Radiating module combined in interference fit

A heat-dissipating module and tight-fitting technology, used in indirect heat exchangers, lighting and heating equipment, instruments, etc., can solve the problems of poor product transfer efficiency, non-ideal, loose displacement of the heat-absorbing end of the heat-conducting pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

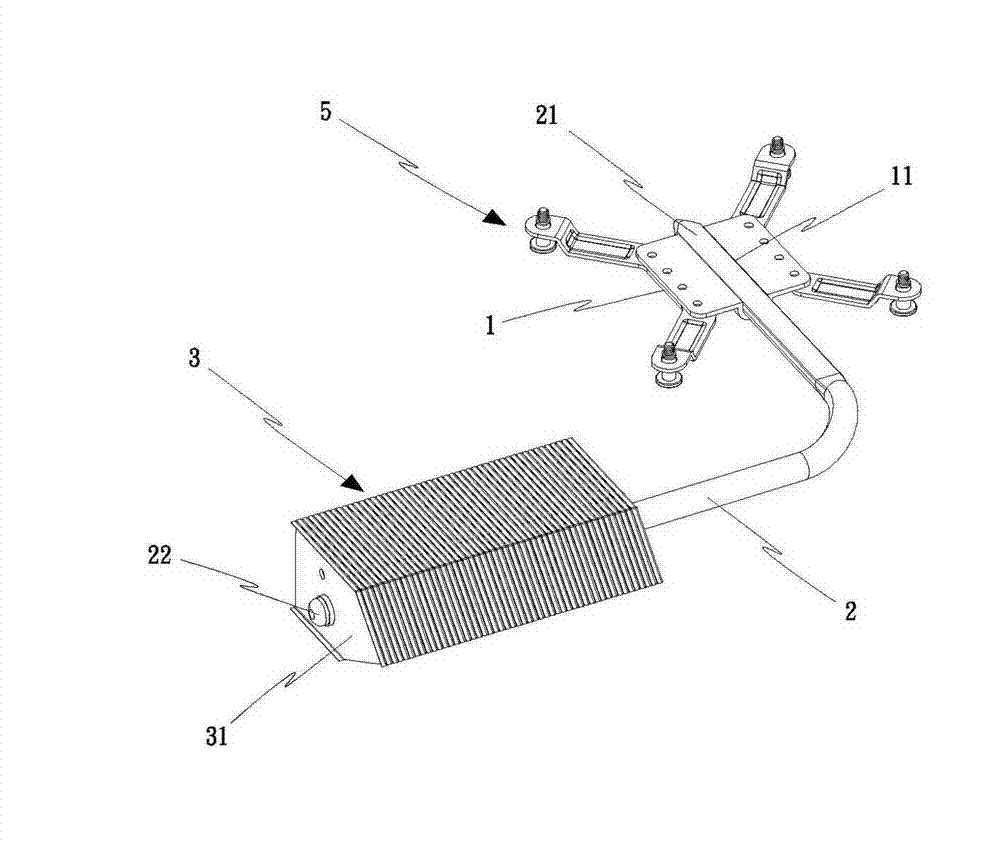

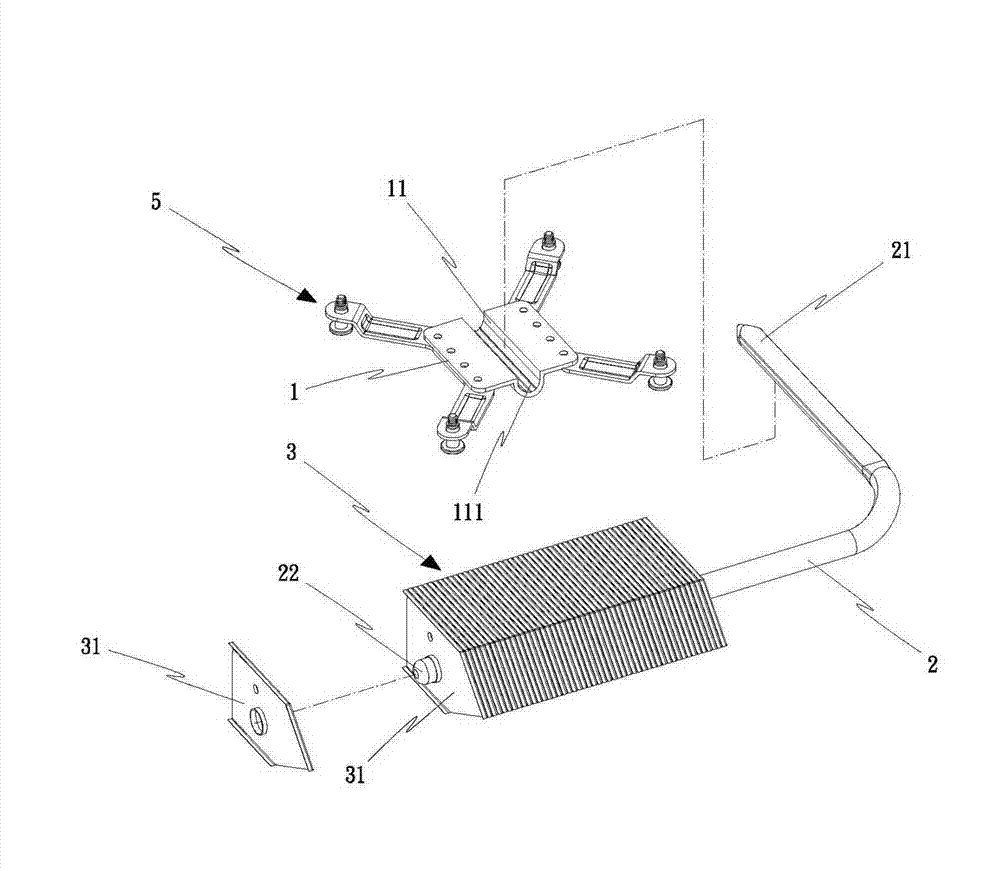

[0047] Such as figure 1 , 2 As shown, it is the first embodiment of the "tight fit combined heat dissipation module" of the present invention, which includes: a sheet-type heat conduction base 1, a heat conduction pipe 2 and a heat dissipation fin group 3, wherein:

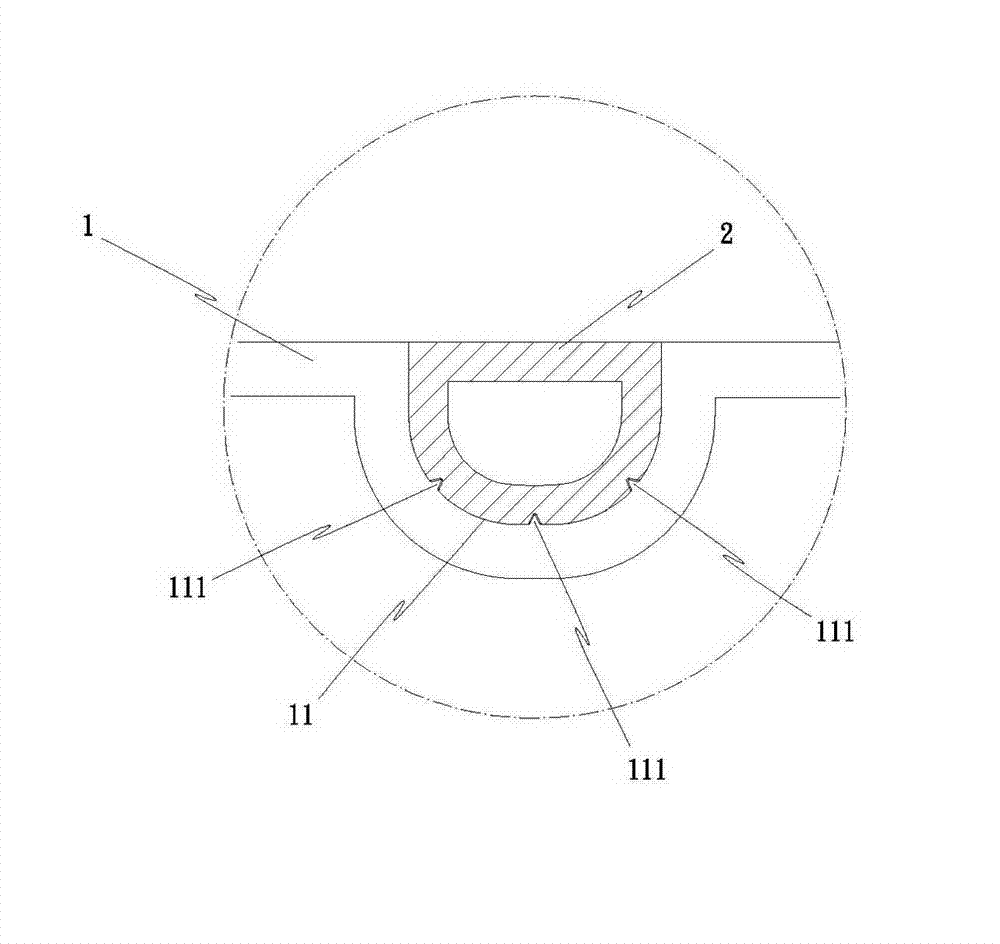

[0048] The sheet-type heat-conducting base 1 is made of a sheet for easy formation of a groove 11 that can match the heat-absorbing end 21 of the heat-conducting tube 2 (such as figure 2 ), the inner surface of the groove 11 is provided with more than one locking protrusion 111, as shown in the figure, it is implemented as a plurality of strip-shaped locking protrusions 111;

[0049] The heat pipe 2 has a heat-absorbing end 21 and a heat-dissipating end 22. The heat-absorbing end 21 is flatly embedded in the groove 11 of the heat-conducting base 1, and forms a relatively matchin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap