Cuter for milling high-quality plate edges and processing method thereof

A quality and milling cutter technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problem of insufficient board edge quality and achieve the effect of board edge smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

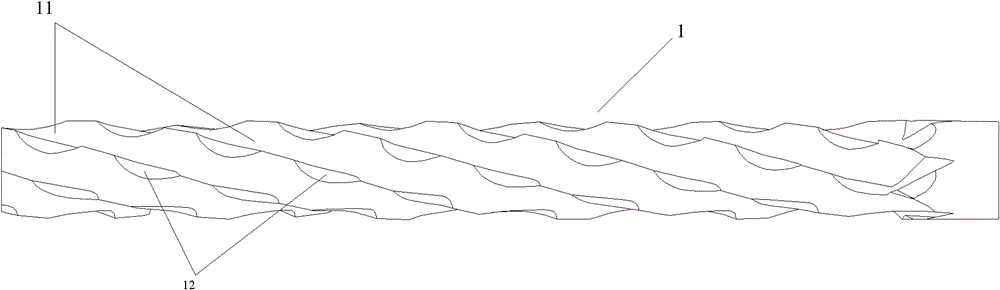

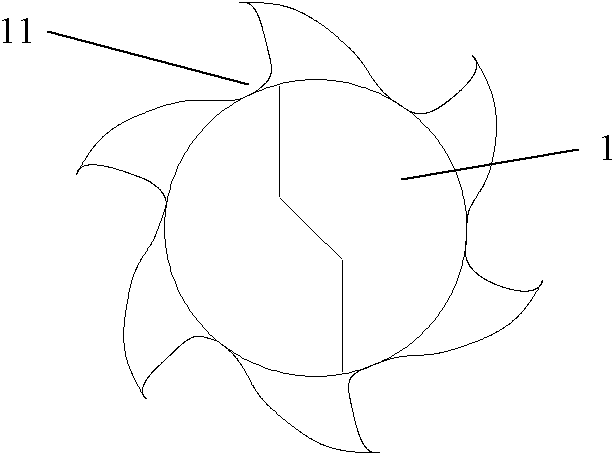

[0037] The structure of the milling cutter is as image 3 and Figure 4 As shown, the cutting groove is a right-handed groove, the tooth-breaking groove is a left-handed groove; the random tooth groove is also a right-handed groove.

[0038] Wherein, the angle of the helix angle of the cutting groove is generally between 15° and 35°, the angle of the helix angle of the broken tooth groove is generally between -15° and -35°, and the helix angle of the random tooth groove The angle can be between 65° and 89°, more precisely, between (the angle of the helix angle of the cutting groove + 45°) ~ 89°, and at the same time, it is necessary to ensure that the angle from the helix angle of the broken tooth groove deviates by 10 ° above. The deviation from the helix angle of the broken tooth groove is to avoid the same trend of the random tooth groove and the broken tooth groove, otherwise the effect of destroying the regular and uniform distribution of the original cutting edge teeth...

Embodiment 2

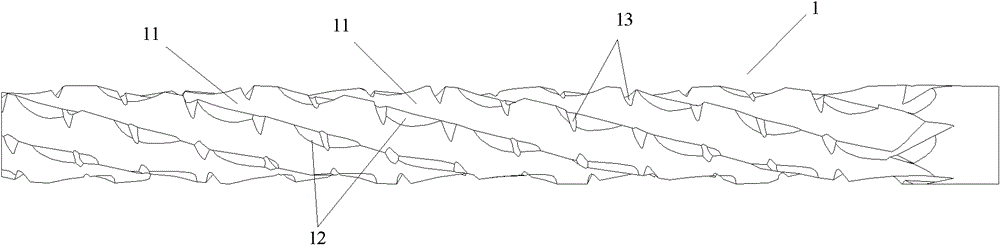

[0041] The structure of the milling cutter is as Figure 5 As shown, the cutting grooves are right-handed grooves, the tooth grooves are left-handed grooves; the random tooth grooves are also left-handed grooves.

[0042] The choice range of the helix angle of the left-handed random tooth groove is larger, and the corresponding design freedom of the number of grooves is also large. Wherein, the angle of the helix angle of the cutting groove is generally between 15° and 35°, the angle of the helix angle of the broken tooth groove is generally between -15° and -35°, and the helix angle of the random tooth groove The angle can be between -15°~-89°, more precisely, between (the angle of the helix angle of the cutting groove -45°)~-89°, and at the same time, it is necessary to ensure that it is consistent with the helix angle of the broken tooth groove The angle deviates by more than 10°. The deviation from the helix angle of the broken tooth groove is to avoid the same trend of ...

Embodiment 3

[0045] The structure of the milling cutter is as Image 6 As shown, the cutting groove is a right-handed groove, the broken tooth groove is a right-handed groove; the random tooth groove is also a right-handed groove.

[0046] Wherein, the angle of the helix angle of the cutting groove can generally be between 15° and 35°, and the angle of the helix angle of the broken tooth groove can generally be between (the angle of the helix angle of the cutting groove+45°)~89°, The angle of the helix angle of the random tooth groove can be between 65° and 89°, more precisely, between (the angle of the helix angle of the cutting groove + 45°) ~ 89°, and at the same time, it is necessary to ensure that it is consistent with the broken tooth groove The angle of the helix angle deviates by more than 10°. The deviation from the helix angle of the broken tooth groove is to avoid the same trend of the random tooth groove and the broken tooth groove, otherwise the effect of destroying the regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com