Universal hinge type bellow expansion joint

A technology of corrugated expansion joints and universal hinges, which is applied in the field of expansion joints, can solve the problems of large installation space, larger dimensions and weight of universal hinge expansion joints, difficulties in processing and production, etc., and achieve reduced dimensions and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the drawings and embodiments.

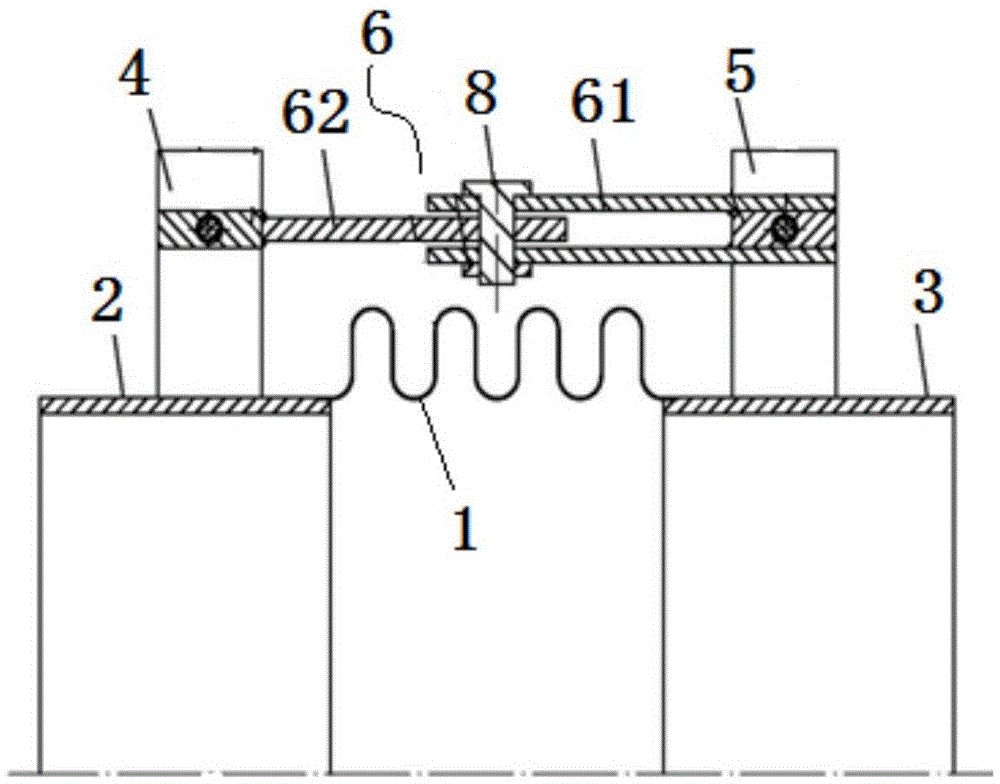

[0012] Such as figure 1 As shown, the present invention includes a corrugated pipe 1 with open ends, and two ends of the corrugated pipe 1 are respectively fastened and connected to an end pipe 2, 3 communicating with the corrugated pipe 1. A first bracket 4 is fastened to the end tube 2, and a second bracket 5 opposite to the first bracket 4 is fastened to the end tube 3. A hinge mechanism 6 is jointly supported between the first bracket 4 and the second bracket 5. The hinge mechanism 6 includes a hinge plate 62 with one end rotatably connected with the first bracket 4 and a hinge plate 61 with one end rotatably connected with the second bracket 5, and the other end of the hinge plate 62 is hinged with the other end of the hinge plate 61.

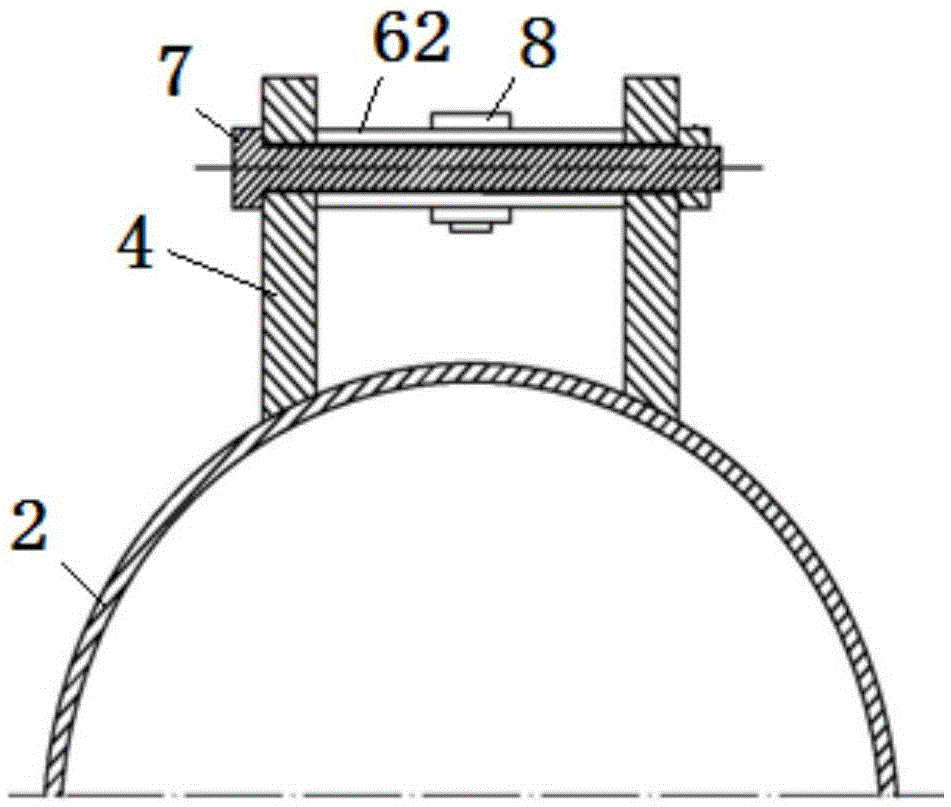

[0013] In the above embodiment, such as figure 2 As shown, one end of the hinge plate 62 can be rotatably connected to the first...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap