Drum type full-section broken belt protection device

A protection device and a full-section technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of secondary damage to the conveyor belt, high price, increased operating costs, etc., to reduce running resistance , no secondary damage, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with all drawings and embodiments.

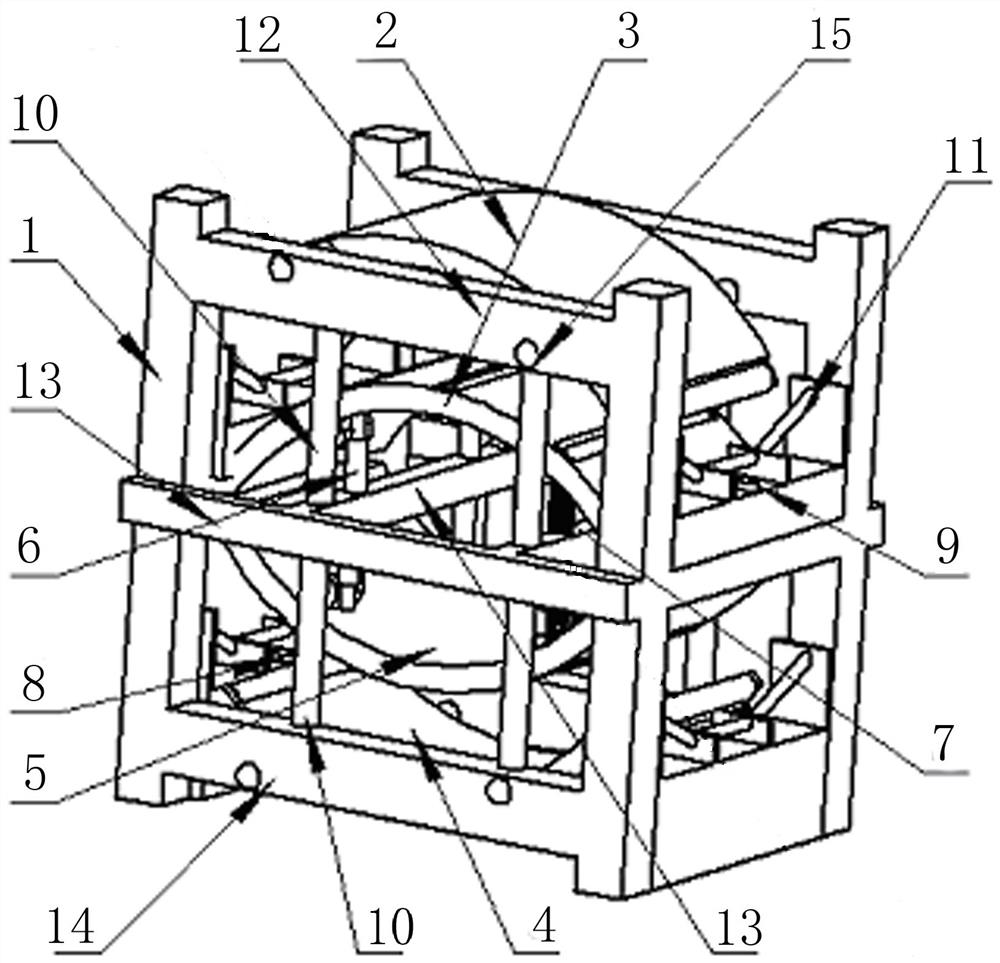

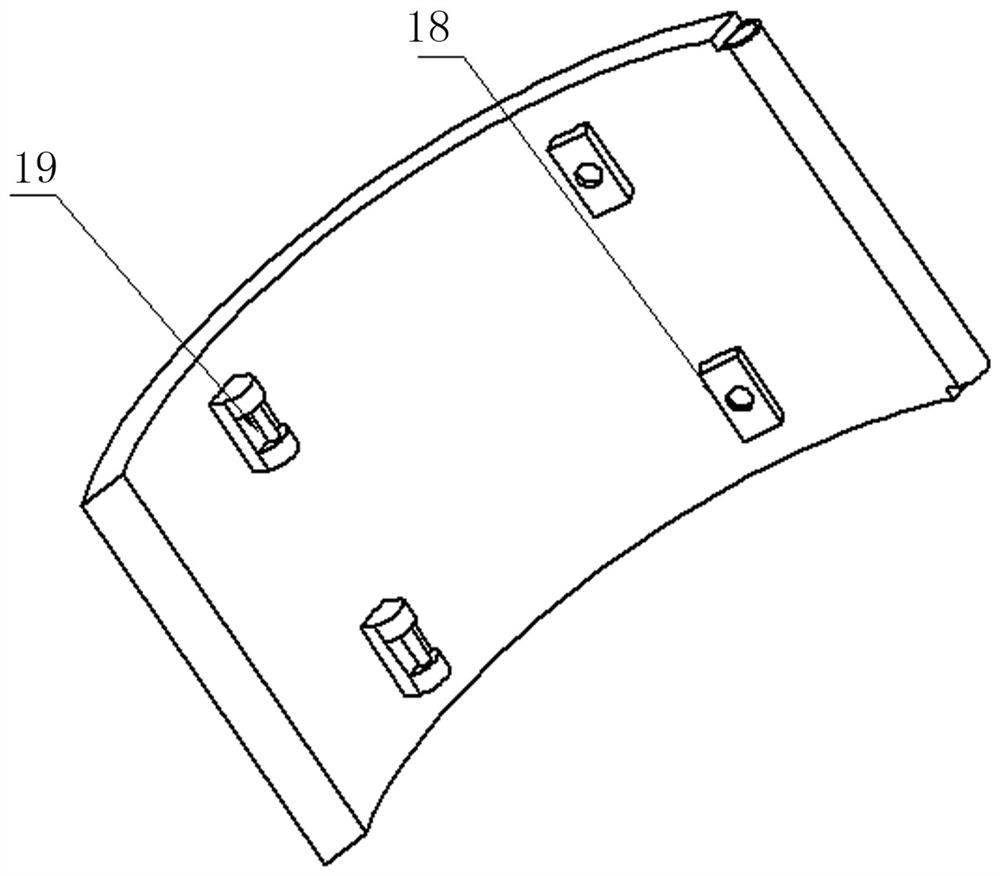

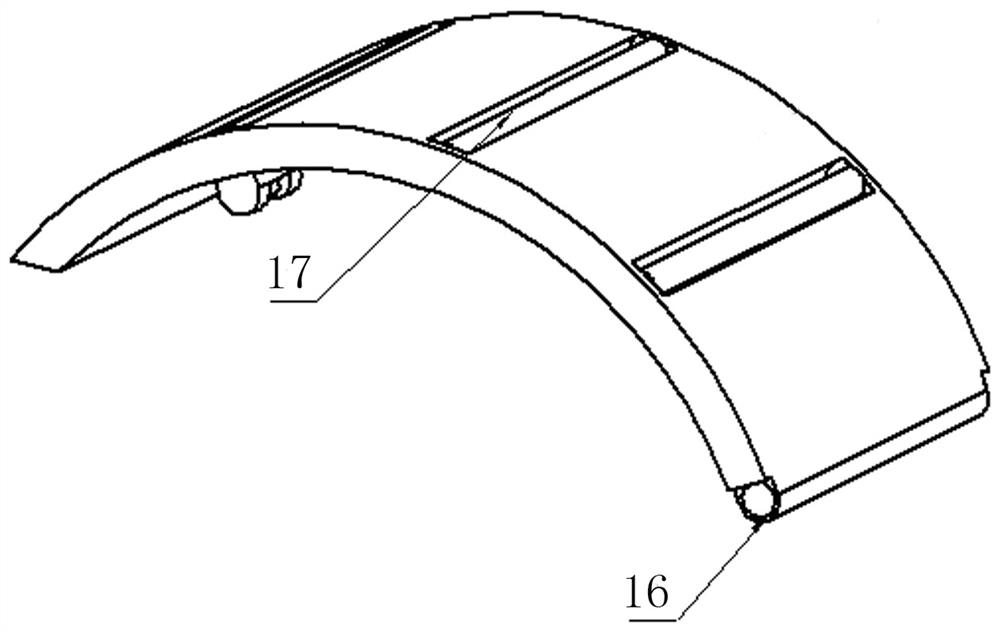

[0024] like figure 1 , 2 The shown drum-type full-section belt-breaking protection device includes a frame 1, an upper fixed friction pair 2, an upper movable friction pair 3, a lower fixed friction pair 4 and a lower movable friction pair 5, a hydraulic cylinder 6, and a circular arc structure. Return spring 7, pressure sensor 8; side rollers 10 are longitudinally arranged on the side of the frame 1, and horizontal belt rollers 11 are arranged in the middle of the frame; the upper fixed friction pair 2 and the upper movable friction pair 3 is installed on the upper part of the frame 1 to form an upper actuator, and the upper movable friction pair 3 can rotate around the rotating shaft to approach the upper fixed friction pair 2; the lower fixed friction pair 4 and the lower movable friction pair 5 are installed on the frame 1. The lower part of the friction pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com