Device for heating and/or frothing milk for machines for preparing hot beverages such as a cappuccino

A technology for preparing machines and equipment, applied in beverage preparation devices, applications, household appliances, etc., can solve problems such as the breeding of harmful bacteria groups, and the inability to ensure high and safe sanitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

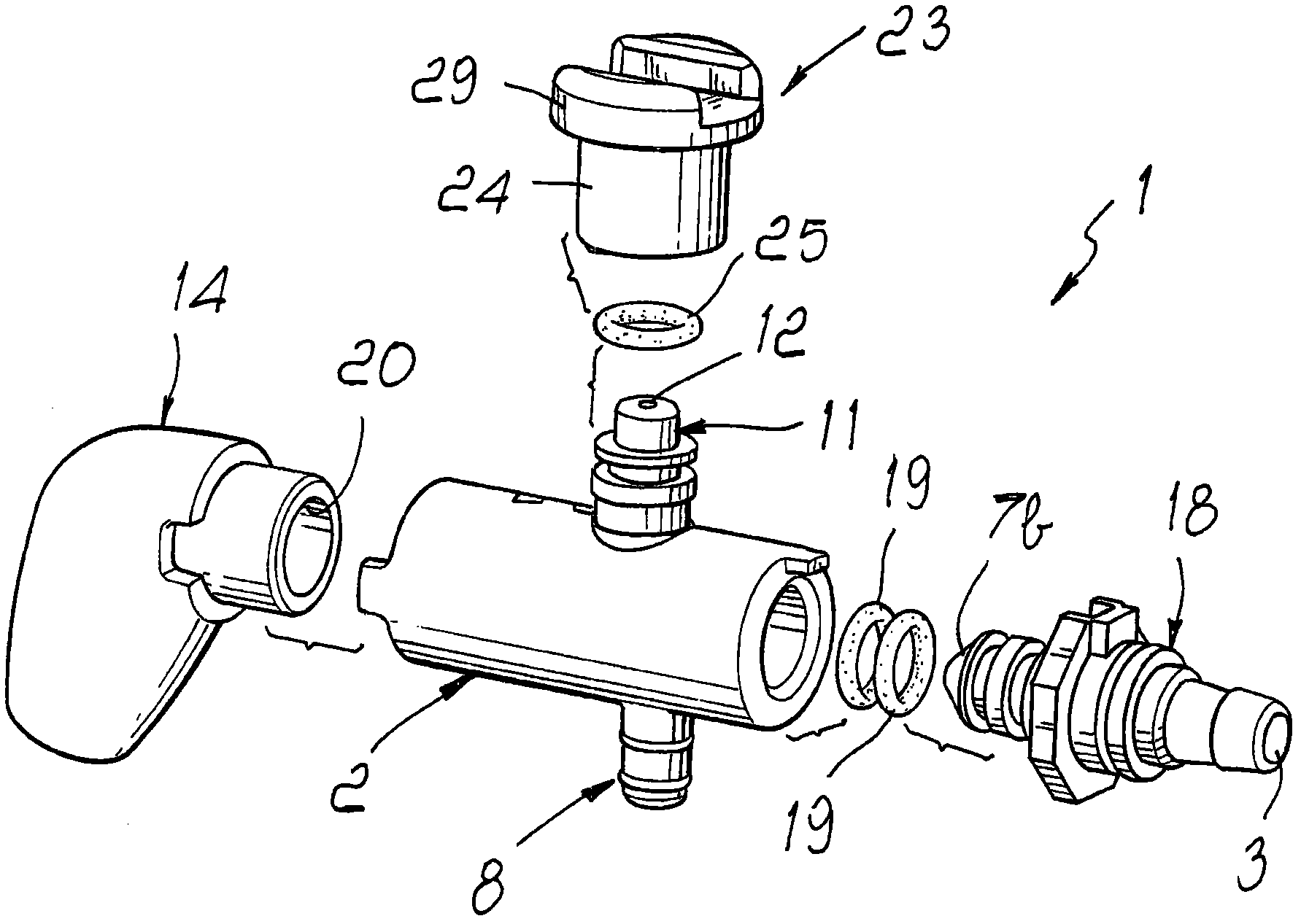

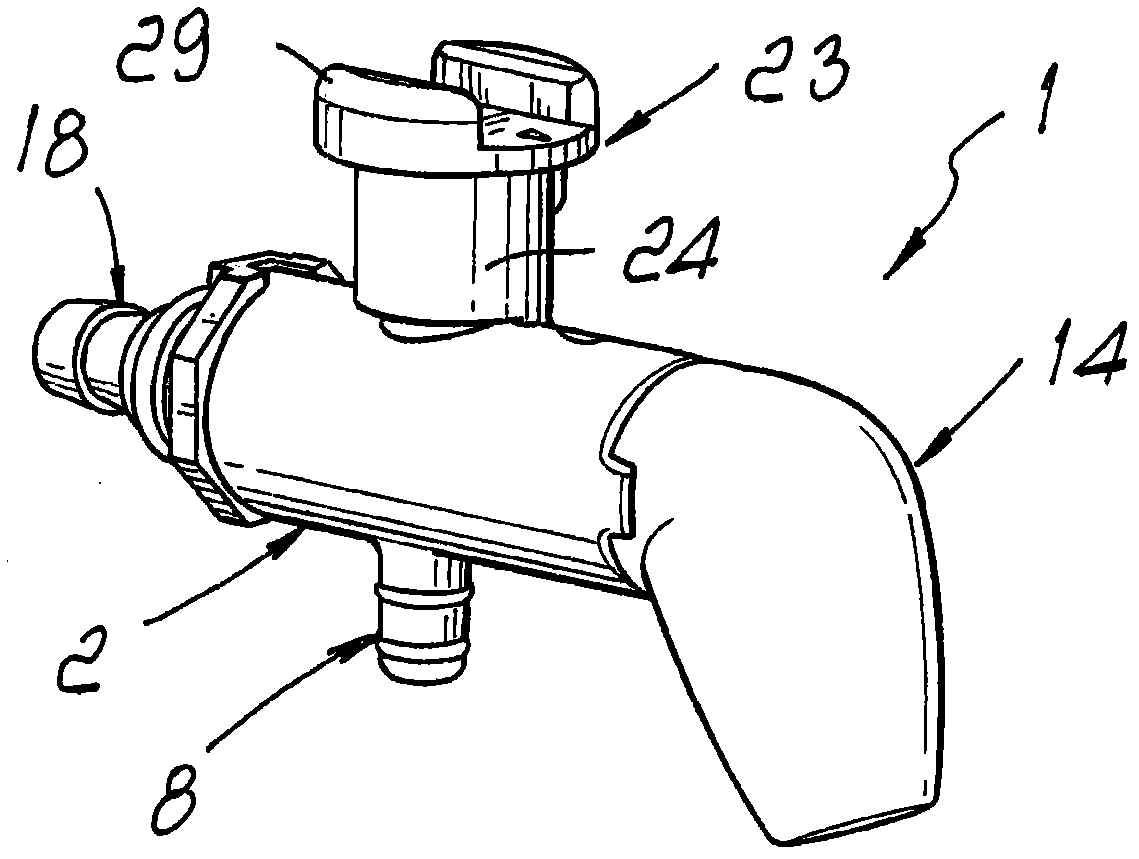

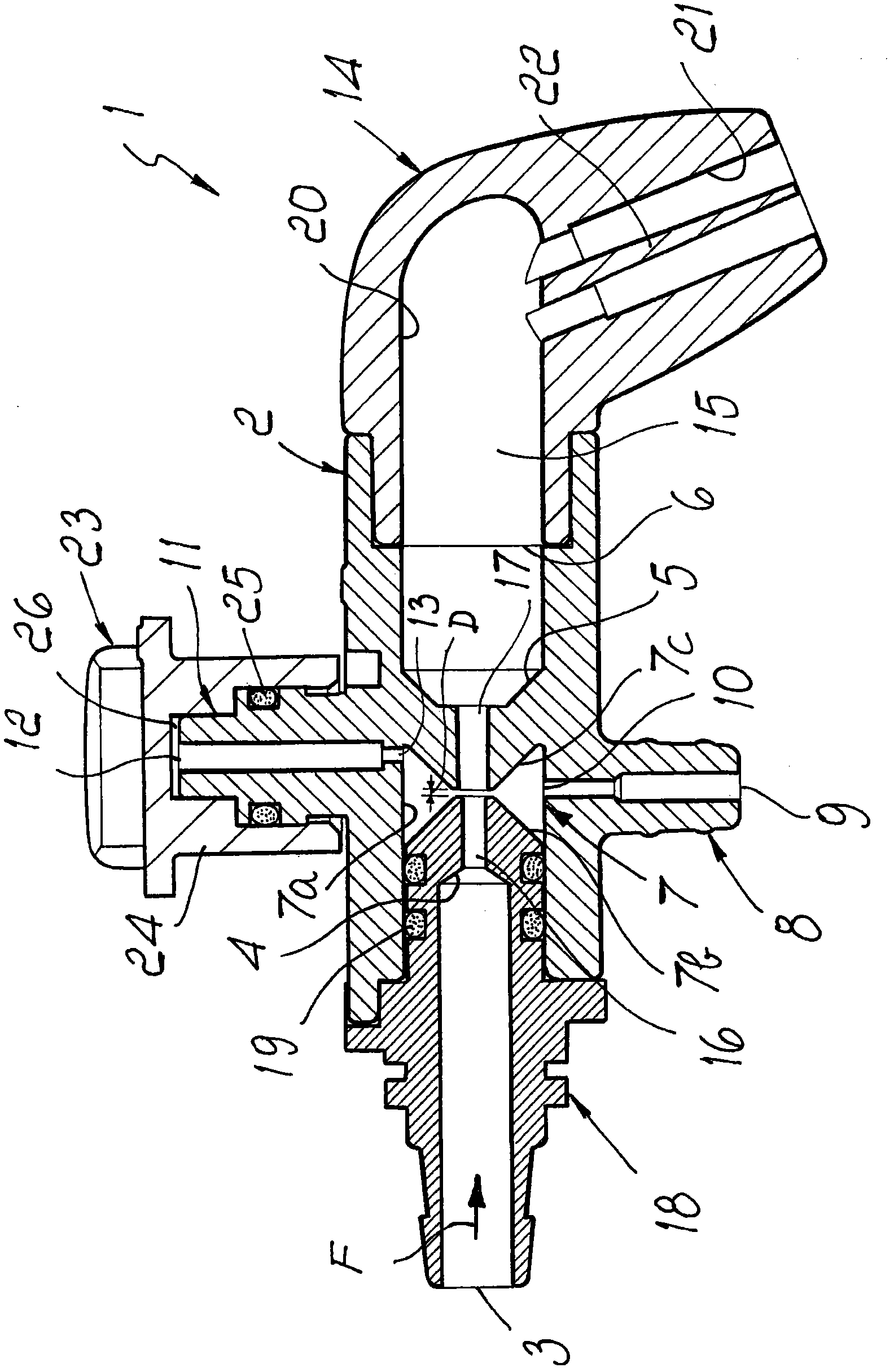

[0026] With reference to the accompanying drawings, reference numeral 1 generally designates a device for heating and / or frothing milk for a machine for preparing hot beverages, such as cappuccino.

[0027] In this specification, the term "substantially" used has the meaning of "corresponding" within the range of tolerance known to those skilled in the art.

[0028] The device 1 comprises a tubular body 2 in which is arranged a venturi comprising a feed end 3 , a converging portion 4 , a diverging portion 5 and a discharge end 6 .

[0029] The feed end 3 can be associated with a steam source such as a boiler, pressurized boiler, transient heat exchanger (thermoblock).

[0030] The steam flow passes through the venturi in the direction indicated by arrow F.

[0031] Between the converging part 4 and the diverging part 5 exists a chamber 7 for mixing the milk with steam and optionally with air from the outside.

[0032] The device 1 also comprises at least one milk supply cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com