Electromechanical liquid intelligent combined belt breakage protective device for belt conveyor

A belt conveyor and protection device technology, which is applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of easy misgiving of capture signals, secondary belt breakage, and high misoperation rate. The effect of reliable capture performance, large capture force and reliable detection signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

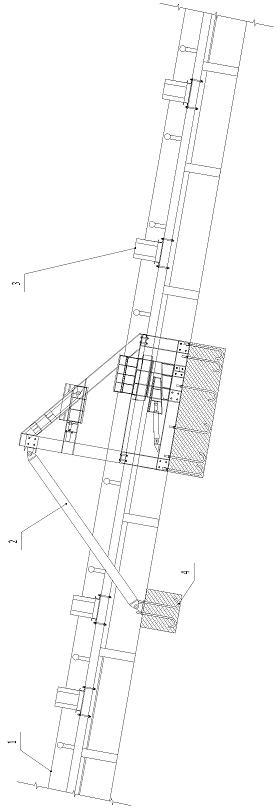

[0026] Such as figure 1 Shown: an electromechanical-hydraulic intelligent combined broken belt protection device for belt conveyor, which is characterized in that the device organically combines two broken belt protection devices: an integral broken belt protection device 2 and a broken belt catcher 3 used, installed on the frame of the belt conveyor; the integral broken belt protection device 2 is located near the head of the belt conveyor, and is fixed on the foundation by anchor bolts 4; the broken belt grab Catcher 3 is a plurality of groups, is distributed in the upstream and downstream of integral broken belt protection device 2, and broken belt catcher 3 is fixed on the frame of belt conveyor by fixing frame bolt group 3-2.

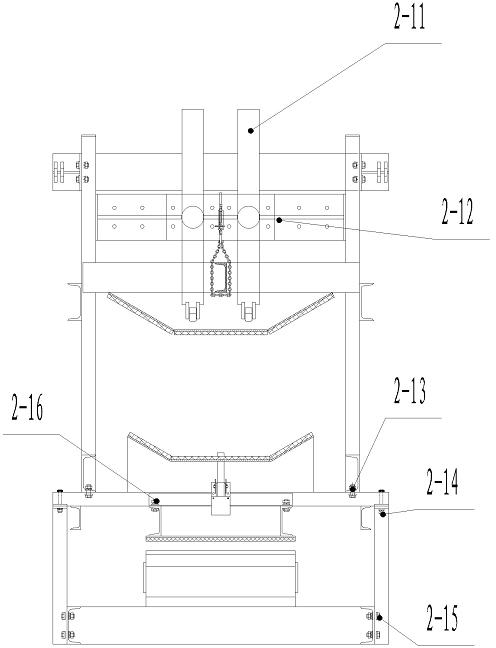

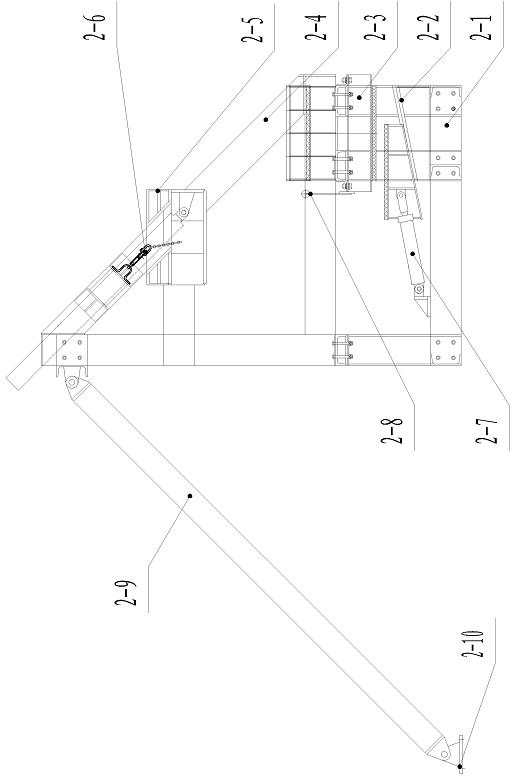

[0027] Such as figure 1 , image 3 As shown: the integral broken belt protection device 2 includes: frame one 2-1, lower belt arresting mechanism 2-2, middle pressing block 2-3, upper belt arresting slide 2-4, upper belt Capture mechanism 2-5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com