Device for automatically marking additional external axis robot based on laser tracking measurement and method thereof

A technology of laser tracking measurement and automatic calibration, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of insufficient system and comprehensiveness, difficult processing, and no numerical indicators of accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

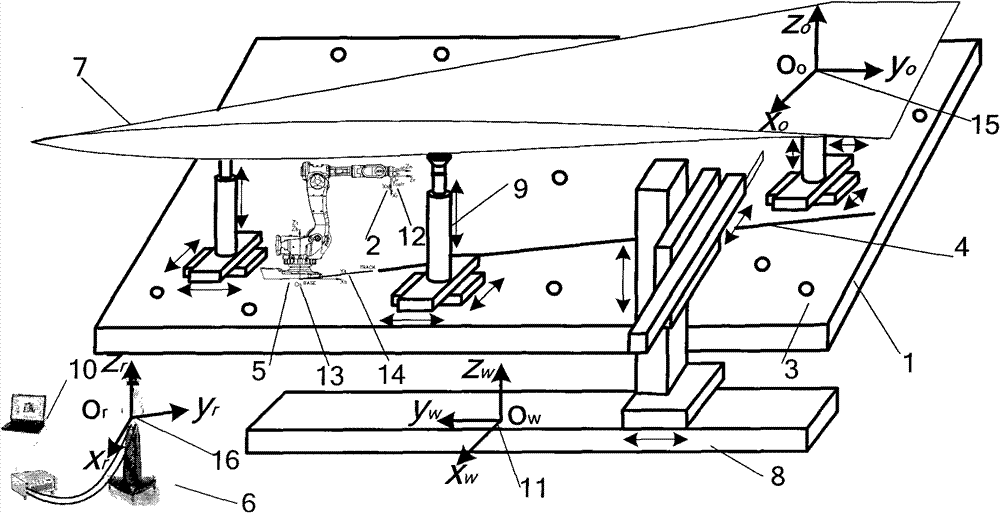

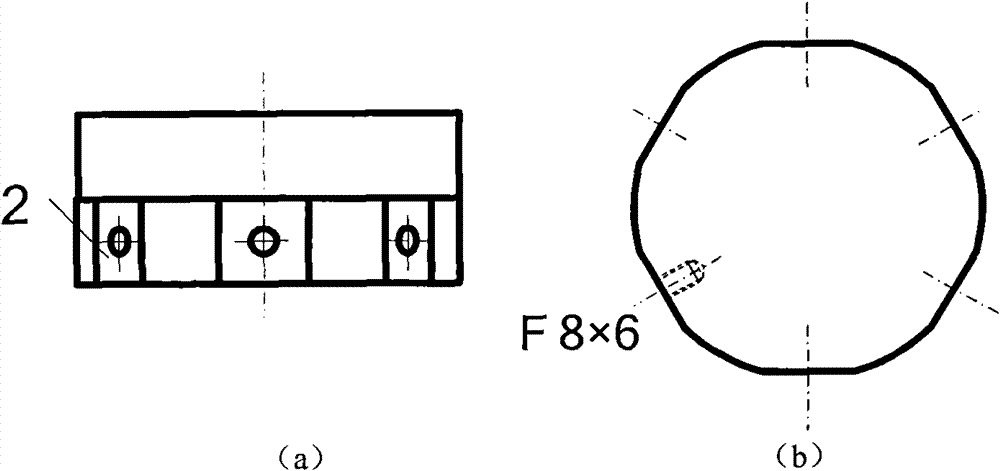

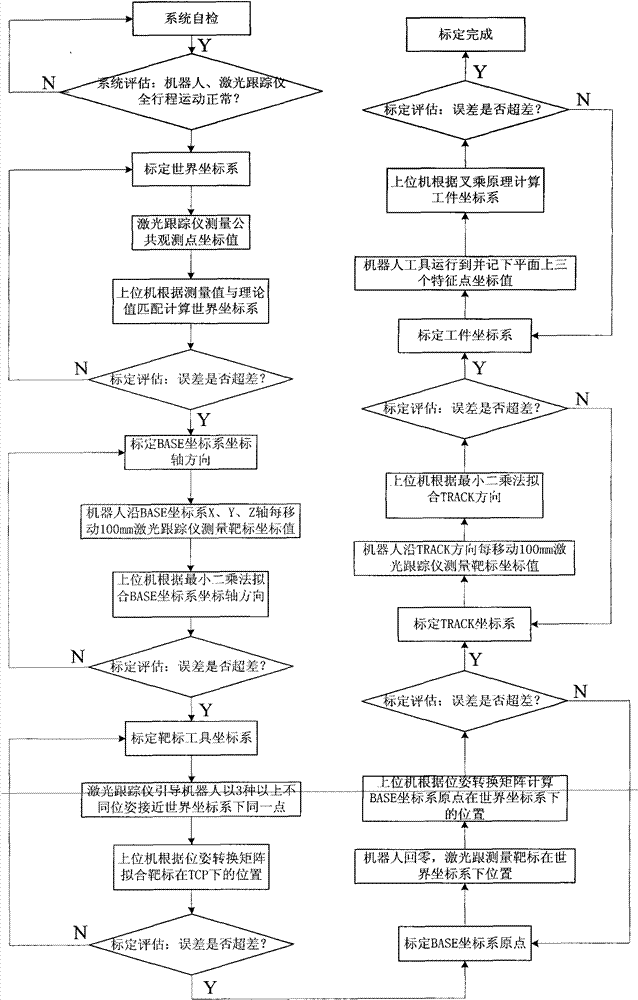

[0080] Such as figure 1 As shown, the automatic calibration device for an additional external axis robot based on laser tracking measurement includes a system platform 1, a target flange 2, a target mounting hole 3, a robot guide rail 4, a robot 5, a laser tracker 6, a workpiece 7, and a CNC finishing machine tool 8 , three-coordinate numerical control positioner 9, upper computer 10; system platform 1 is equipped with 9 target installation holes processed by high-precision numerical control machine tool 3, three-coordinate numerical control positioner 9, robot guide rail 4, on the three-coordinate numerical control positioner The workpiece 7 is fixed on the 9, the robot 5 is installed on the robot guide rail 4, the target flange 2 is installed on the robot 5, there are 6 target mounting holes 3 on the target flange 2, and a target is arranged on the target mounting hole 3, The outside of the system platform 1 is equipped with a CNC finishing machine tool 8 , a laser tracker 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com