Mounting device of single-needle quilter shuttle peg

An installation device and quilting machine technology, applied in the field of quilting machines, can solve problems such as inconvenient installation and disassembly, long time, and easily damaged components, and achieve the effects of reducing the frequency of bobbin replacement, improving utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

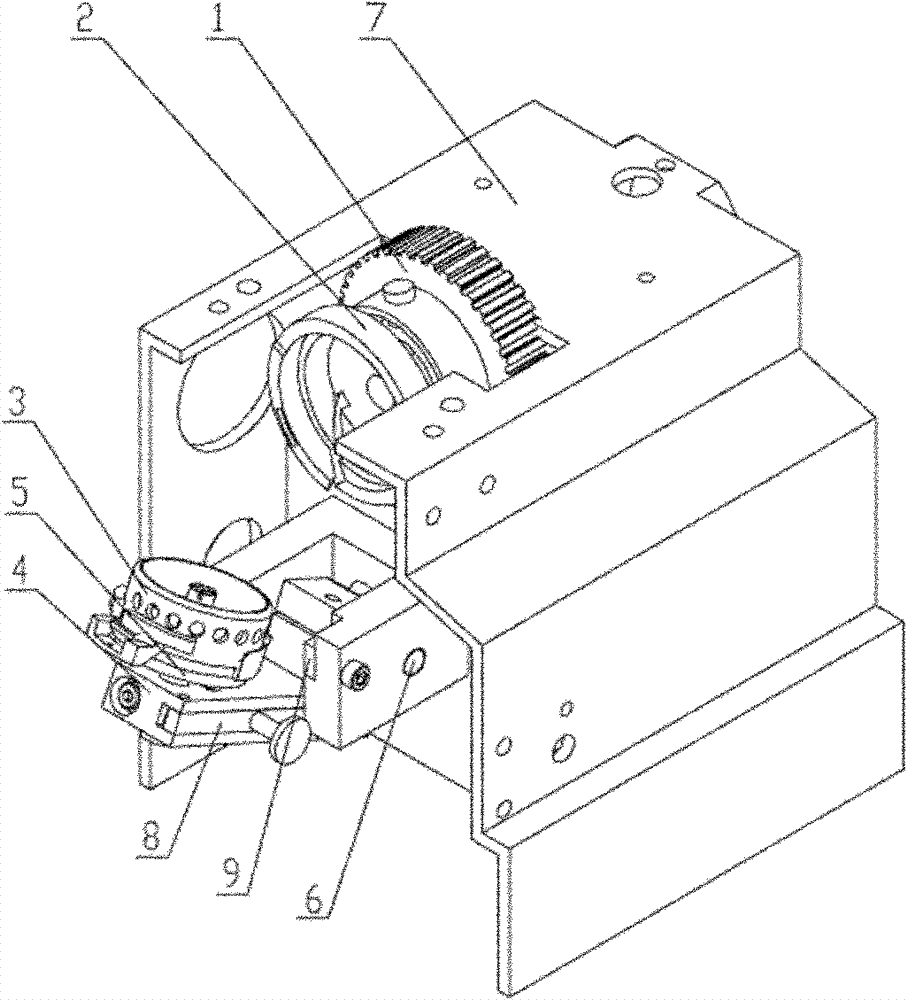

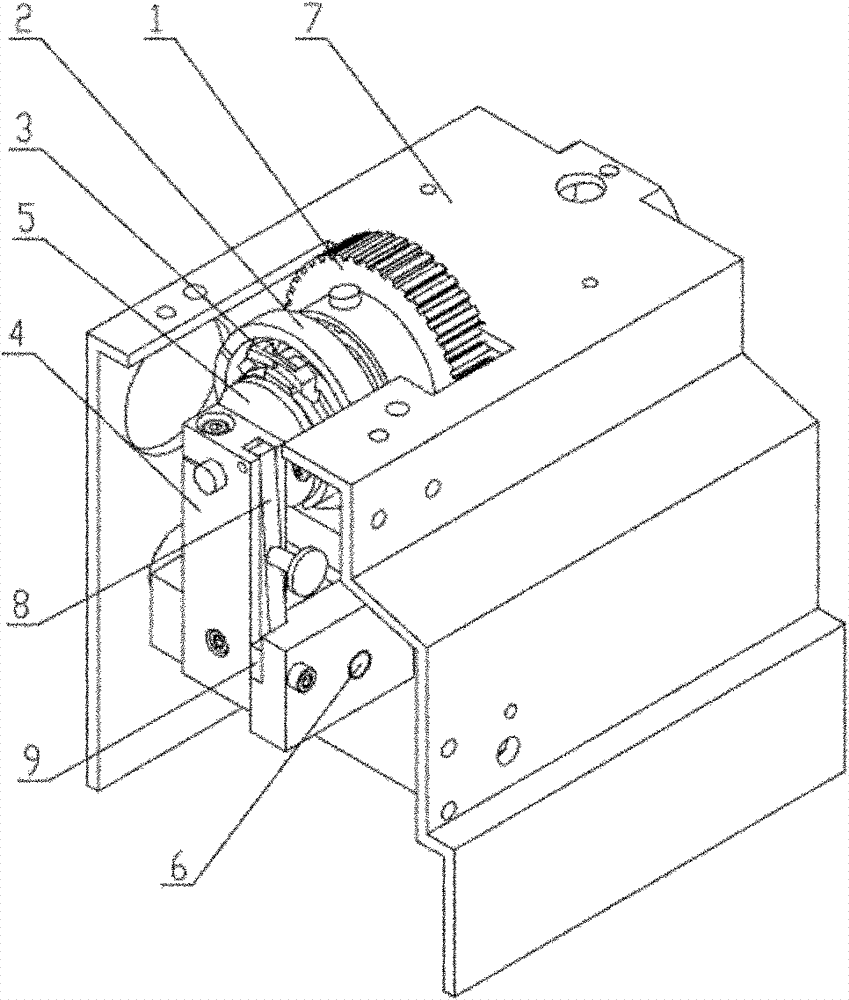

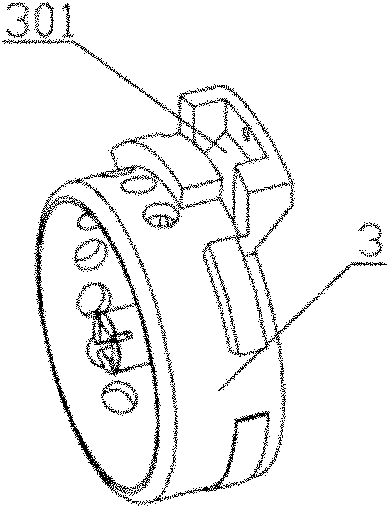

[0016] Such as figure 1 As shown, a device for installing the bobbin of a single needle quilting machine includes a synchronous gear 1 and a rotary hook 2 that are synchronously rotatingly installed on the frame 7 to accommodate the bobbin (common parts, omitted in the figure) The bobbin case 3 in the inner cavity of the rotary hook 2 can be installed and disassembled. A swing seat 4 is provided. One end of the swing seat 4 is provided with a mounting seat 5 facing the rotary hook 2, and the top of the mounting seat 5 is provided with a protruding clasp 501, and a buckle is provided at the top of the corresponding bobbin case 3. Enter the buckle groove 301 of the buckle tooth 501, when installing the bobbin case 3, align the buckle groove 301 of the bobbin case 3 with the buckle tooth 501 of the mounting seat 5, and install the bobbin case 3 through the buckle of the buckle groove 301 and the buckle tooth 501 On the mounting seat 5; the other end is pivotally connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com