Rotary connecting device

A technology of rotating connection and rotating part, applied in the direction of flexible/rotatable wire connector, connection, three-pole connection, etc., can solve the problems of affecting signal transmission and easily damaged wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

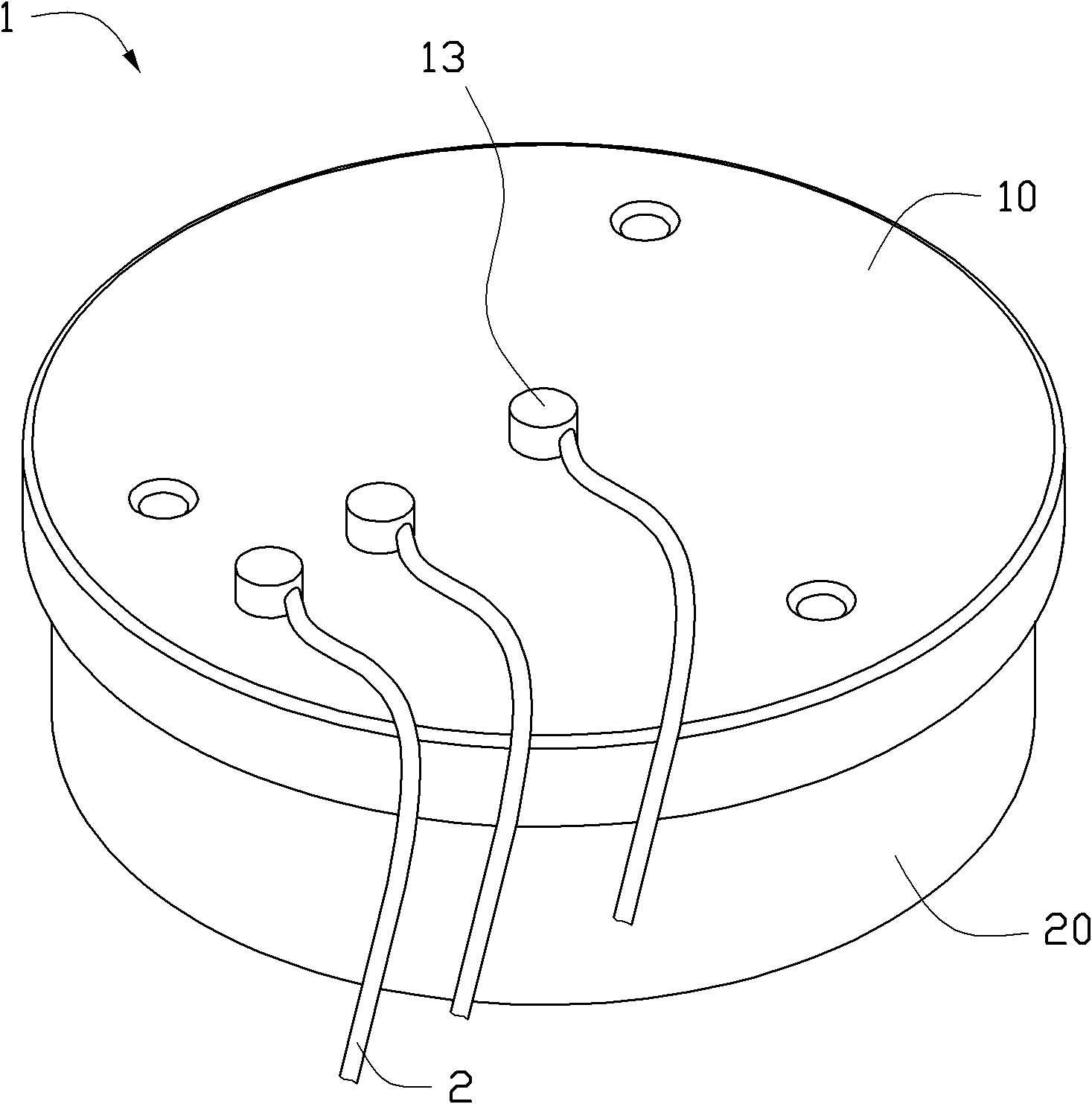

[0012] see figure 1 , the rotating connection device 1 includes a first rotating part 10 and a second rotating part 20 respectively connected with wires 2 , wherein the second rotating part 20 can rotate around the first rotating part 10 .

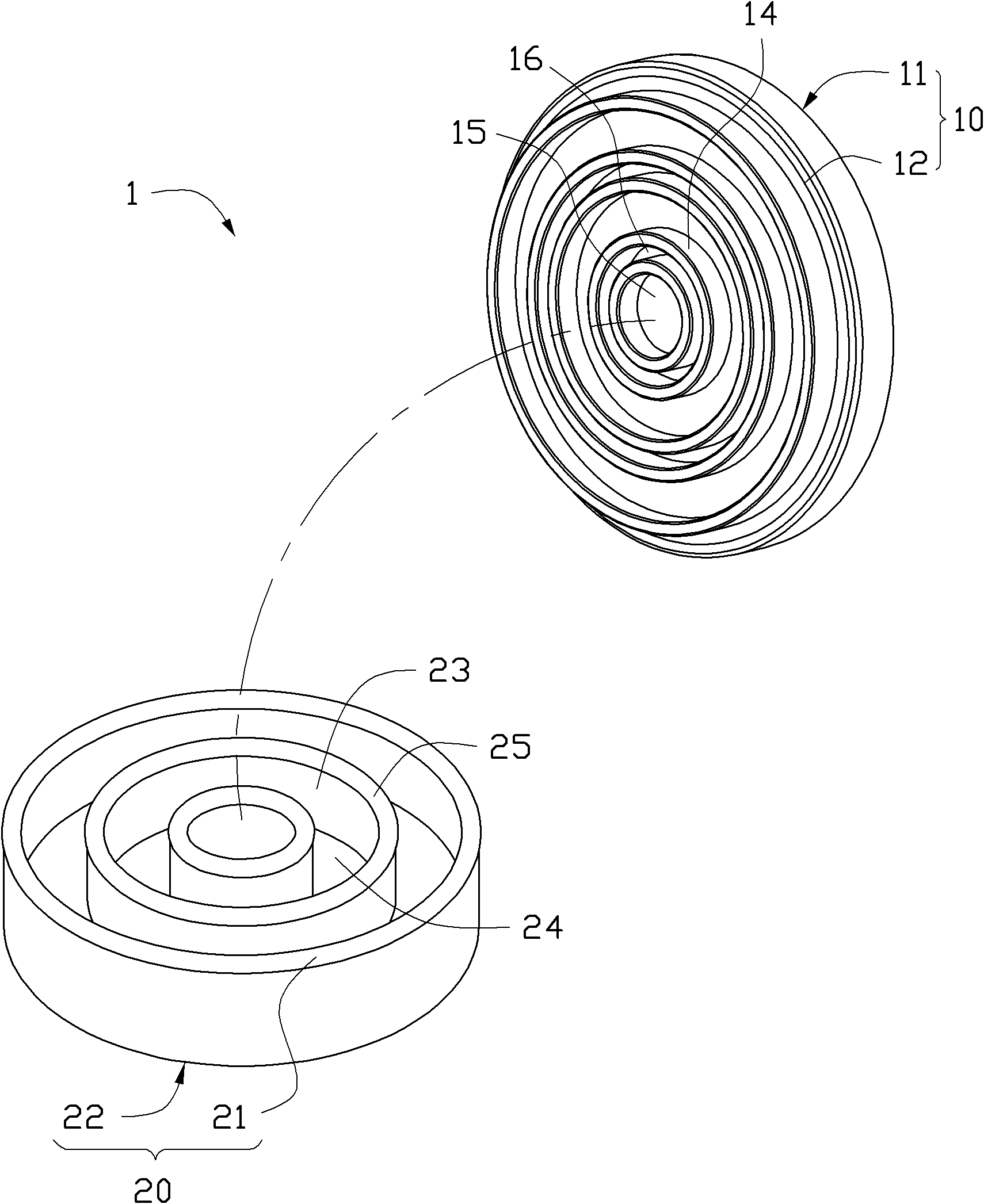

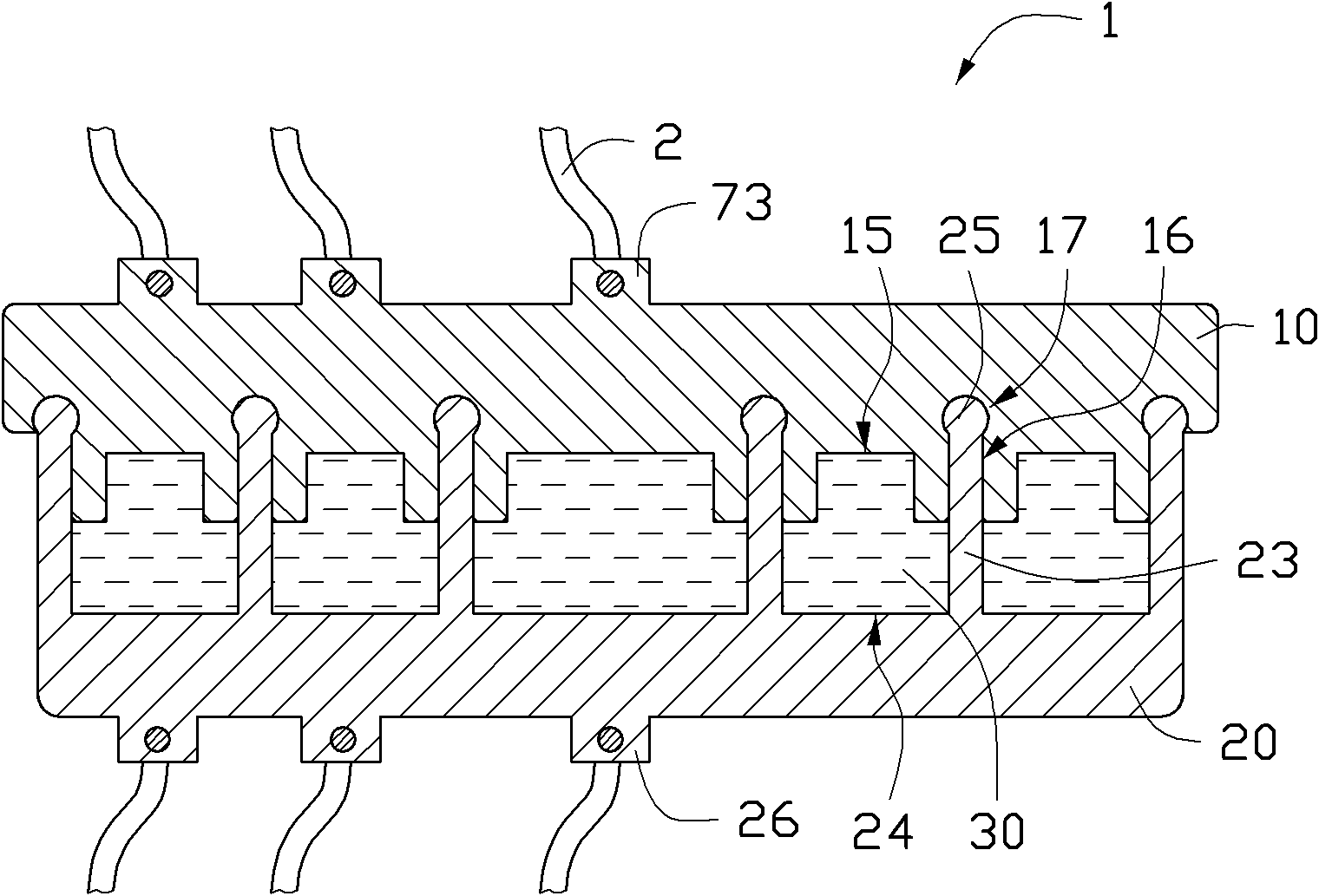

[0013] Please also refer to figure 2 , which is an exploded view of the rotary connection device 1 . The first rotating part 10 includes a first end surface 11 and a second end surface 12 opposite to each other. A plurality of conductive columns 13 are disposed on the first end surface 11 , and the plurality of conductive columns 13 are located in different radius areas relative to the center of the first rotating portion 10 . In this embodiment, the number of the conductive pillars 13 is three. A plurality of fixing portions 14 are disposed on the second end surface 12 . The fixing portions 14 are ring-shaped, and each bottom portion forms a conductive portion 15 . In this embodiment, the plurality of fixing portions 14 are concentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com