Electronic component mounting device

A technology for installing electronic components and electronic components, which is applied in the direction of electrical components, electrical components, etc., can solve problems such as difficulty in preventing misinstallation, and achieve the effects of avoiding installation actions, realizing rapidity, and realizing installation work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

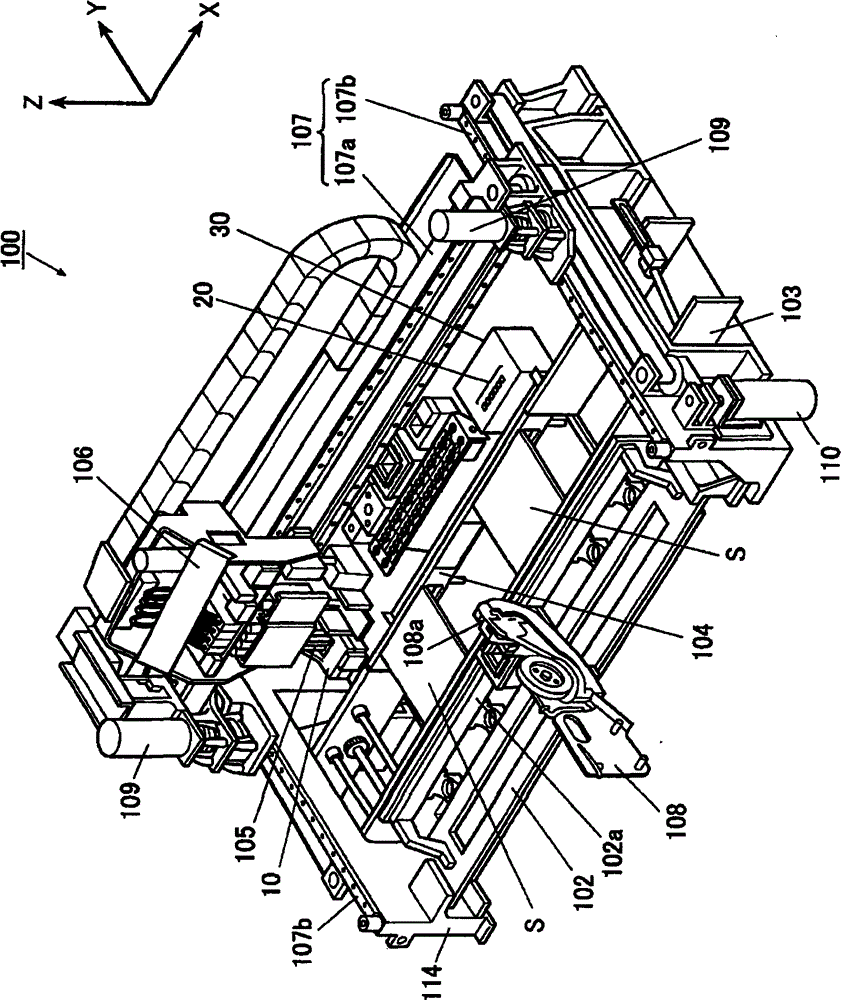

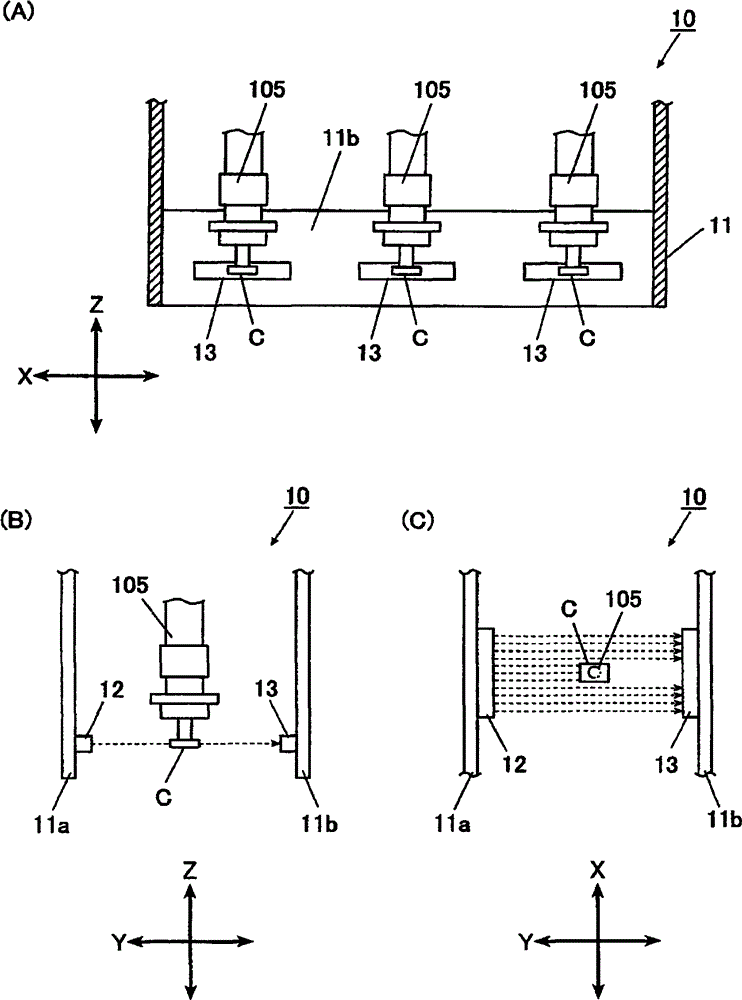

[0047] based on Figure 1 to Figure 7 , to describe embodiments of the invention. figure 1 It is a perspective view of the electronic component mounting apparatus 100 which concerns on this embodiment. Hereinafter, as shown in the drawing, two directions perpendicular to each other on a horizontal plane are referred to as an X-axis direction and a Y-axis direction, respectively, and a vertical direction perpendicular to them is referred to as a Z-axis direction.

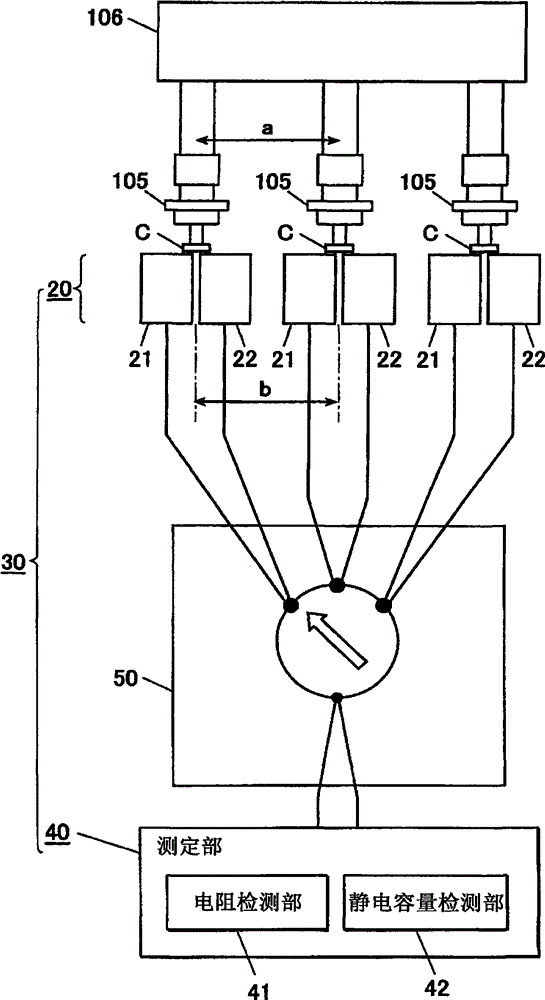

[0048]The electronic component mounting apparatus 100 mounts various electronic components C on the substrate S, such as figure 1 As shown, there is: a component supply part, which is composed of a feeder storage part 102 as a setting part, and the feeder storage part 102 holds a plurality of them in parallel (in figure 1 Only one is shown in the figure) an electronic component feeder 108 as a component supply device, which supplies electronic components C to be mounted; a substrate conveying unit 103, which convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com