Automatic detection control device for heavy rammer

An automatic detection and control device technology, applied in hoisting devices, clockwork mechanisms, roads, etc., can solve problems affecting the working efficiency of dynamic compaction machines, cumbersome operation methods, and increased operating costs, so as to save manpower and material costs, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

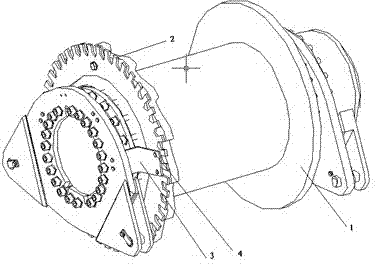

[0013] In order to realize that the dynamic tamping machine works in the non-decoupling mode, it is necessary to monitor the length of the steel wire rope in real time, and to perform timely automatic braking when the length is set. figure 1 It is a structural schematic diagram of the automatic detection control device of the dynamic compaction machine of the present invention. It can be seen from the figure that the automatic detection control device of the dynamic compaction machine in the present invention includes a high-frequency detection proximity switch (not shown in the figure), a gear ring 2 and a controller (not shown in the figure). Wherein, the gear ring 2 is installed on the side of the hoist drum 1, and the high-frequency detection proximity switch is installed on the outside of the drum 1, and is close to the gear ring 2, so as to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com