Method for determining blending proportion of expanded cut stem in cut tobacco

A technology of proportion and stem, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult separation, low efficiency, complicated process, etc.

Inactive Publication Date: 2011-06-15

CHINA TOBACCO ZHEJIANG IND

View PDF4 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Chinese patent applications 200610018051.2, 200610018050.8, and 200910065223.5 all use the difference in apparent density of tobacco materials with different blending components in the shredded tobacco, and use the method of configuring organic solvents with different densities to separate the different blending components in the shredded tobacco, and then obtain the blended tobacco. The blending ratio of compound in shredded tobacco, because the density of expanded shredded tobacco is quite different from other blended substances in shredded blended tobacco, the method of the above patent can effectively separate the shredded shredded expanded leaf, but in the actual process, the expanded shredded stem The density difference between silk, leaf silk and flake silk is very small, it is not easy to select an organic solvent with a suitable density to separate it

However, the method involved in Chinese patent application 200610018085.8 is to manually select under a magnifying glass according to the different appearance characteristics of each blending component in the shredded tobacco. Determination of silk blending ratio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Login to View More

Abstract

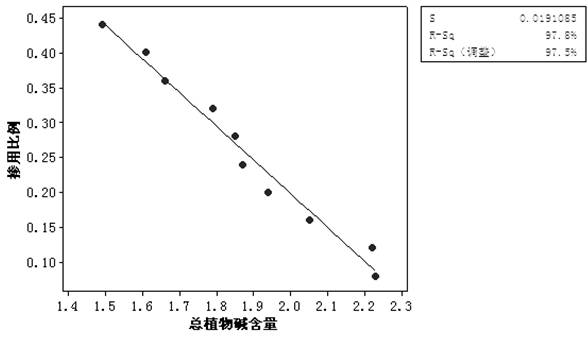

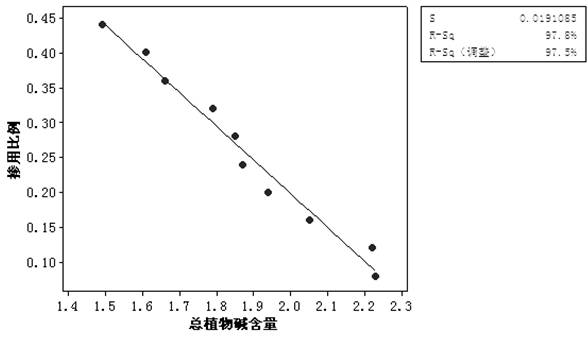

The invention relates to a method for determining the blending proportion of expanded cut stem in cut tobacco. The method comprises the following steps of: a, manually blending the expanded cut stem with other components of the cut tobacco according to a preset blending proportion and recording the proportional value; b, balancing the blended cut tobacco; c, determining the total plant alkaloid content of the balanced cut tobacco by utilizing a flow analyser; d, fitting according to the value of the total plant alkaloid content and the recorded blending proportional ratio value to obtain an expanded cut stem blending proportion predicting model; e, balancing the cut tobacco in formula content the expanded cut stem blending proportion of which is required to be determined in the actual process; f, determining the total plant alkaloid content of the balanced cut tobacco by utilizing the flow analyser; and g, calculating the expanded cut stem blending proportion of the cut tobacco in formula content in the actual process. By applying the invention, technical parameters can be provided for correctly controlling the blending proportion of the cut stem in the cut tobacco in formula content, and support can be provided for stabilizing the physical quality and sensory quality of cigarette products.

Description

A method for measuring the blending ratio of expanded cut stems in shredded tobacco technical field The invention relates to a method for measuring the mixing ratio of expanded cut stems in shredded tobacco. Background technique Tobacco stems account for about 30% of the total tobacco leaves and are the main by-products of the tobacco industry. Due to their high cellulose content and low sugar and alkali components, tobacco stems are usually used as shredded stems or made into thin sheets to increase the filling value of cigarettes. It is beneficial to reduce coke, which is also one of the main ways to utilize tobacco stems. The various blends in the formula shredded tobacco mainly include: shredded leaves, shredded expanded leaves, shredded expanded stems, paper-making flakes, rolling flakes, shredded flakes, and the like. At present, domestic tobacco companies usually use part of the expanded shredded stem as the ingredient tobacco and roll it into finished cigarettes....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N30/00

Inventor 周小忠丁伟孙哲建胡雅军邵长岭闫洪喜刘建华

Owner CHINA TOBACCO ZHEJIANG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com