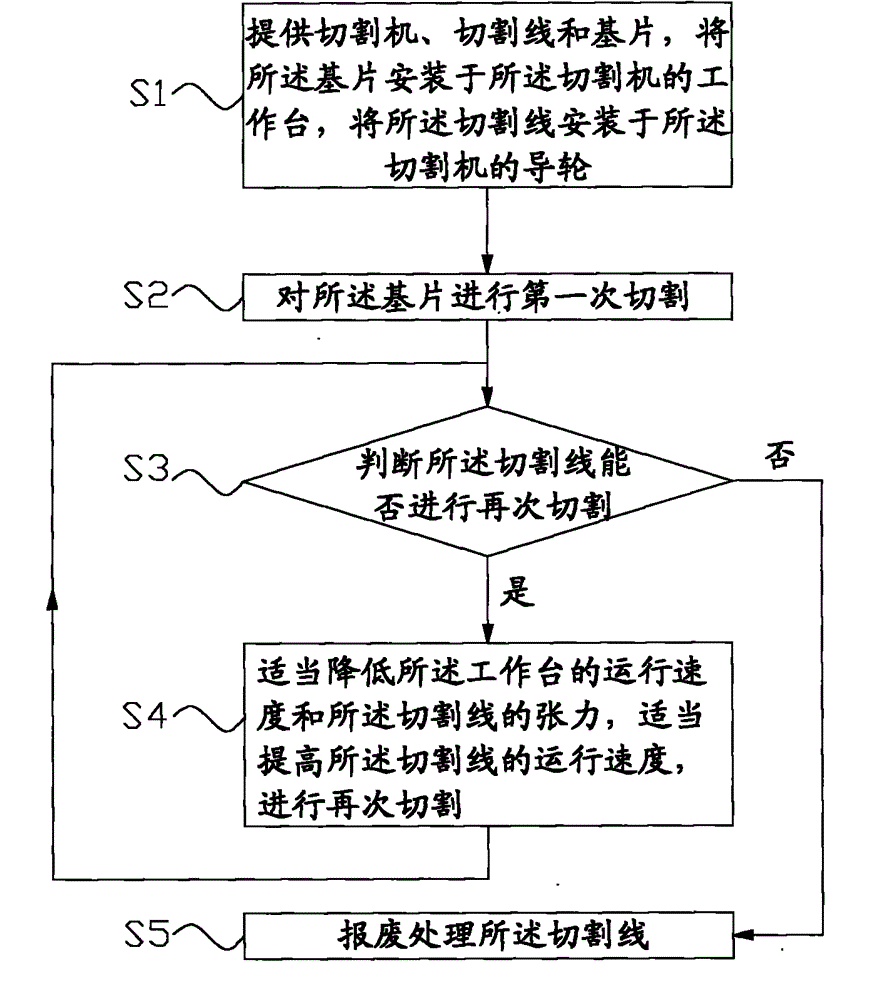

[0027] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the guide wheel part of a typical cutting machine; figure 2 It is a schematic flow chart of the cutting method provided by a specific embodiment of the present invention.

[0028] In a specific embodiment, the cutting method provided by the present invention may specifically include the following steps:

[0029] Step S1: Provide a cutting machine, a cutting wire 1 and a substrate, install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com