Sand control sieve tube

A sand control screen and sand control technology, which is applied in the field of filter screen or liner, can solve the problems of incompetence, sand control strength and validity period limitation, etc., and achieve the effect of strong adaptability and good sand control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

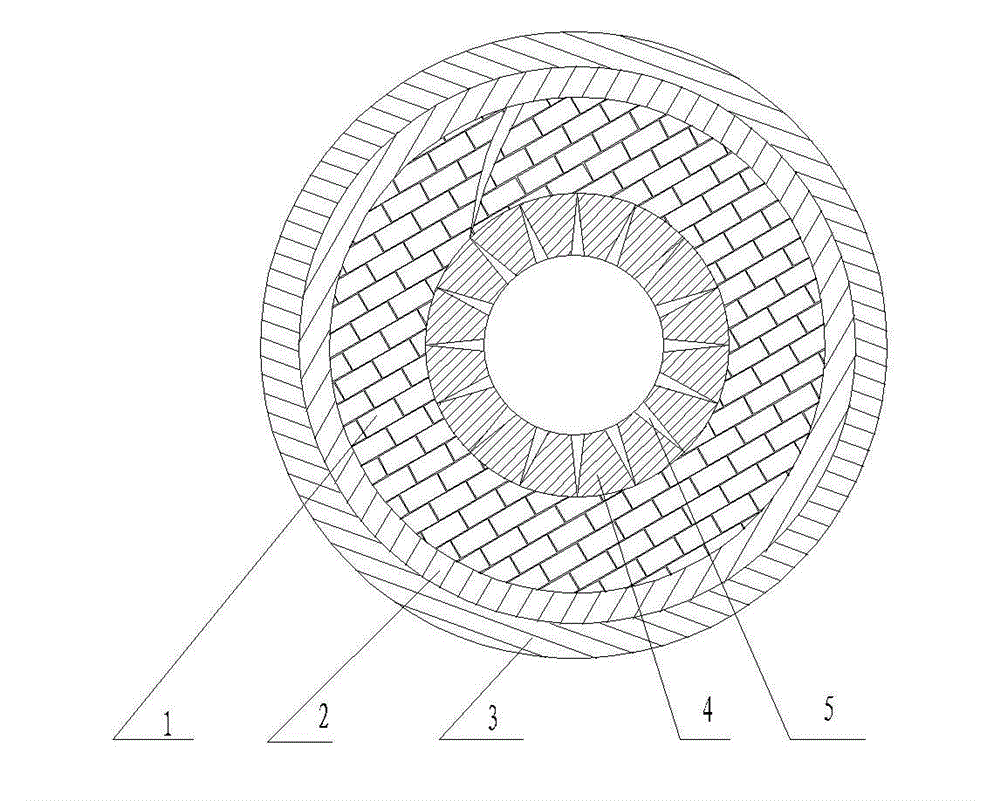

[0012] Such as figure 1 As shown, the sand control screen of the present invention is composed of a multi-layer tubular structure.

[0013] The outermost layer is the protective shell layer 3. Its function is to protect the inner structure of the sand control screen from damage during transportation and construction; Take off, play the role of equalizing expansion force.

[0014] The part inside the protective shell layer 3 is the roll-out expandable sand control screen layer 2, which can expand and expand outward under the pushing action of the gravel packing layer 1, and initially filter the crude oil to form a primary sand-retaining barrier; at the same time , to block the expansion of the gravel in the screen tube, and initially filter the crude oil to form a primary sand-retaining barrier; at the same time, prevent the leakage of the gravel from the pores of the protective shell during the expansion of the screen tube.

[0015] The middle part is the gravel packing laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com