Multi-stage humidification powder dedusting method and device for cyclic dedusting

A technology of dust removal device and humidification device, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of easy adhesion of gas ash, affecting the surrounding environment, difficult unloading and loading conditions, etc. Difficulty in adjusting water volume and reducing the effect of difficulty in operation and maintenance

Active Publication Date: 2011-06-15

欧阳汉平

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Blast furnace gravity dust collector background technology: At present, the domestic blast furnace gravity dust collector ash unloading and loading equipment is mainly a double-shaft stirring humidifier, and there are several problems: the humidification water volume is not easy to adjust during the blast furnace gravity dust collector unloading and loading operation, If the amount of water is too large, it will be muddy; if the amount of water is small, a large amount of dry ash that has not been humidified will cause serious dust; due to the high pressure of the blast furnace dust collector, the discharged gas ash entrains gas, and the high temperature of the gas ash in the blast furnace gravity dust collector is as high as 150 ° C. Humidification with water produces a large amount of water vapor, and part of the gas ash that has not been stirred and humidified is spewed out by water vapor and gas, resulting in a large amount of dust in the ash transportation area, and poisonous and harmful mixed gases such as gas, dust, and water vapor are everywhere. Diffuse seriously pollutes the on-site environment; gas, dust, water vapor and other toxic and harmful mixed gases diffuse everywhere, affecting the safety and health of on-site ash unloading workers; gas, dust, water vapor and other toxic and harmful mixed gases diffuse everywhere, and observe the ash discharge on site The loading situation is relatively difficult, which often causes the loading dust to spill out of the compartment, causing pollution on the working ground, etc., and then affecting the surrounding environment; equipment is easy to be blocked, and gas ash is easy to adhere to the blades of the dual-axis agitating humidifier, causing equipment jams Blockage, poor material conveying, large amount of operation and maintenance

However, the application of the above-mentioned technology has not completely solved the above-mentioned problems. The reason is that the high-temperature dust at 150°C will generate a large amount of water vapor during the humidification process. The water vapor will cause the gas ash and gas to spew out, and the water vapor still contains The diffusion of dust and dusty gas will still cause the above problems

However, there is no relevant literature on how to solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

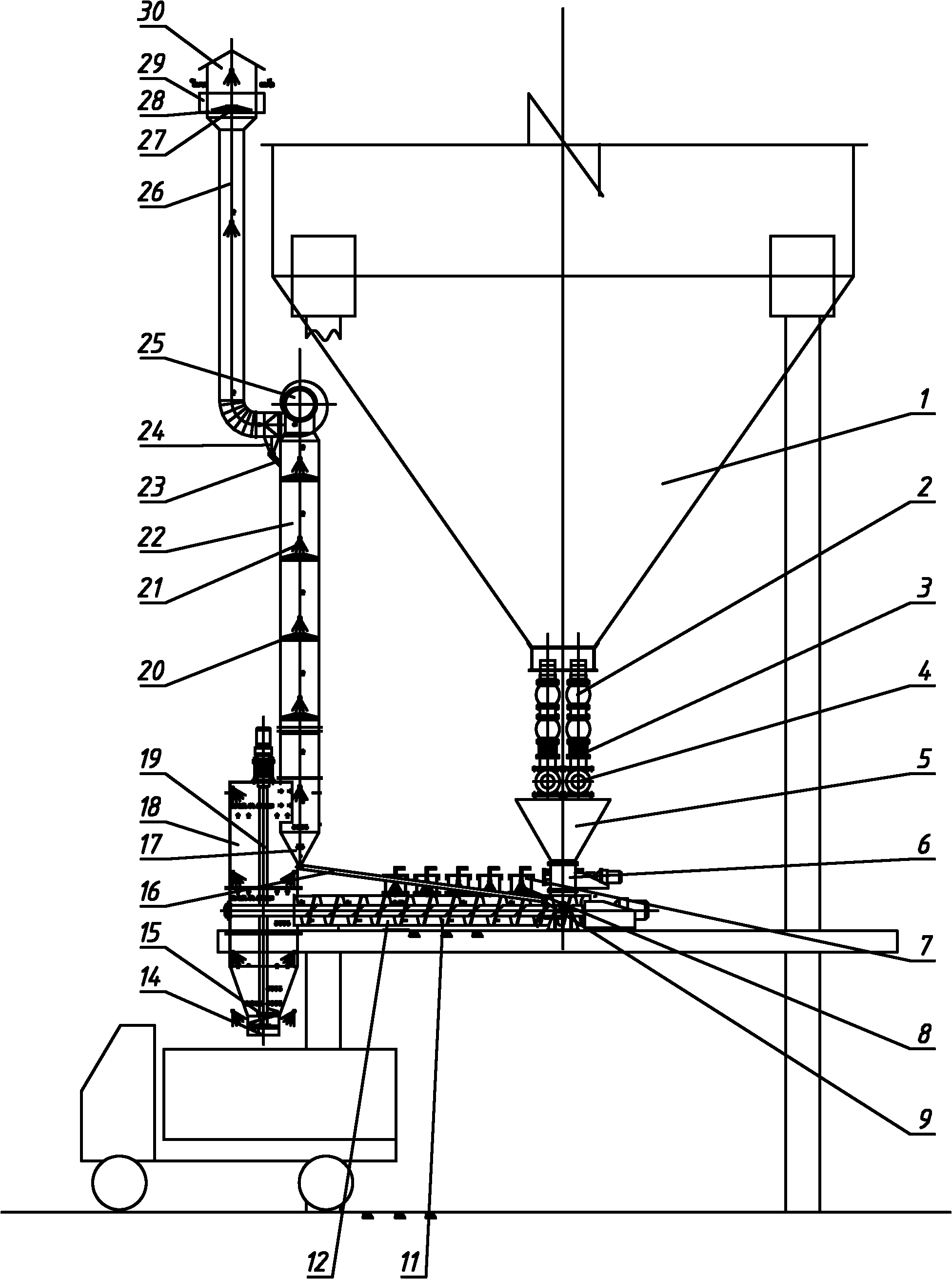

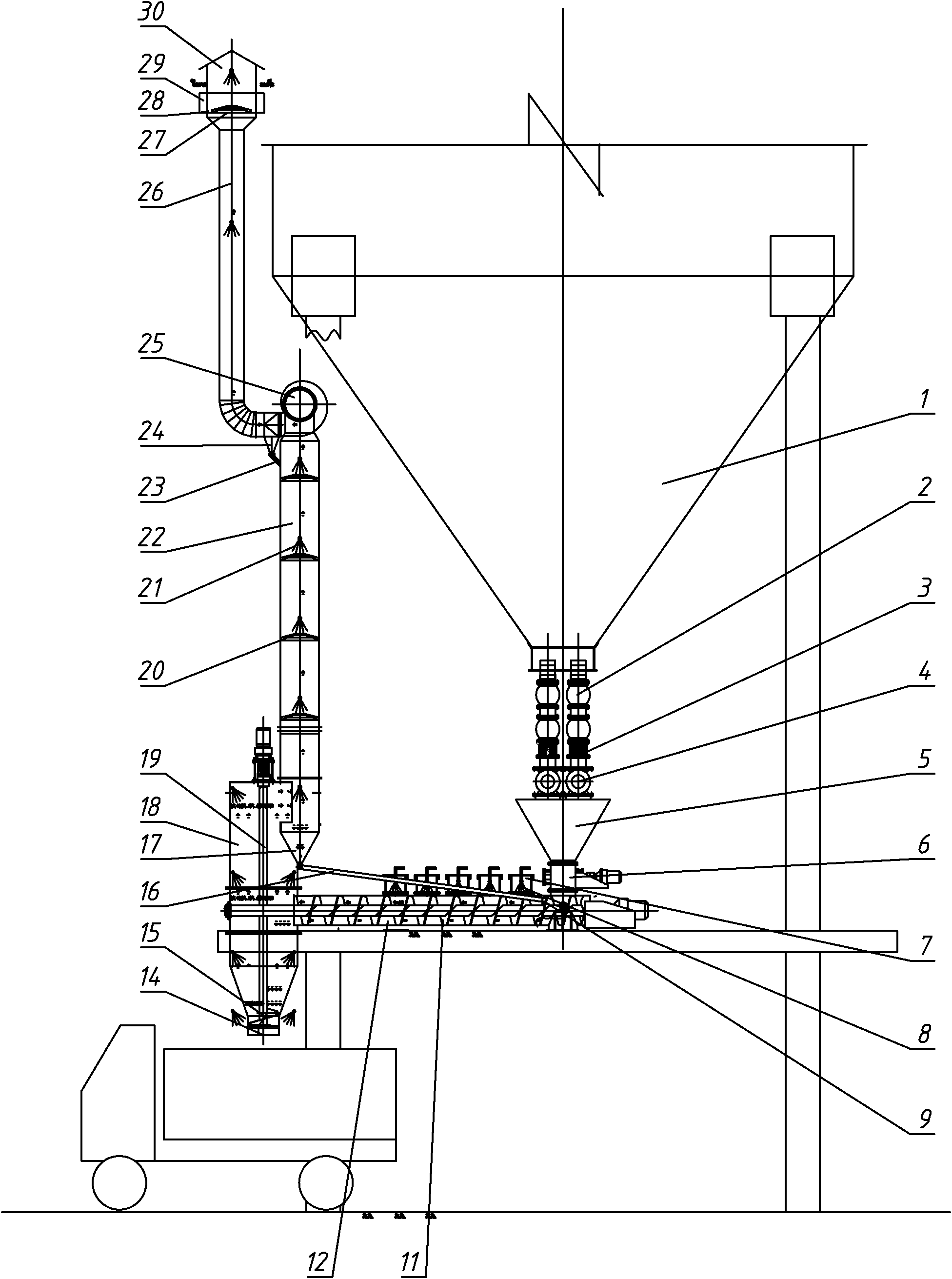

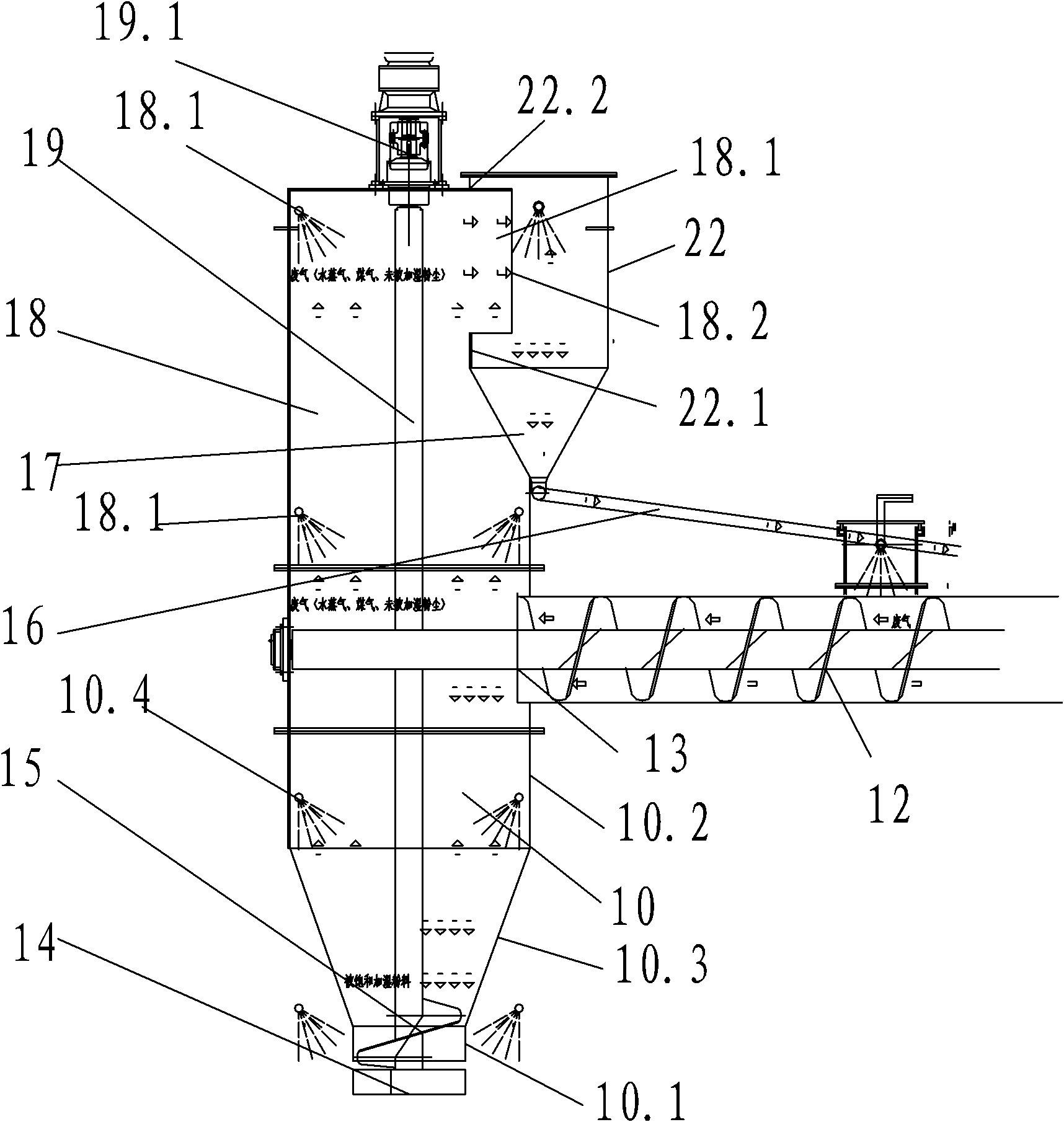

The invention discloses a multi-stage humidification powder dedusting method and a multi-stage humidification powder dedusting device for cyclic dedusting. The method comprises the following steps of: conveying output powder by using a conveyor device, performing first-stage humidification on the powder in the conveyor device, at least performing second-stage humidification on the powder which is not fully humidified and discharging the powder; and simultaneously performing suction separation on dust-containing gases produced by the humidification and treating the gases by utilizing a wet dedusting method. In the method and the device, the dust-containing gases are treated by adopting the wet dedusting method, dedusting wastewater is used for cyclically humidifying the powder, a water volume is extremely easy to regulate and control, the humidified powder stably keeps a critical saturation state and the problems of difficulties of conventional equipment in water volume adjustment are solved.

Description

Circular re-dedusting multi-stage humidification powder dedusting method and device technical field The invention belongs to the gravity dedusting technology, in particular to a multi-stage humidifying powder dedusting technology for unloading ash from a blast furnace gravity deduster. Background technique Blast furnace gravity dust collector background technology: At present, the domestic blast furnace gravity dust collector ash unloading and loading equipment is mainly a double-shaft stirring humidifier, and there are several problems: the humidification water volume is not easy to adjust during the blast furnace gravity dust collector unloading and loading operation, If the amount of water is too large, it will be muddy; if the amount of water is small, a large amount of dry ash that has not been humidified will cause serious dust; due to the high pressure of the blast furnace dust collector, the discharged gas ash entrains gas, and the high temperature of the gas ash in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G69/20B65G69/18

Inventor 欧阳汉平

Owner 欧阳汉平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com