On-line replacing method for extrusion roll of fiber spinning traction feeding machine

A squeeze roller and spinning technology, which is applied in the field of online replacement of squeeze rollers in fiber spinning traction and feeding machines, can solve the problems of shortening the running time of spinning equipment, increasing maintenance costs, and tight parking maintenance time, so as to improve spinning The effect of increasing silk production capacity, highlighting substantive features, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

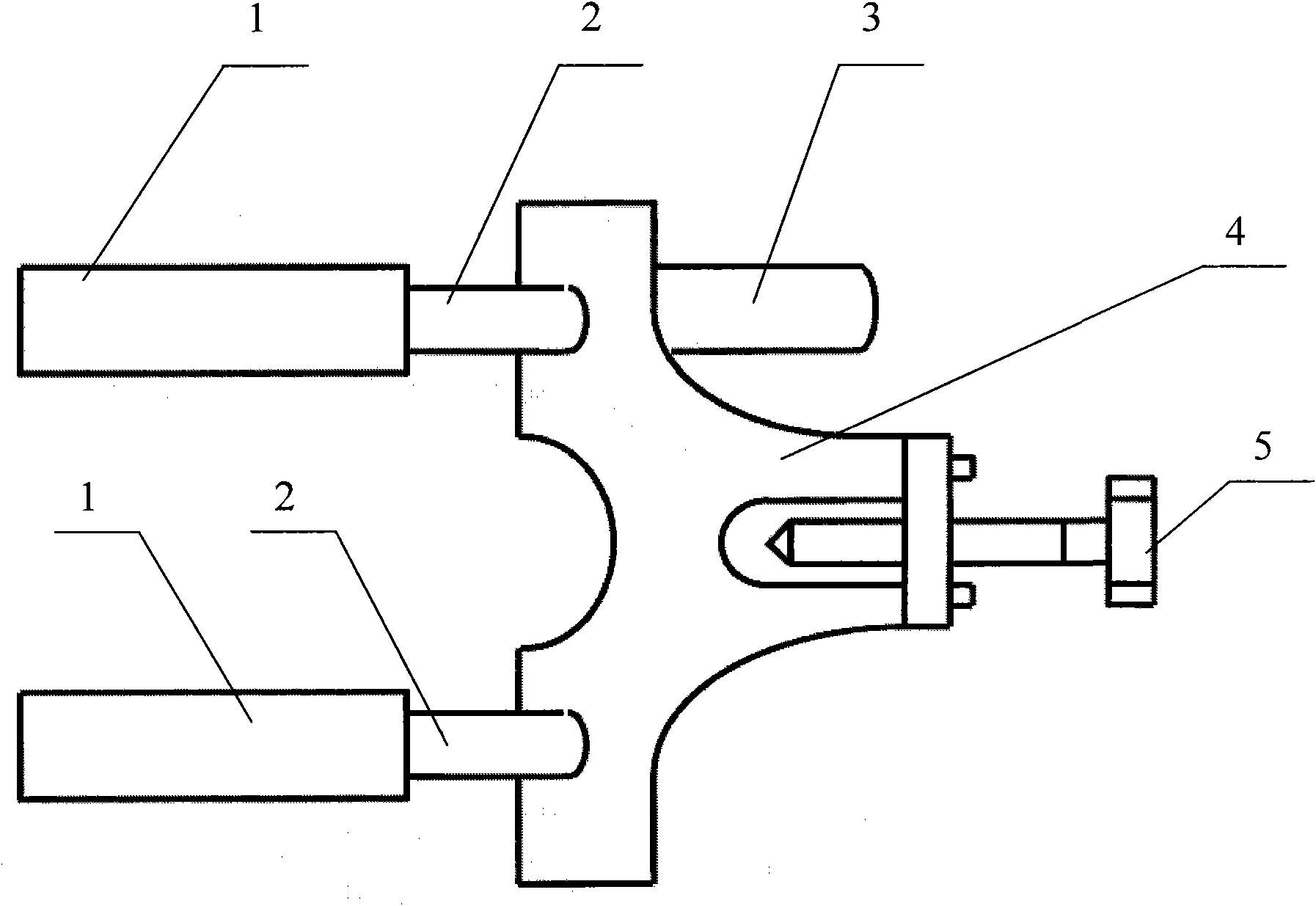

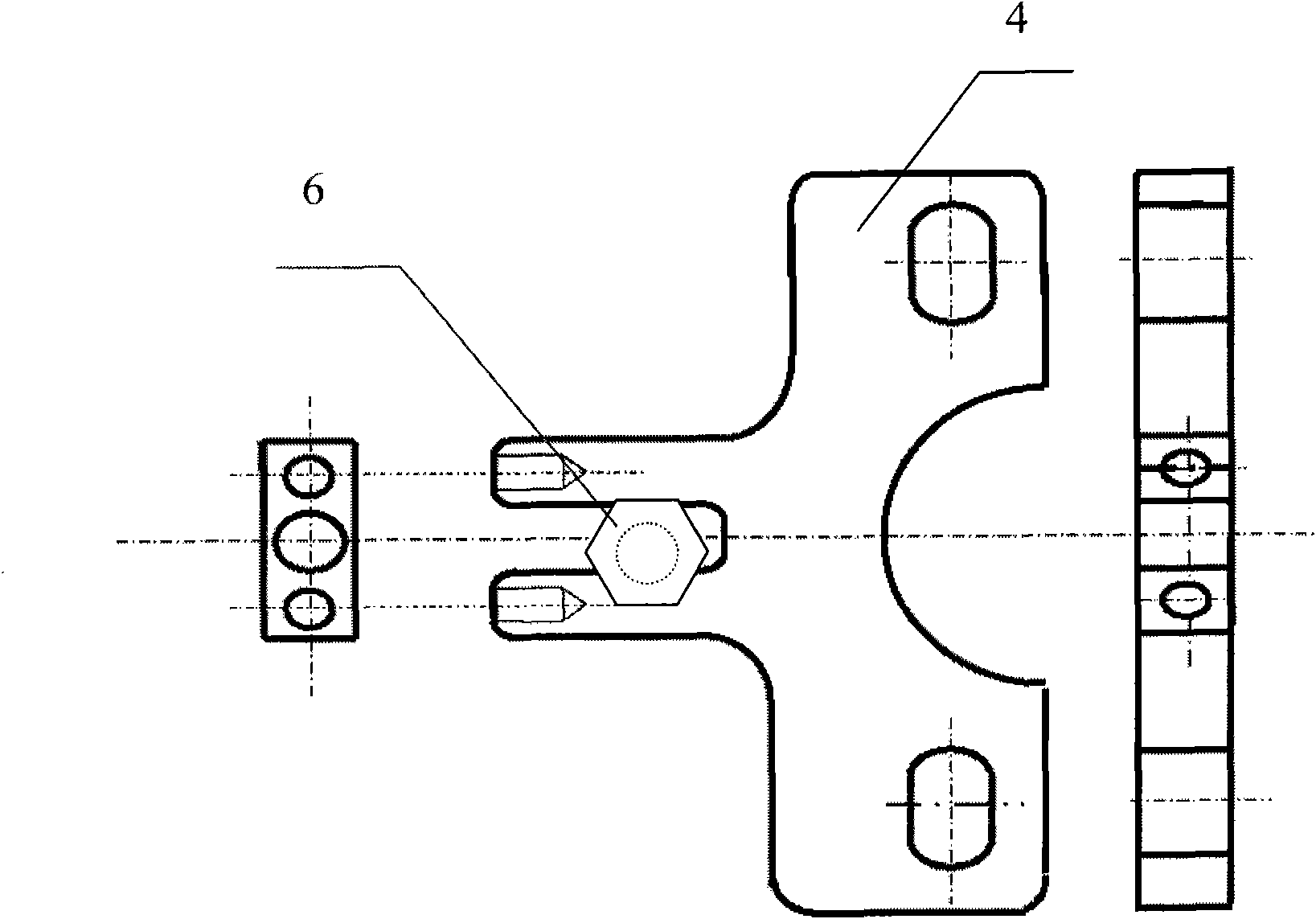

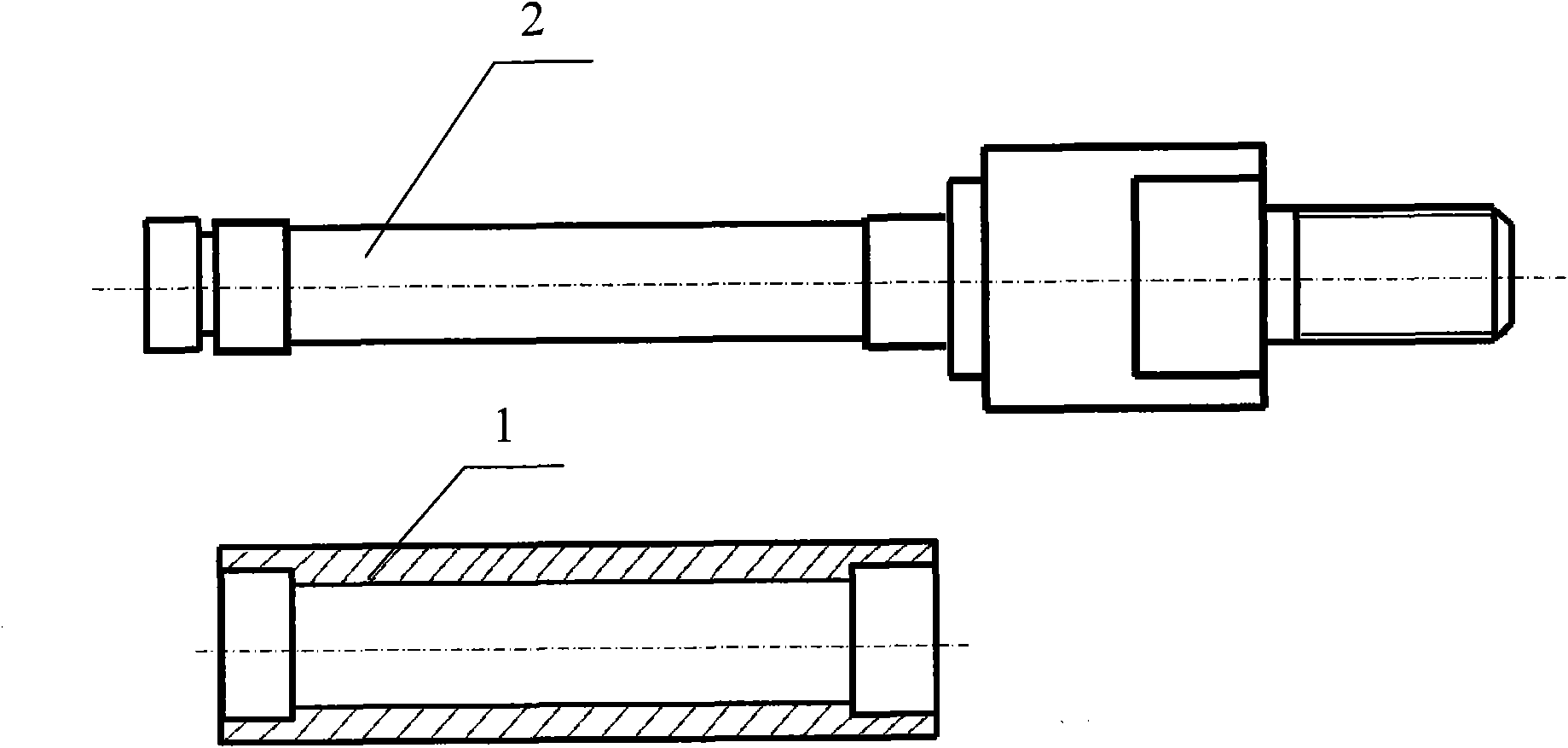

[0032] According to the online replacement method of the extrusion roller of the fiber spinning traction and feeding machine of the present invention, when the extrusion roller breaks down, the extrusion function of the original faulty extrusion roller is temporarily replaced by the special extrusion roller device for maintenance, so as to maintain the fiber spinning The traction-feeding machine device is in normal operation; the maintenance-specific extrusion roller device, through the tray fixing bolt 6, the tray 4 on which the maintenance-specific extrusion roller 1 is fixed passes through the fixing bolt groove in the middle of the tray, and is fixed on the original serial roller shaft seat , complete the operation of replacing the spare squeeze roller online; including the following steps:

[0033] a. Unscrew and take out the middle bolt of the serial roller connecting the faulty extrusion roller;

[0034] b. Through the tray fixing bolt 6, pass the tray 4 fixed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com