Toilet seat device

A technology for toilet seats and toilets, which is applied to water supply devices, seats or covers for toilets, flushing equipment with water tanks, etc., can solve problems such as increased use times, deterioration of relay mechanisms, and influences on the use period and frequency of toilet seat devices. , to achieve the effect of ensuring the exact implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0054] [Basic structure of toilet seat device]

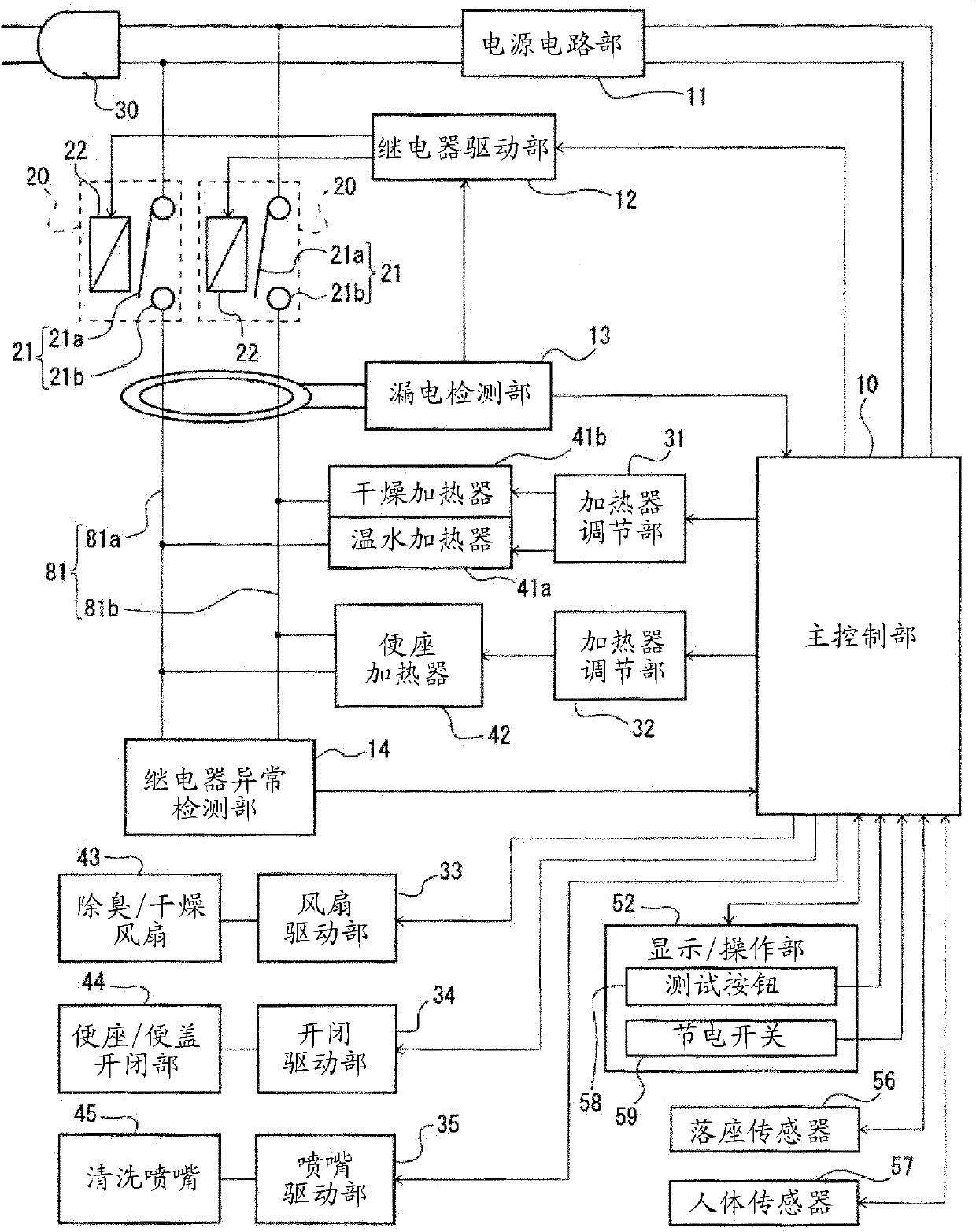

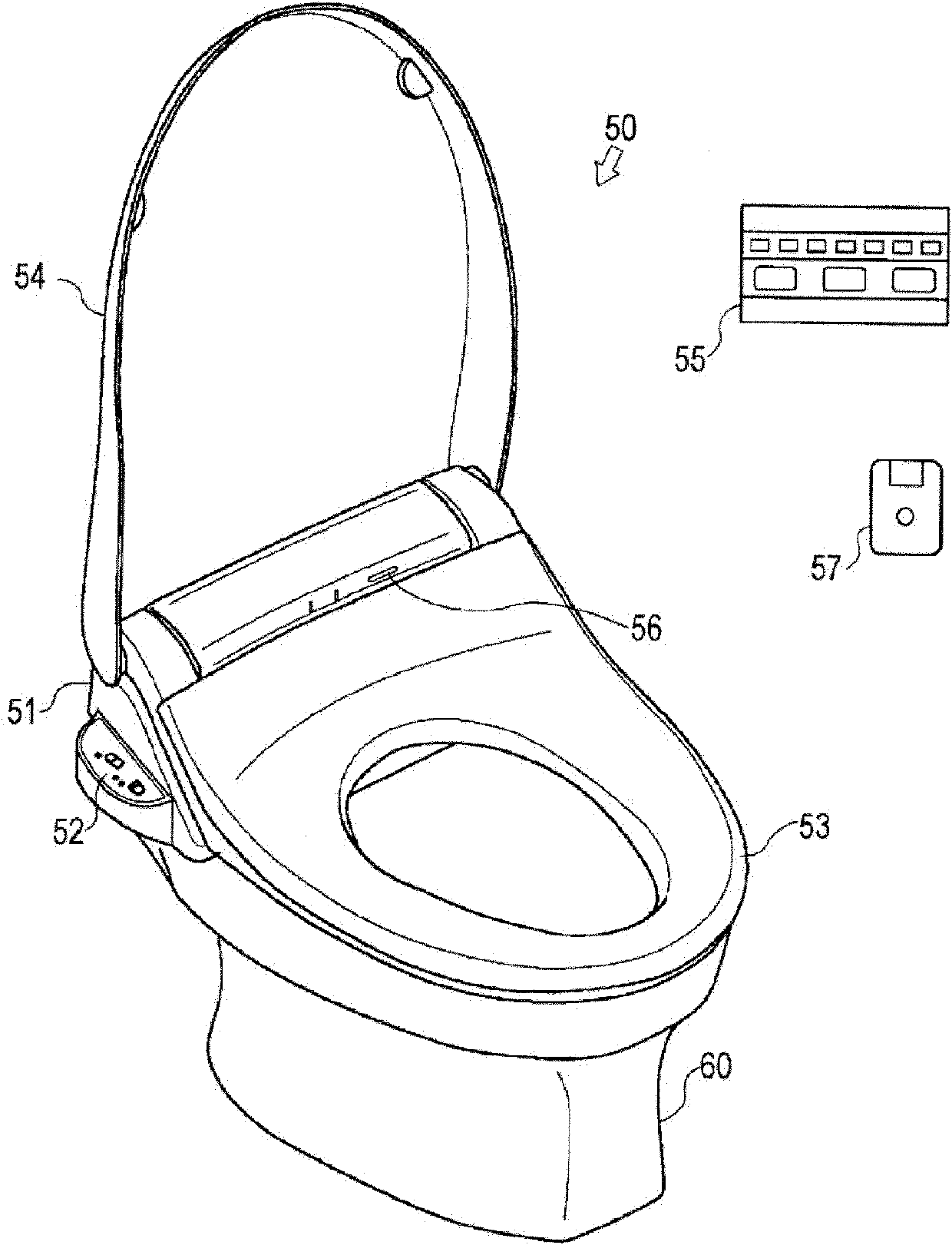

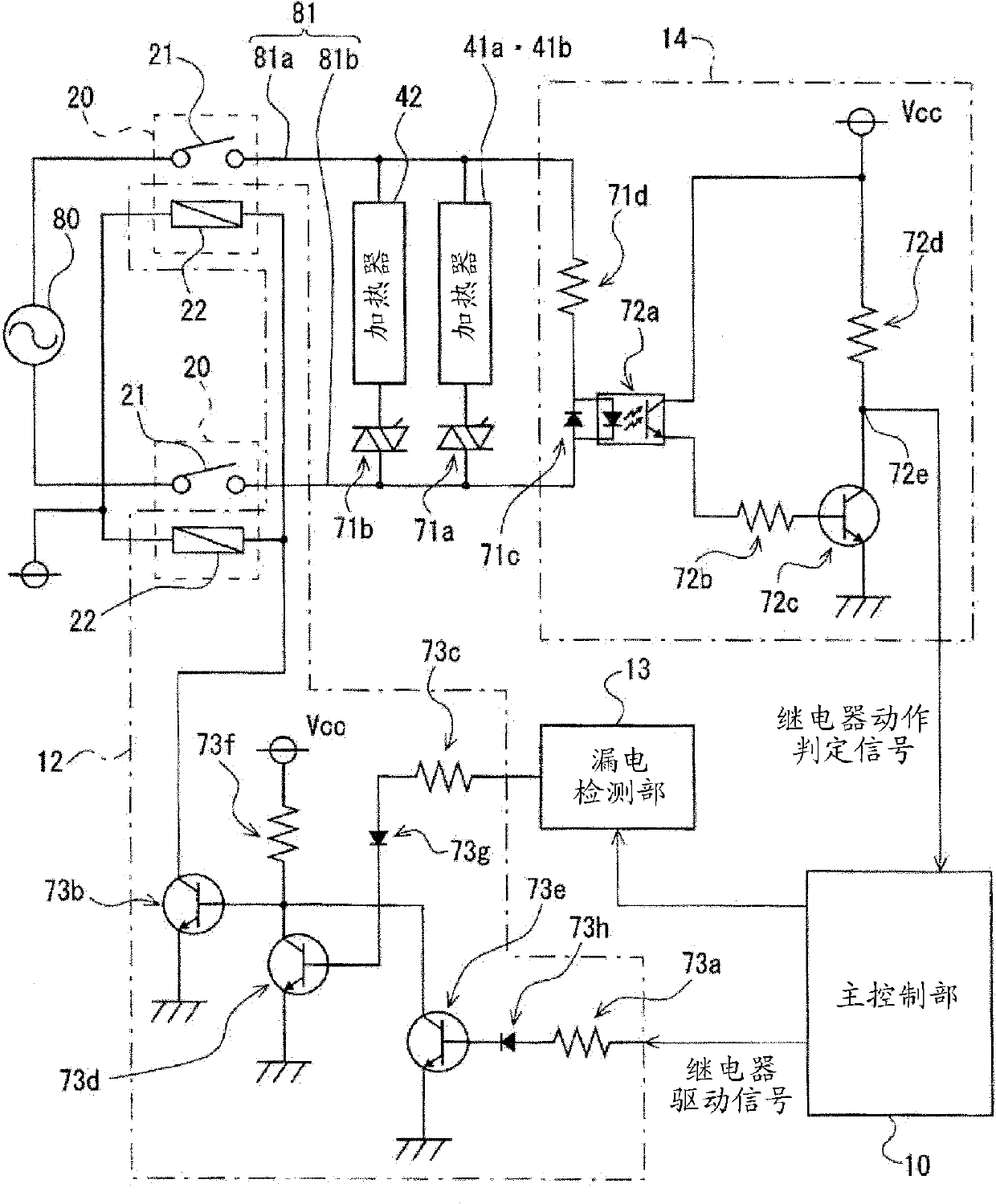

[0055] First, refer to figure 1 and figure 2 The specific structure of the toilet seat device which concerns on this embodiment is demonstrated. figure 1 It is a circuit diagram which shows an example of the electrical structure of the toilet seat apparatus concerning Embodiment 1 of this invention. figure 2 is showing figure 1 It is a schematic perspective view of an example of the external appearance of the toilet seat apparatus shown.

[0056] Such as figure 2 As shown, the toilet seat device 50 of this embodiment has a main body 51 , a display / operation unit 52 , a toilet seat 53 , a toilet cover 54 , a remote controller 55 , a seating sensor 56 , and a human body sensor 57 . The main body part 51, the toilet seat part 53, and the toilet cover part 54 of the toilet seat device 50 are assembled integrally, and are installed in the upper surface of the toilet bowl 60. As shown in FIG. Next, it demonstrates so that the...

Embodiment approach 2

[0115] In Embodiment 1 described above, the main control unit 10 performs the following control: as a confirmation test of the leakage cut-off function, the relay mechanism 20 is tentatively opened and closed, and the presence or absence of an abnormality in the relay is detected by the relay abnormality detection unit 14. In this embodiment, it is also detected whether or not the control of the main control unit 10 itself is properly performed. That is, in the present invention, as described in the first embodiment, it may be configured to detect an abnormality of the relay as an abnormality of the earth leakage cut-off function, but it may also be configured so that the overall control of the toilet seat device 50 by the main control unit 10 (of course When some abnormality occurs in the control including the relay drive unit 12 and the relay mechanism 20, it is detected as an abnormality of the leakage cutoff function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com