Method for judging pass/fail of bonding, apparatus for judging pass/fail of bonding, and bonding apparatus

A technology of a welding device and a judging method, which is applied to welding equipment, non-electric welding equipment, electrical components, etc., can solve problems such as failure to find defective products, deterioration of product yield, and failure to implement visual inspection procedures for welding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

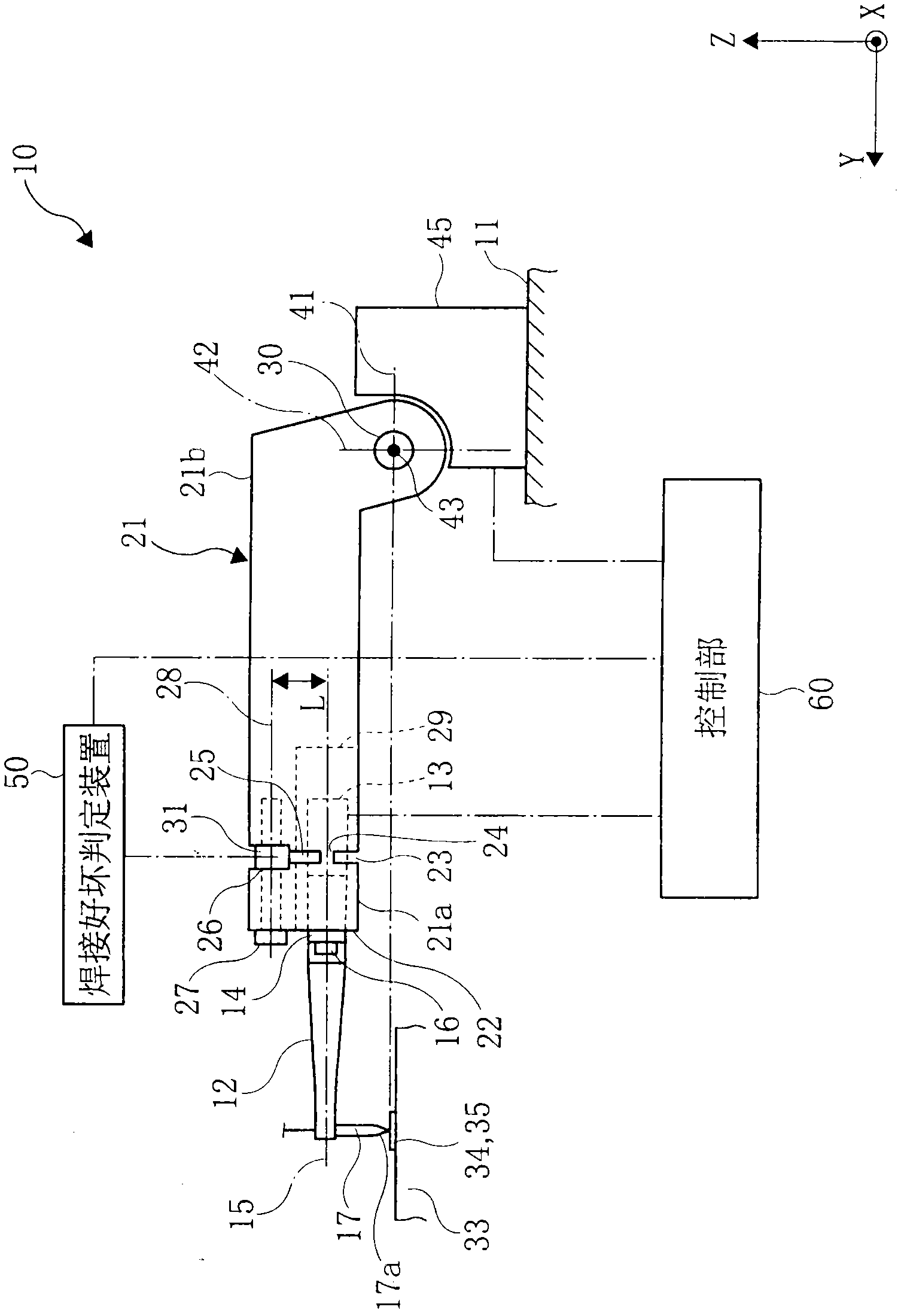

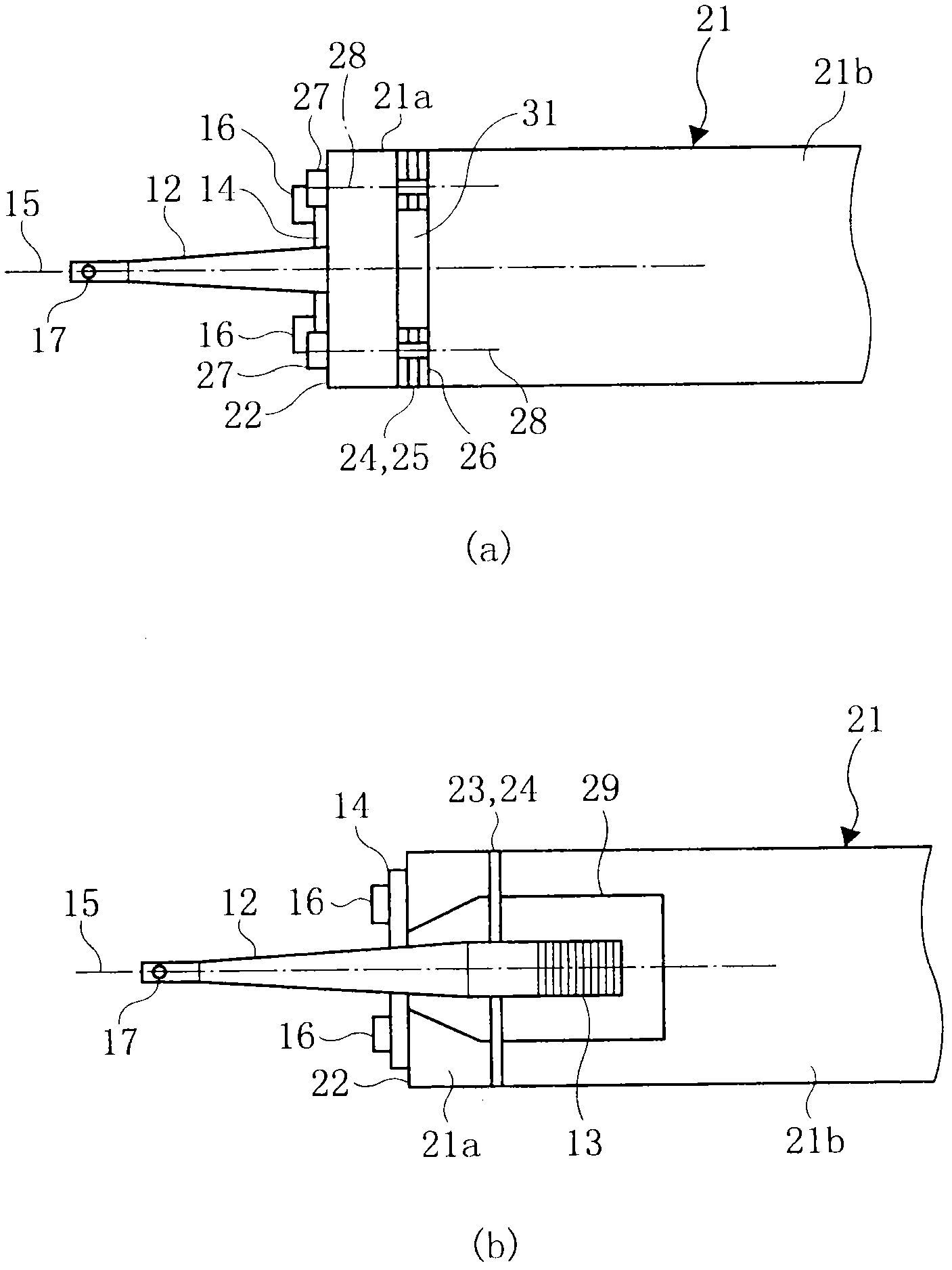

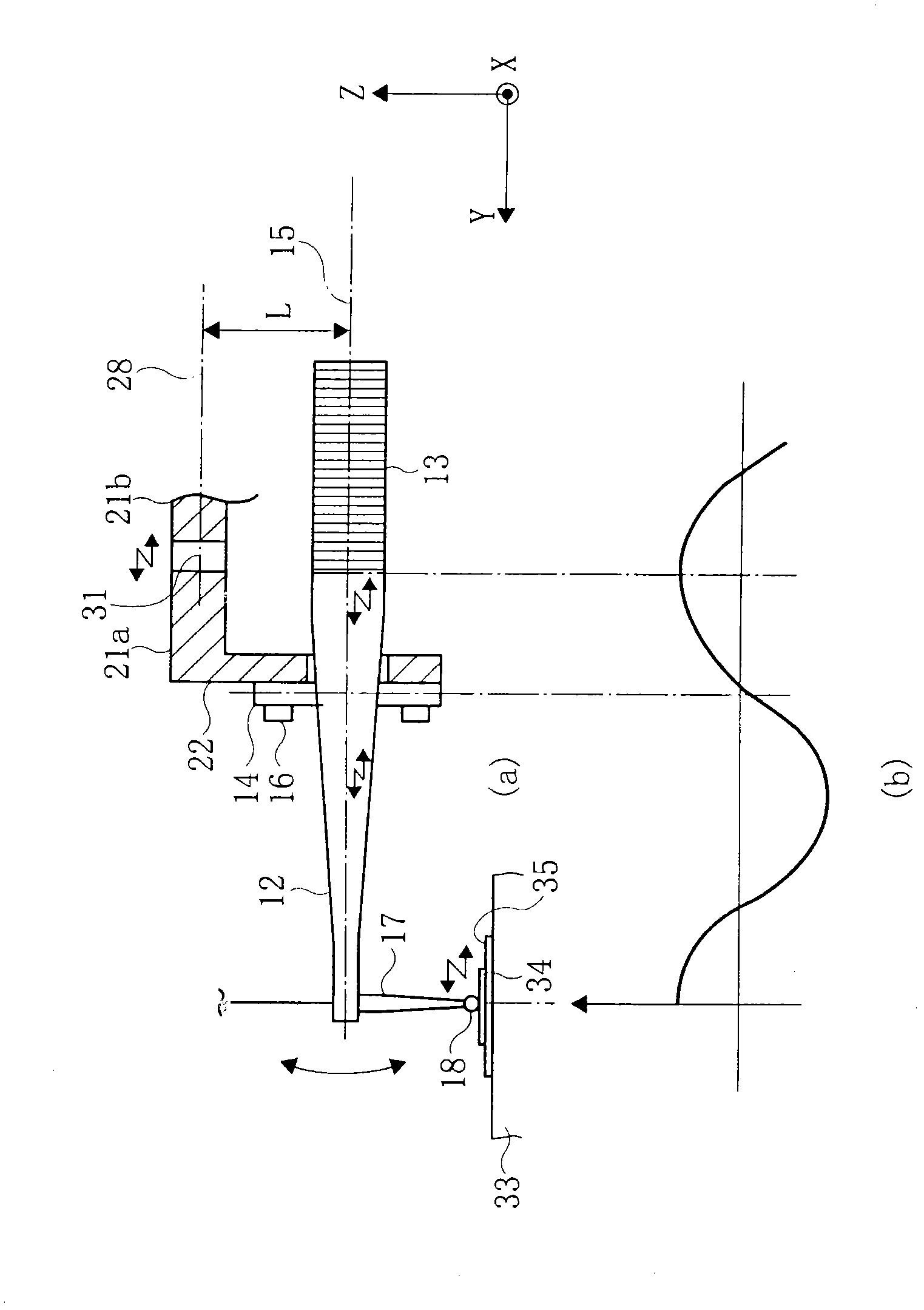

[0085] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 As shown, the lead wire bonding device 10 equipped with the bonding quality judging device of this embodiment includes a bonding head 11 as a base portion, an ultrasonic vibrator 13, an ultrasonic mold 12, a capillary 17 as a welding tool, and a flange on the ultrasonic mold 12. 14. A welding arm 21, a load sensor 31, a drive motor 45, a control unit 60, and a welding table 33 for absorbing and fixing a semiconductor chip 34 and a substrate 35 as welding objects.

[0086] A driving motor 45 for driving the welding arm 21 to rotate is provided on the welding head 11 . The ultrasonic vibrator 13 is formed by stacking a plurality of piezoelectric elements, and is mounted on the rear end side of the ultrasonic mold 12 . Also, a capillary 17 is attached to the tip of the ultrasonic mold 12 . The flange 14 is provided at a position to be a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com