Automatic production system for pickled vegetable

An automatic production and vegetable technology, applied in the field of production systems, can solve the problems of human factor pollution, loss of nutrient elements, rupture of vegetable cells, etc., to avoid excessive pressing and ensure the effect of taste.

Inactive Publication Date: 2011-06-15

甘宁

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the production process of vegetable pickled vegetable instant food basically follows the traditional handicraft workshop process, and there are many problems. After many times of water-soluble desalination, the nutritional content of vegetables is seriously lost; and in order to prevent corrosion, the raw vegetables are directly pickled without washing, and the hygienic indicators are extremely poor; second, the pressing and dehydration process is extremely unscientific, often over-pressing, resulting in vegetable cells Rupture, exudation of cell fluid, loss of a large amount of nutrients, the texture of the product is soft and not brittle, and the taste is poor

The third is full manual operation, the production efficiency is extremely low, the cost is high, and the pollution caused by human factors is inevitable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

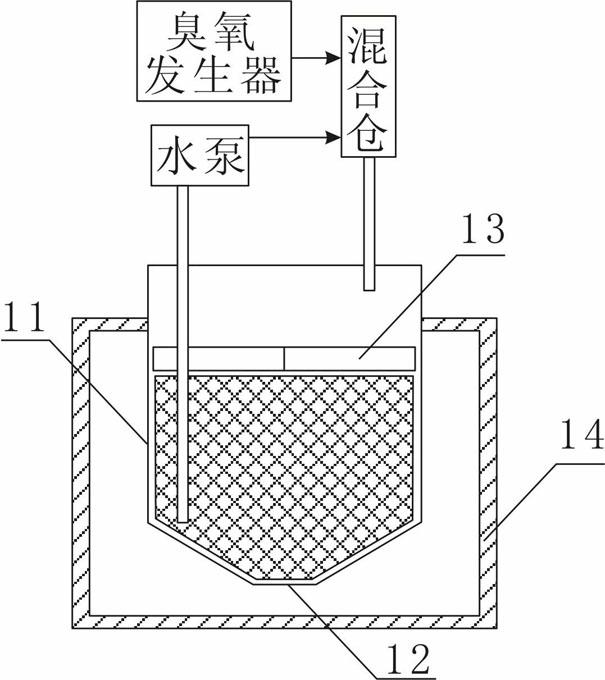

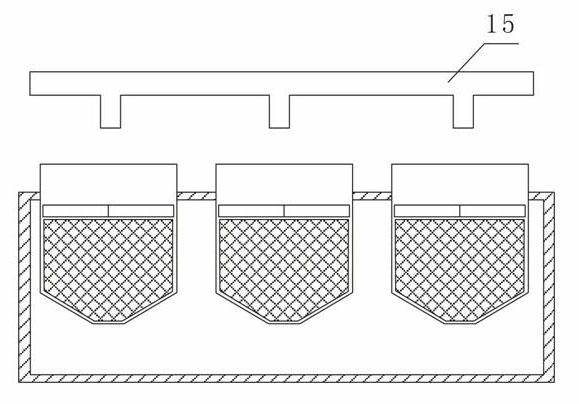

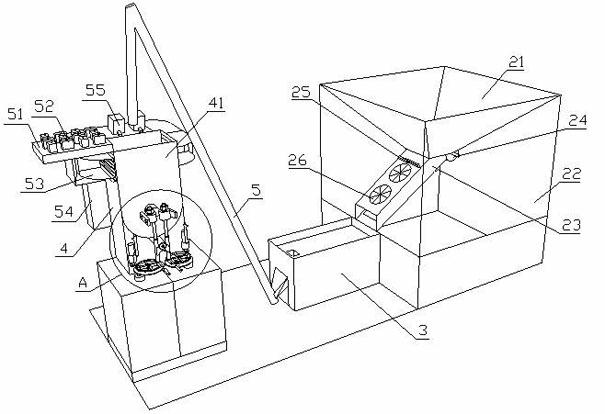

The invention discloses an automatic production system for pickled vegetable. The automatic production system comprises a fermenting device, a cutting device, a packing device and an automatic control device, wherein the devices are all arranged in a sterile bin; the fermenting device comprises multiple fermenting pools; a water outlet is arranged at the bottom of each fermenting pool; a weight squeezing the vegetable is arranged in the fermenting pool; the average density of the weight is equal to or slightly greater than the density of free water squeezed from the pickled vegetable; one side of the fermenting pool is provided with a circular sterilizing device; a transmission belt for delivering vegetable into the fermenting pool is arranged above the fermenting pool; the outer wall of the fermenting pool is provided with a temperature control device; a manipulator for moving the weight and the vegetable is also arranged in the sterile bin; and the automatic control device is electrically connected with the devices, the transmission belt and the manipulator and controls the devices, the transmission belt and the manipulator to work coordinately. In combination with a low-salt pickling process, the automatic production system disclosed by the invention is suitable for low-salt pickling, and can avoid excessive squeezing of the vegetable and effectively ensure the mouthfeel ofthe finished product in the squeezing process; and moreover, the entire production process does not involve manual operation, thus manmade pollution is avoided.

Description

Automatic Production System for Pickled Vegetables technical field The invention relates to a production system, in particular to an automatic production system for pickled vegetables. Background technique Pickled vegetable instant food such as pickled mustard, dried radish, pickled green pepper, pickled cucumber, pickled kohlrabi, etc. are people's favorite food for meals, especially for travel meals, and the market demand is very large. At present, the production process of vegetable pickled vegetable instant food basically follows the traditional handicraft workshop process, and there are many problems. After many times of water-soluble desalination, the nutritional content of vegetables is seriously lost; and in order to prevent corrosion, the raw vegetables are directly pickled without washing, and the hygienic indicators are extremely poor; second, the pressing and dehydration process is extremely unscientific, often over-pressing, resulting in vegetable cells Rupt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L1/218A23L19/20

Inventor 甘宁

Owner 甘宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com