Assembly type fishpond

A prefabricated, fish pond technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of difficult demolition, long construction period of cast-in-place structure, etc., to reduce mold cost, reduce weight and external dimensions, and reduce damage the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

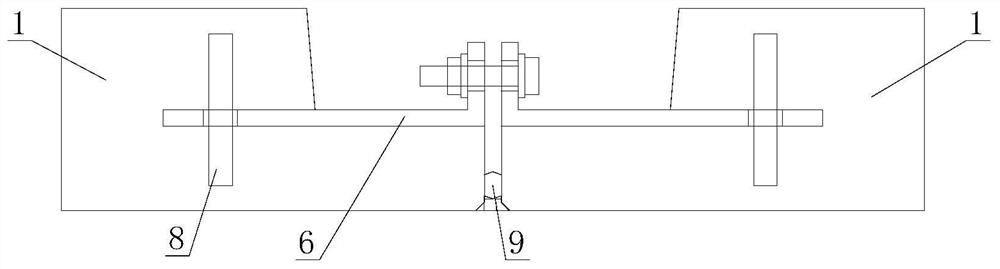

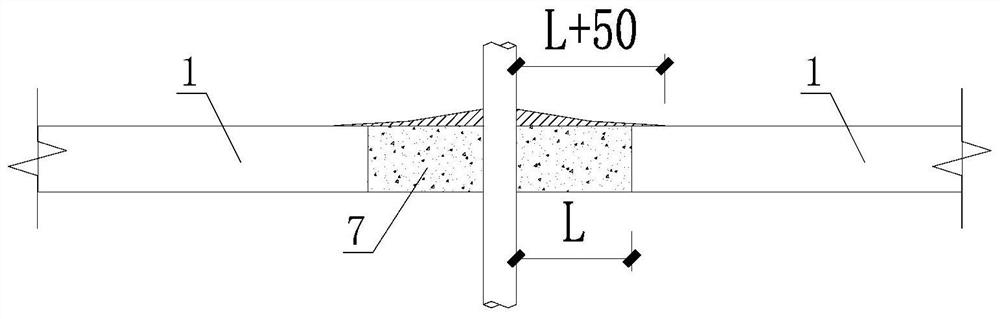

[0029] Such as Figure 1-3 As shown, an assembled fish pond includes a concrete fish pond component 1, and several concrete fish pond components 1 are combined and spliced to form a fish pond body, and two concrete fish pond components 1 are connected by a connecting mechanism, and the connecting mechanism includes a The L-shaped steel plate 6 in the concrete fish pond component 1, said L-shaped steel plate 6 one end (the long side of L-shaped steel plate) is embedded in the concrete fish pond component 1, the other end of said L-shaped steel plate 6 (the short end of L-shaped steel plate) Side) exposes the concrete fish pond component 1 to form a connecting portion, and the connecting portion is arranged in the groove 5, and the groove 5 is located on the side of the concrete fish pond component 1 away from the water; the connecting portion is provided with a bolt connection hole, connected , the bolts can directly pass through the bolt connection holes on the connecting po...

Embodiment 2

[0035] Based on the fish pond structure of the above-mentioned embodiment one, the manufacturing method of the assembled fish pond comprises the following steps:

[0036] 1) Prefabricated concrete fish pond component 1, using a mold to cast the precast concrete fish pond component 1, and pre-embed L-shaped steel plate 6 at the side of the concrete fish pond component 1, so that one end of the L-shaped steel plate 6 protrudes from the concrete fish pond component 1 to form a connection part ;

[0037] Concrete fishpond component 1 is made by reverse drilling process. This production method can precisely control the slope value of the bottom by setting the reverse slope on the bottom form, avoiding the problem of difficult control of the slope of the artificial closing surface, thus avoiding the problem of There is a height difference between adjacent component bases. In addition, the anti-beating process can also effectively ensure the flatness of the exposed surface of the pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap