Dropping head and special fastening screw driver thereof

A technology of screwdriver and screwdriver head, which is applied to screwdrivers, devices for making medicines into special physical or ingestible forms, manufacturing tools, etc. It can solve problems such as inability to tighten the dripper, poor fastening effect, loose dripper, etc., to achieve Easy to operate, simple in structure, and prevent condensation from clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

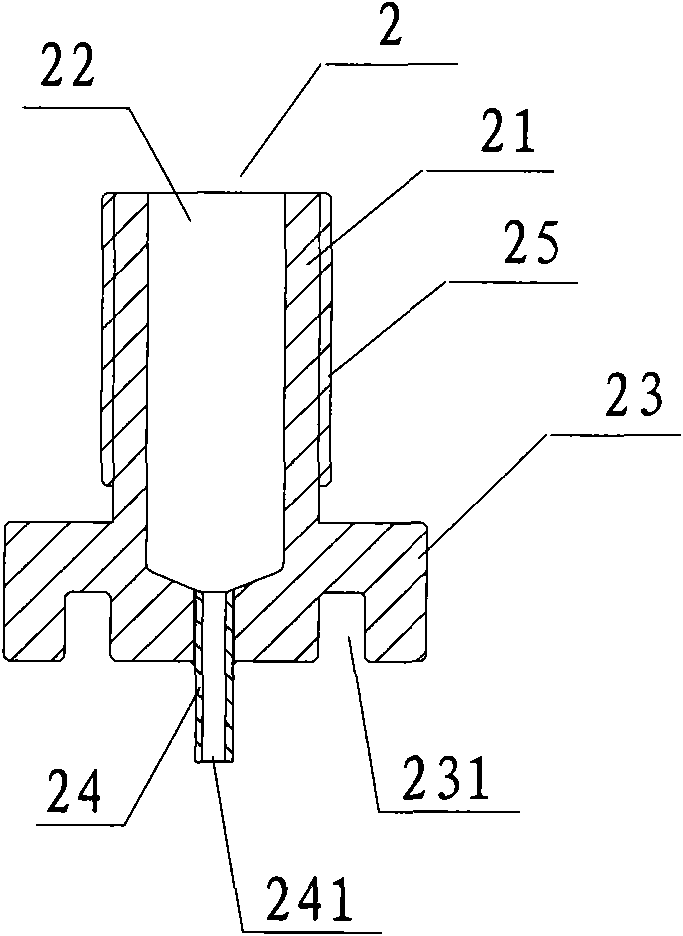

[0018] figure 1 It is a structural schematic diagram of the dripper of the present invention. Such as figure 1 As shown, the present invention provides a dripper 2, including a dripper body 21, a cavity 22 for accommodating liquid material is provided in the dripper body 21, a dripper tray 23 is provided at the end of the dripper body 21, A drip tip 24 protrudes outward from the center of the drip tip tray 23 , and a through hole 241 is opened in the drip tip tray 24 to communicate with the cavity 22 in the drip tip body 21 through the drip tip tray 23 . The drip tip tray 23 is provided with two channels 231, which are arranged on the surface of the drip tip tray 23 in parallel and at intervals. The dripper body 21 is provided with a screw thread 25 for connecting the dripper 2 to a dripper sleeve (not shown in the figure). The distance between the centerlines of the two channels 231 is 5.5-6 mm, and the depth of each channel 231 is 3-4 mm.

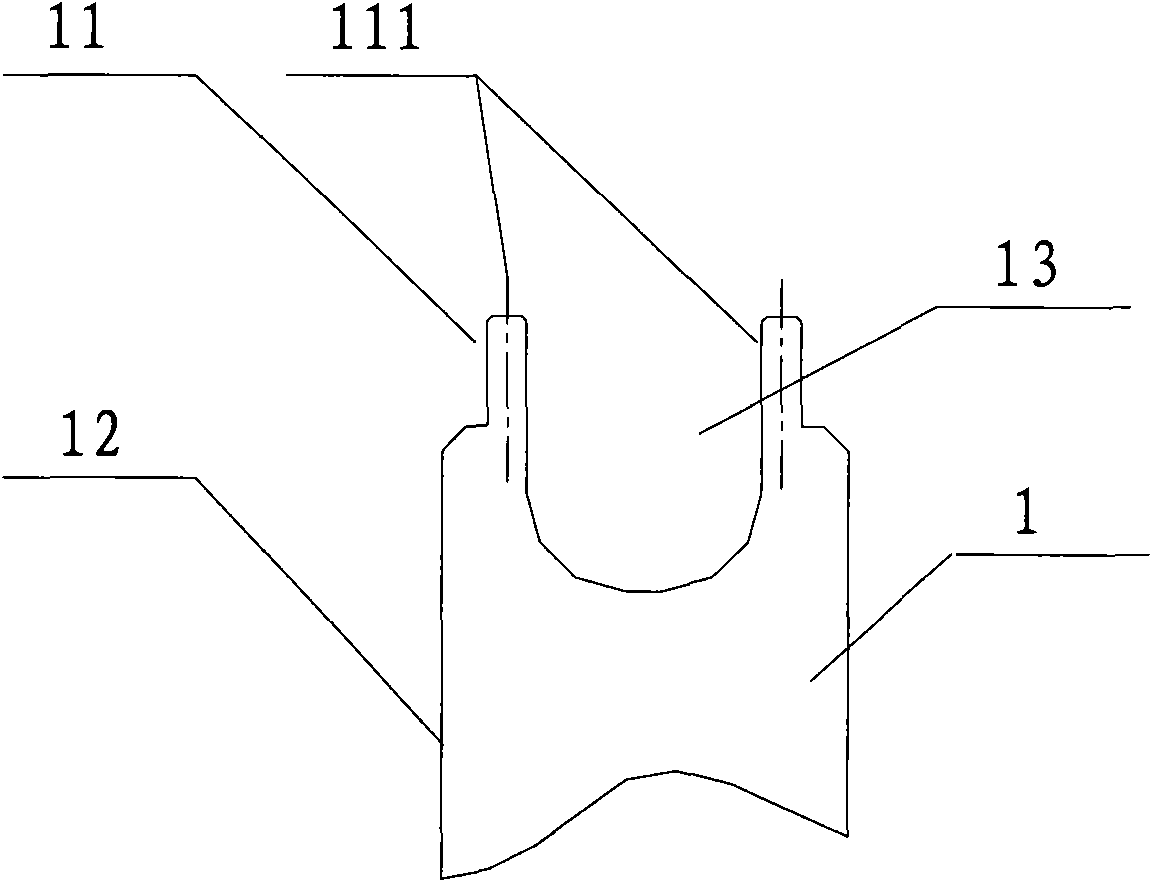

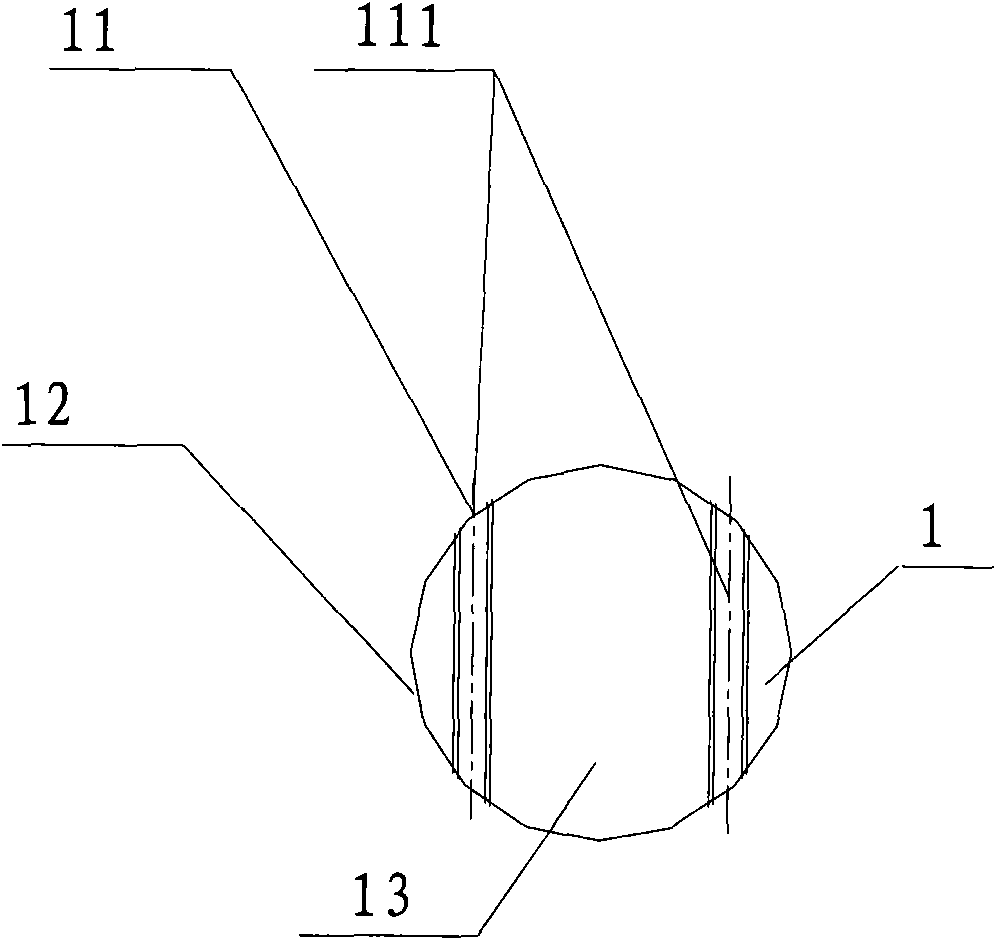

[0019] figure 2 It is the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com