Wedge type full-section belt breakage protection device for upward belt conveyor

A belt conveyor and protection device technology, which is applied to the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of long action stroke, poor operation economy, and increased capture difficulty of the catcher. Achieve the effect of avoiding explosion-proof problems, large grasping force, and eliminating the need for hydraulic power systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

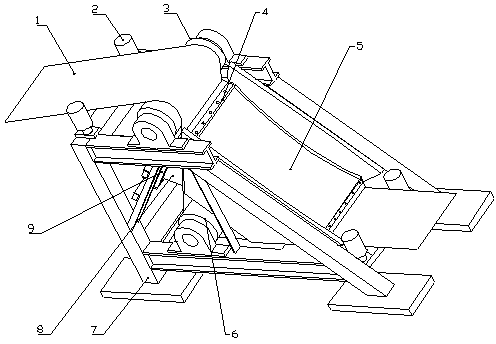

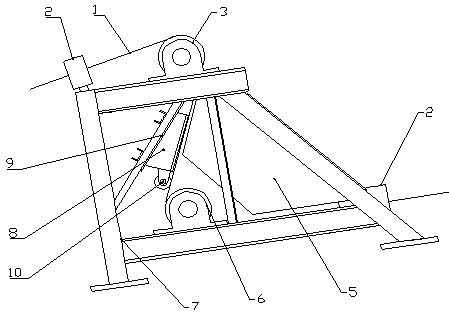

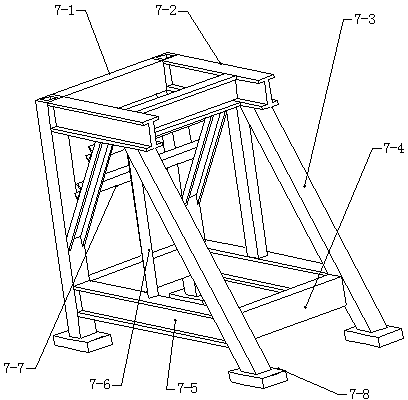

[0013] Such as figure 1 , figure 2 with image 3 As shown, the wedge-type full-section broken belt protection device for an upper belt conveyor of the present invention is mainly composed of a frame 7, a redirection drum 3, a chute 9, a wedge 8, and a material slideway 5. The broken belt The protection device is set along the direction of the belt, and multiple broken belt protection devices can be installed at intervals according to the actual needs of the site. The frame 7 of the broken belt protection device is arranged along the direction of the upward ramp, and is fixed on the foundation through the anchor rod or the anchor bolt through the column foot 7-8. The lower part of the frame 7 is provided with a lower redirecting roller 6, and the belt 1 is wound around the upper and lower redirecting rollers 3 and 6 to form a height difference of 0.5m. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com