Method and apparatus for aligning screw caps of hollow bodies, especially bottles

A hollow body, air technology, applied in the field of equipment implementing the method, screw closures of bottles, which can solve problems such as dysfunction and slowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

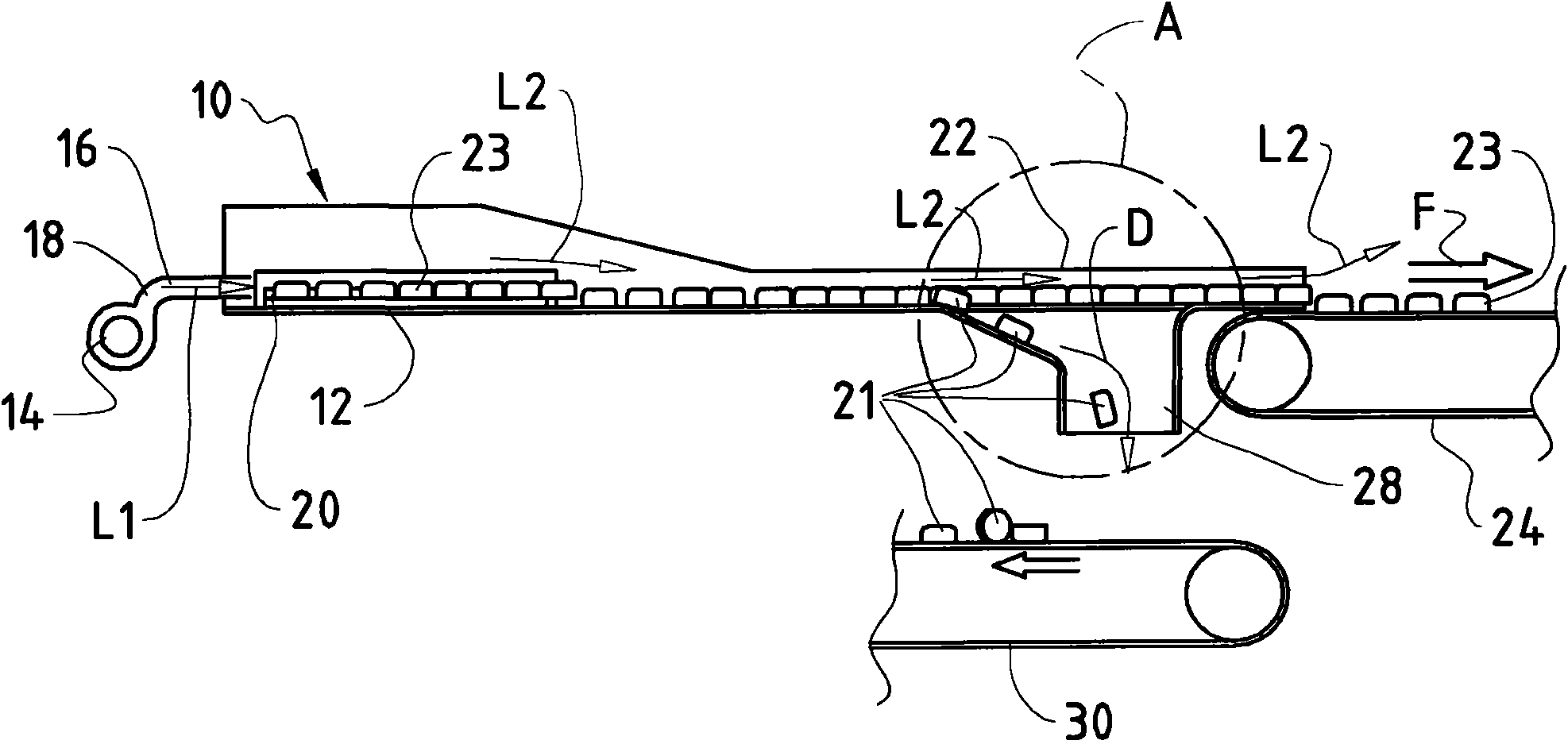

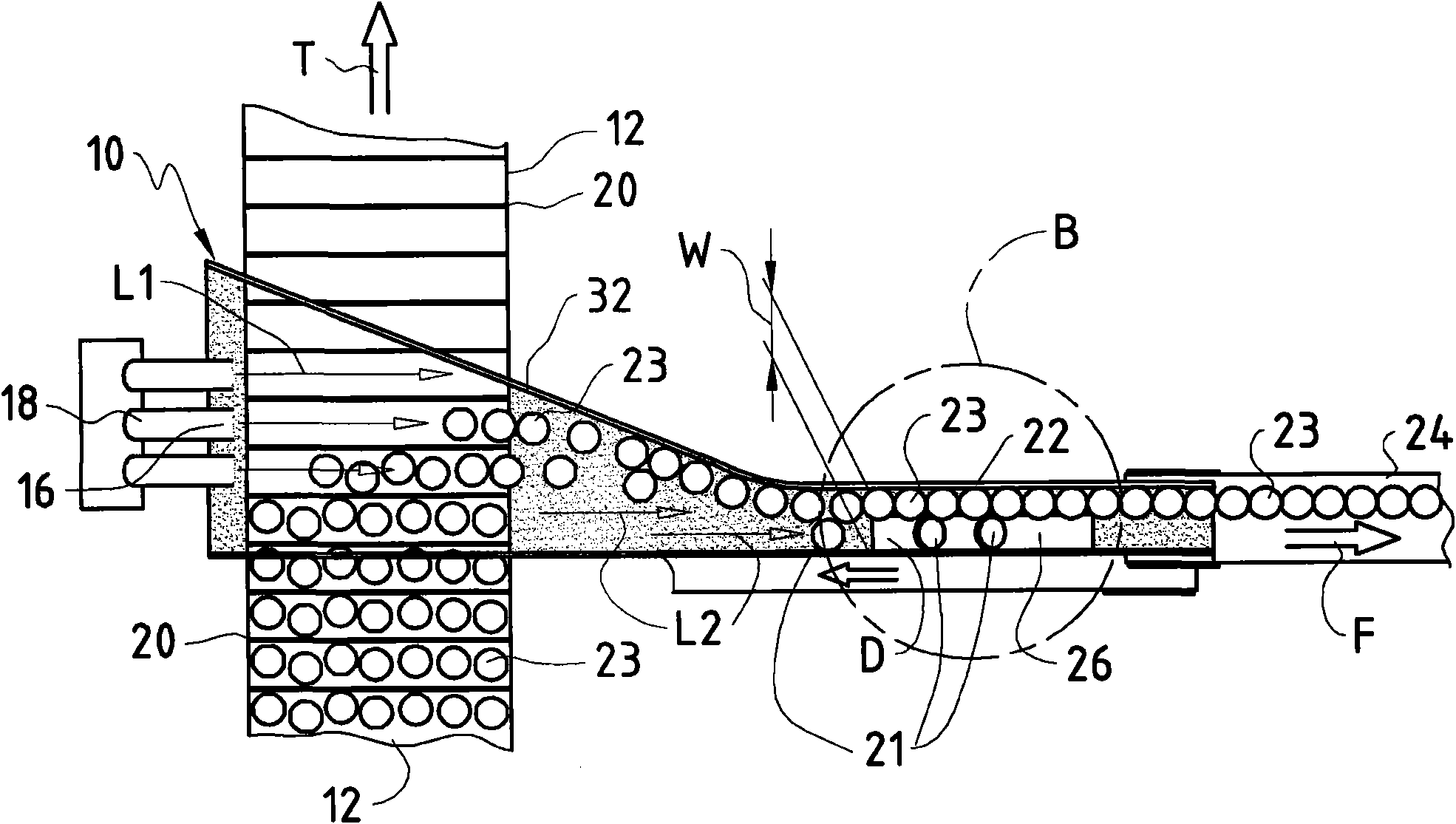

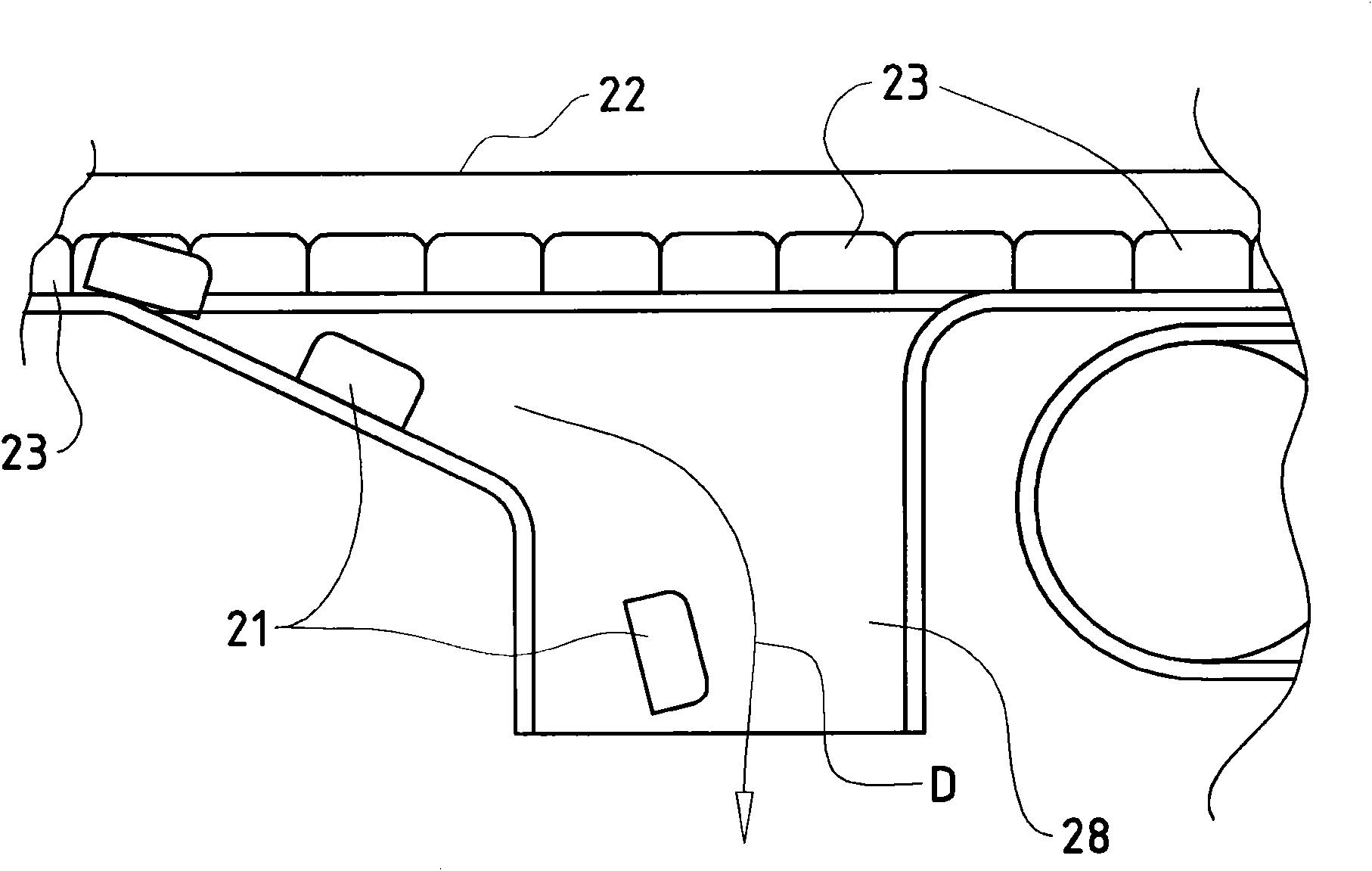

[0033] figure 1 and figure 2 The shown apparatus has a substantially horizontally arranged elongated processing space 10 (hereinafter simply referred to as "chamber"), a conveyor belt 12 passes transversely through the front of the chamber 10 via an air lock (not shown) and along the direction of arrow T direction to move. The conveyor belt 12 is hit from the side or above by the air flow inside the chamber 10 , which is generated by the blower 14 and exits the nozzle box 16 , the output jet opening just adjacent to the conveyor belt 12 . Typically, the direction of action of the air flow on the conveyor belt 12 is skewed from above with respect to the plane of the conveyor belt 12, or with respect to the plane of the processing space 10, so that the hollow bodies to be aligned (lined up) by the air flow are pressed on the one hand. against the bottom surface and on the other hand is pressed laterally.

[0034] If desired, other means (not shown) can also be provided by wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com