Joint filling sub-machine, joint filling workstation, joint filling system and working method of joint filling system

A caulking sub-machine and working method technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as difficult caulking work, difficult discharge pumping, and bulky volume, etc. To achieve the effect of increasing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

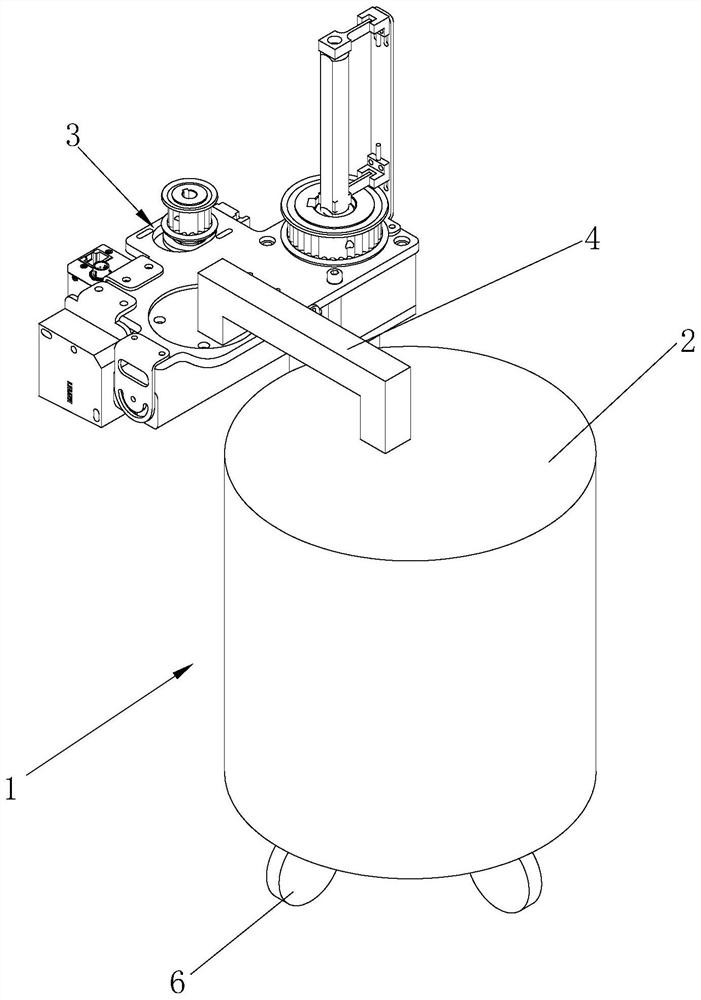

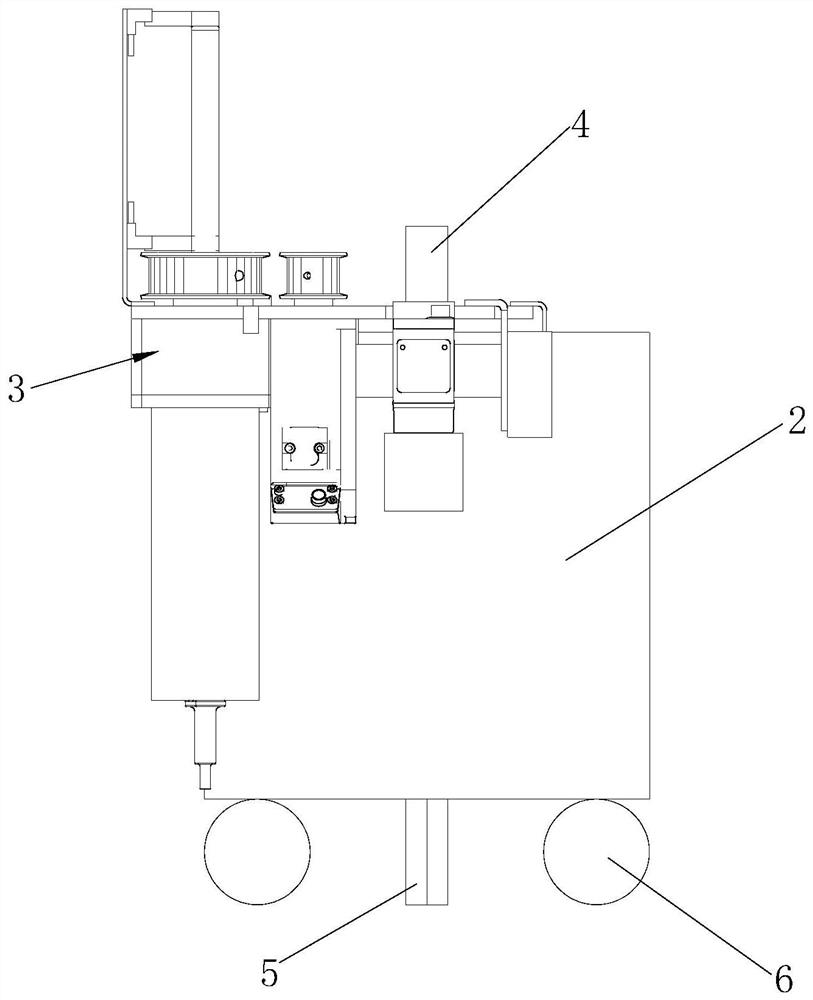

[0063] like Figure 1-Figure 2 As shown, this embodiment provides a sub-machine for caulking 1, which sub-machine 1 includes a storage tank 2, an autonomous walking device and a caulking device 3, wherein the storage tank 2 is used to receive and store the caulking agent, The autonomous walking device can drive the caulking sub-machine 1 to move to the target area, and the caulking device 3 is used to fill the caulking agent in the storage tank 2 into the gap to be filled. The caulking sub-machine 1 provided in this embodiment can repeatedly fill the caulking agent without carrying a caulking agent pumping system. Coverage is wider.

[0064] Further, the self-propelled walking device includes the sub-machine traveling wheels and the sub-machine navigation module. Wherein, the sub-machine walking wheel is used to support the caulking sub-machine 1 and drive the caulking sub-machine 1 to advance, including a steering wheel 5 and a universal wheel 6 arranged at the bottom of the ...

Embodiment 2

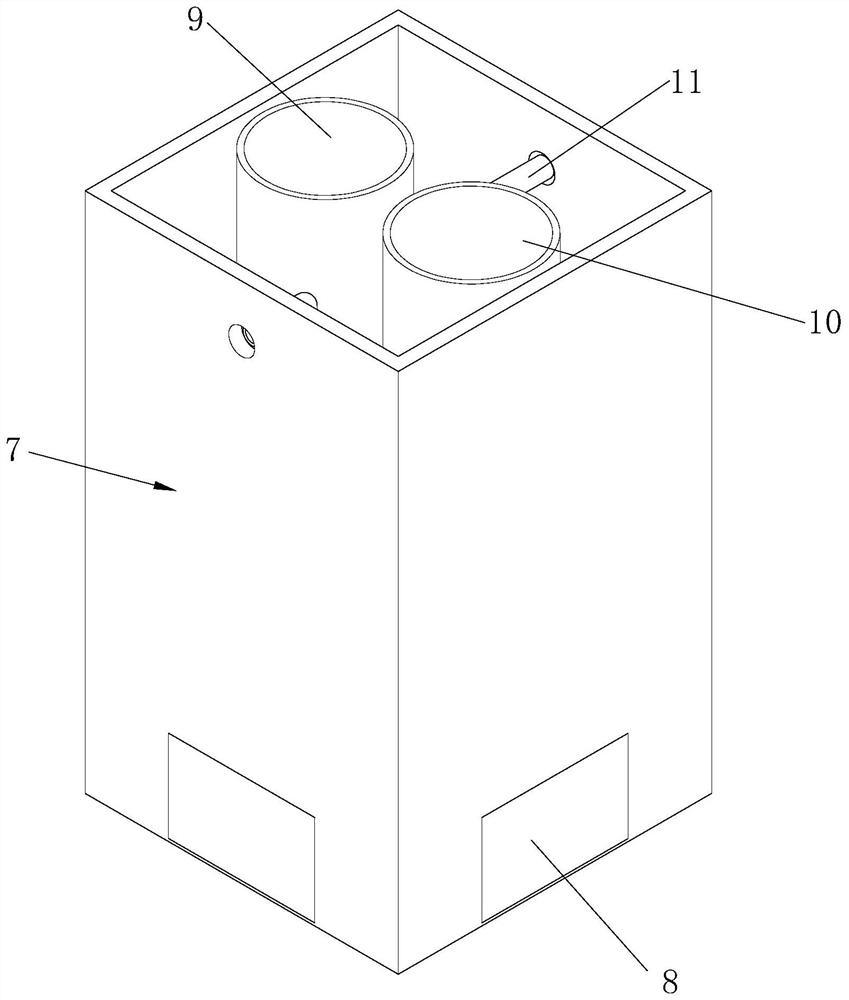

[0070] like Figure 3-Figure 4 As shown, this embodiment provides a caulking workstation 7, which is used in conjunction with the caulking sub-machine 1 provided in Example 1. The caulking workstation 7 includes a sub-machine storage bin 8 and a continuous stirring device 9, wherein the sub-machine storage bin 8 is used to accommodate the caulking sub-machine 1. The caulking agent is placed in the continuous stirring device 9. The continuous agitating device 9 can continuously stir the caulking agent therein, and feed the caulking sub-machine 1 in the sub-machine storage bin 8. Pre-filled with caulk. The caulking workstation 7 can replenish the caulking agent for the sub-machine 1 in time, making the sub-machine 1 smaller and lighter because it does not need to be equipped with a pumping system, so that the sub-machine 1 can work in narrow areas, Improves caulk coverage.

[0071] Specifically, the continuous stirring device 9 includes a stirring arm, a storage tank and a cle...

Embodiment 3

[0079] like Figure 4 As shown, this embodiment provides a caulking system, the caulking system includes the caulking sub-machine 1 provided in the first embodiment and the caulking workstation 7 provided in the second embodiment, the caulking workstation 7 can timely fill The caulking machine 1 is preloaded, cleaned, dried and charged, which is equivalent to transferring the original redundant structure on the caulking machine 1 to the caulking workstation 7, so that the structure of the caulking machine becomes simple, light and convenient. Small and compact, it is convenient for caulking in a narrow space, which greatly improves the coverage of the caulking system, and multiple caulking sub-machines 1 can work at the same time, improving the efficiency of the operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com