A Method for Field Calibration of Ground Hydraulic Tester

A hydraulic tester and field calibration technology, applied in testing/calibration devices, instruments, measuring fluid pressure, etc., can solve the problem of hydraulic tester equipment accuracy, air tightness, airtightness reduction, hydraulic tester oil leakage, flowmeter Accuracy reduction and other problems, to achieve the effect of low cost, accurate and reliable value, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The steps of the calibration method involved in the present invention are:

[0030] Step 1: Selection of Calibration Equipment

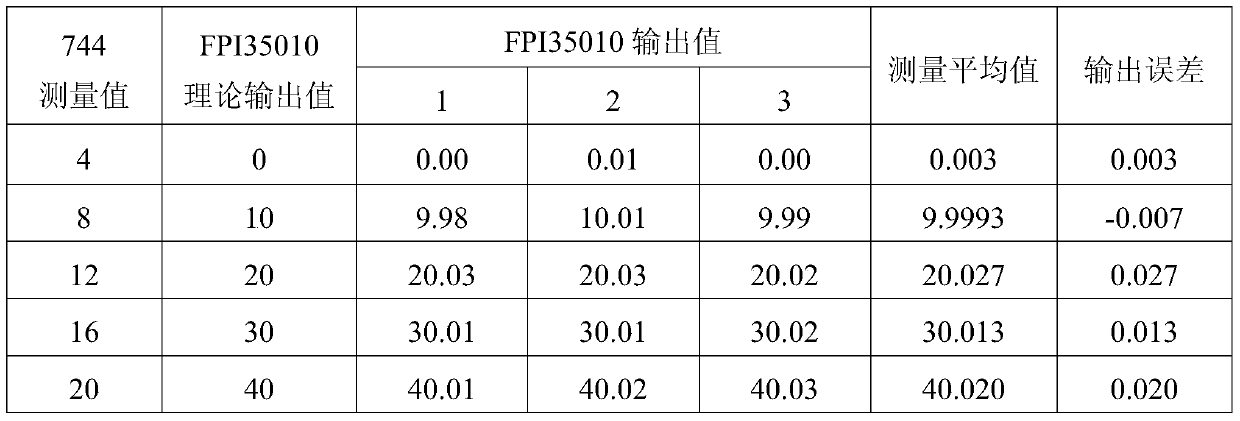

[0031] The calibrator number is 744; the parameters are: current gear measurement range: (0~22) mA; measurement allowable error: 0.01%+0.005%.

[0032] Step 2: Calibration Preparation

[0033] Step 2.1: Power on and warm up

[0034] As the standard calibrator and the large-scale equipment where the digital display meter to be calibrated is normally connected to 220V, 50Hz mains power. Warm up for 15 minutes after starting up.

[0035] Step 2.2: Reference Signal Input

[0036] After power-on, according to the use requirements of the digital display meter FPI35010 to be calibrated, use the power supply of the experiment / work site to provide a stable reference signal of 4-20mA for the digital display meter FPI35010 to be calibrated.

[0037] Step 2.3: Device Connection

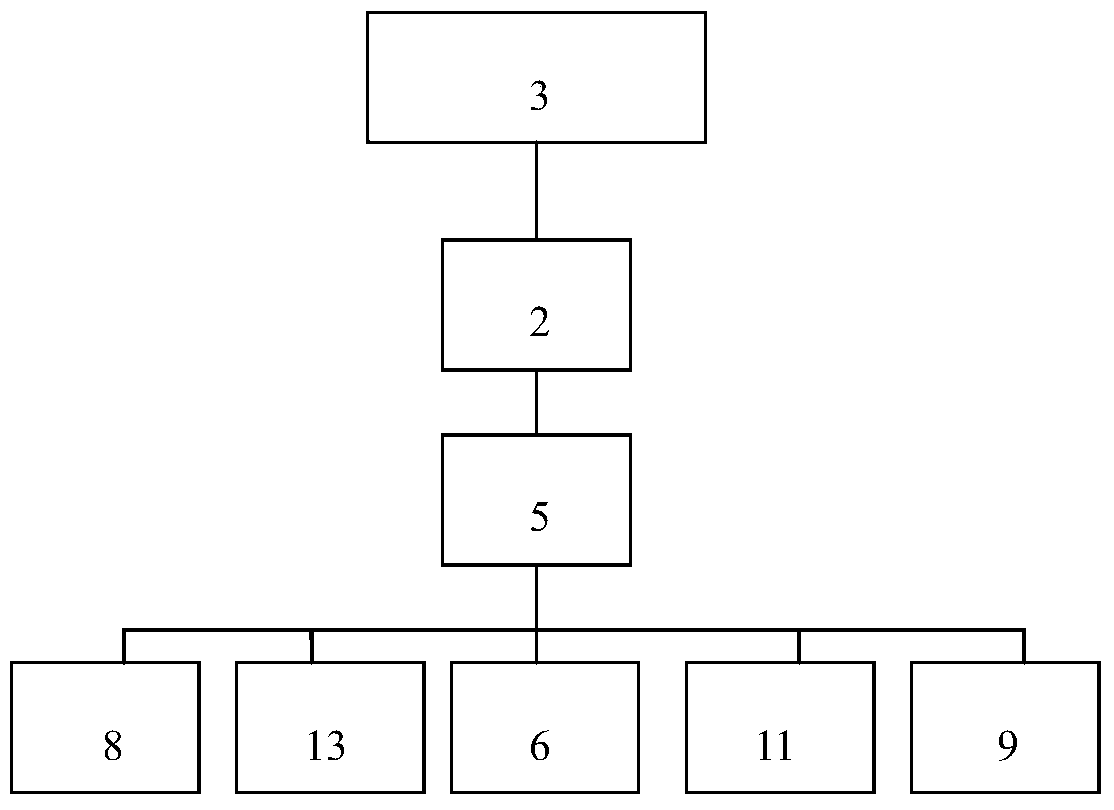

[0038] see figure 1 , according to the input signal type of the digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com