Method for butting flange faces by using butting device

A docking device and docking flange technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of difficult equipment alignment, low installation efficiency, component collision damage, etc., to achieve accurate relative positions and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

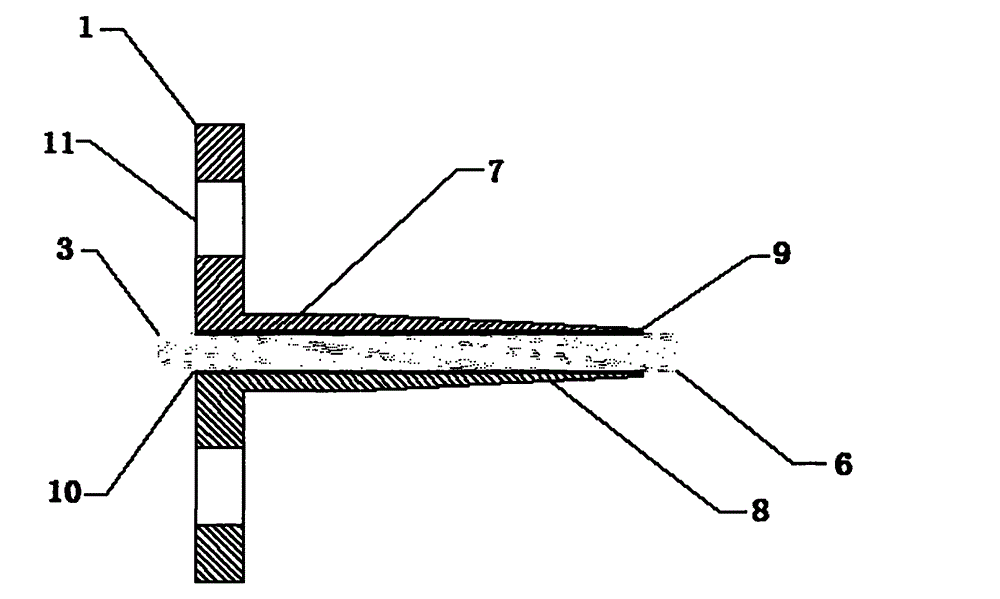

[0018] This embodiment cites an example of applying the method of the present invention to the butt joint of the flange surface of the separate installation of the offshore wind turbine. At this time, the butt joint between the nacelle and the straight flange surface of the hub is completed at high altitude. In this embodiment, the straight flange surface of the hub is called the first flange surface. The flange surface is called the second flange surface, and the first flange surface and the second flange surface each have four mounting holes corresponding to each other, forming four sets of mounting holes, and each set of mounting holes is preferably equipped with a The docking device described in the example is used to complete the docking work with high quality.

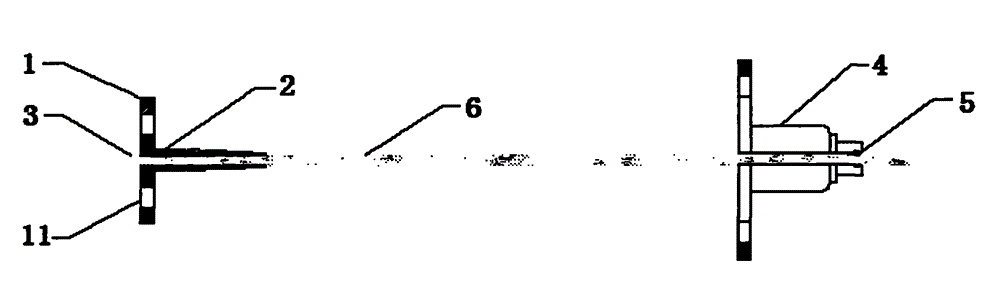

[0019] Each docking device includes a fixed base 1, a docking rope 6, a positioning tube 2, and a braking device that pulls the docking rope 6 in one direction. The positioning pin segment 7 fixedly connected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com