Vehicle windshield wiper motor having multiple attachment points, and mounting structure for said motor

一种前窗玻璃、刮水器的技术,应用在车辆的清洗、车辆保养、机电装置等方向,能够解决增加电机制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

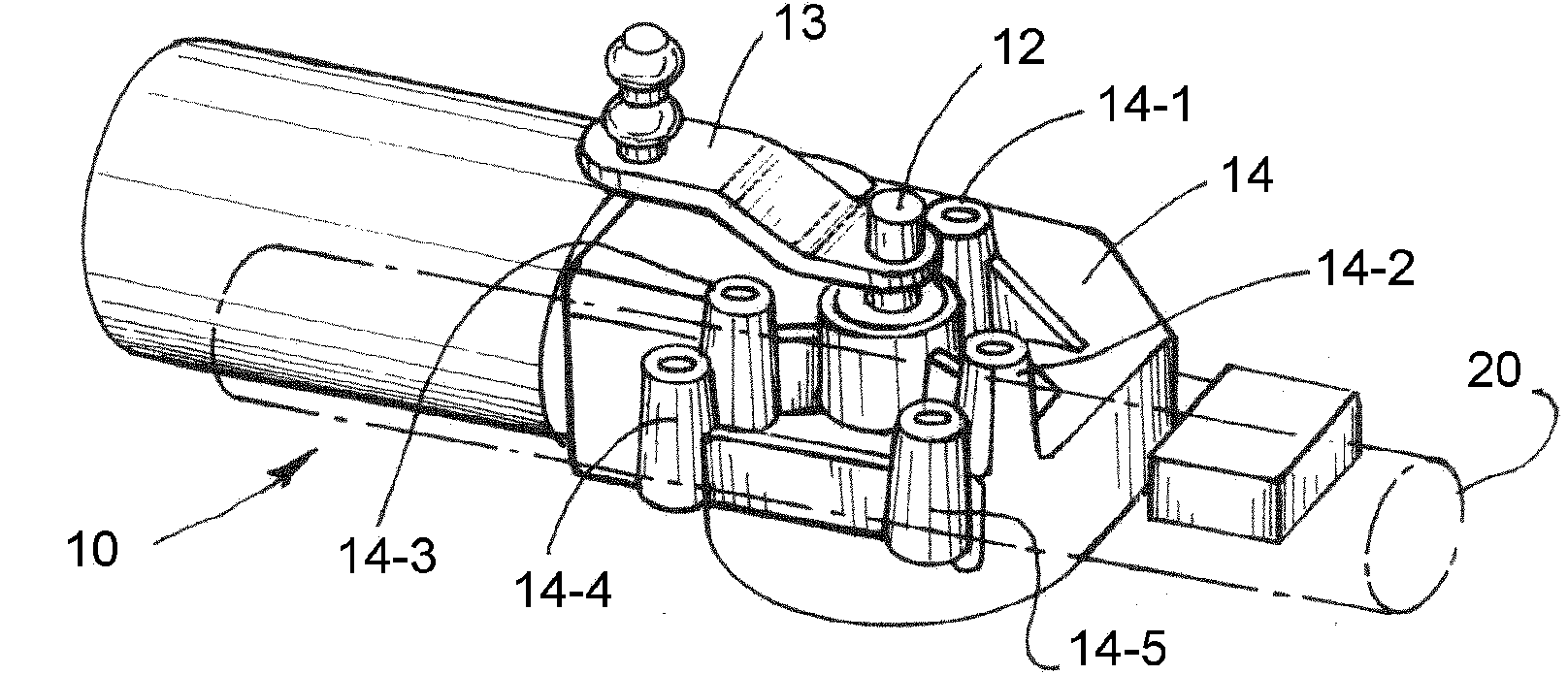

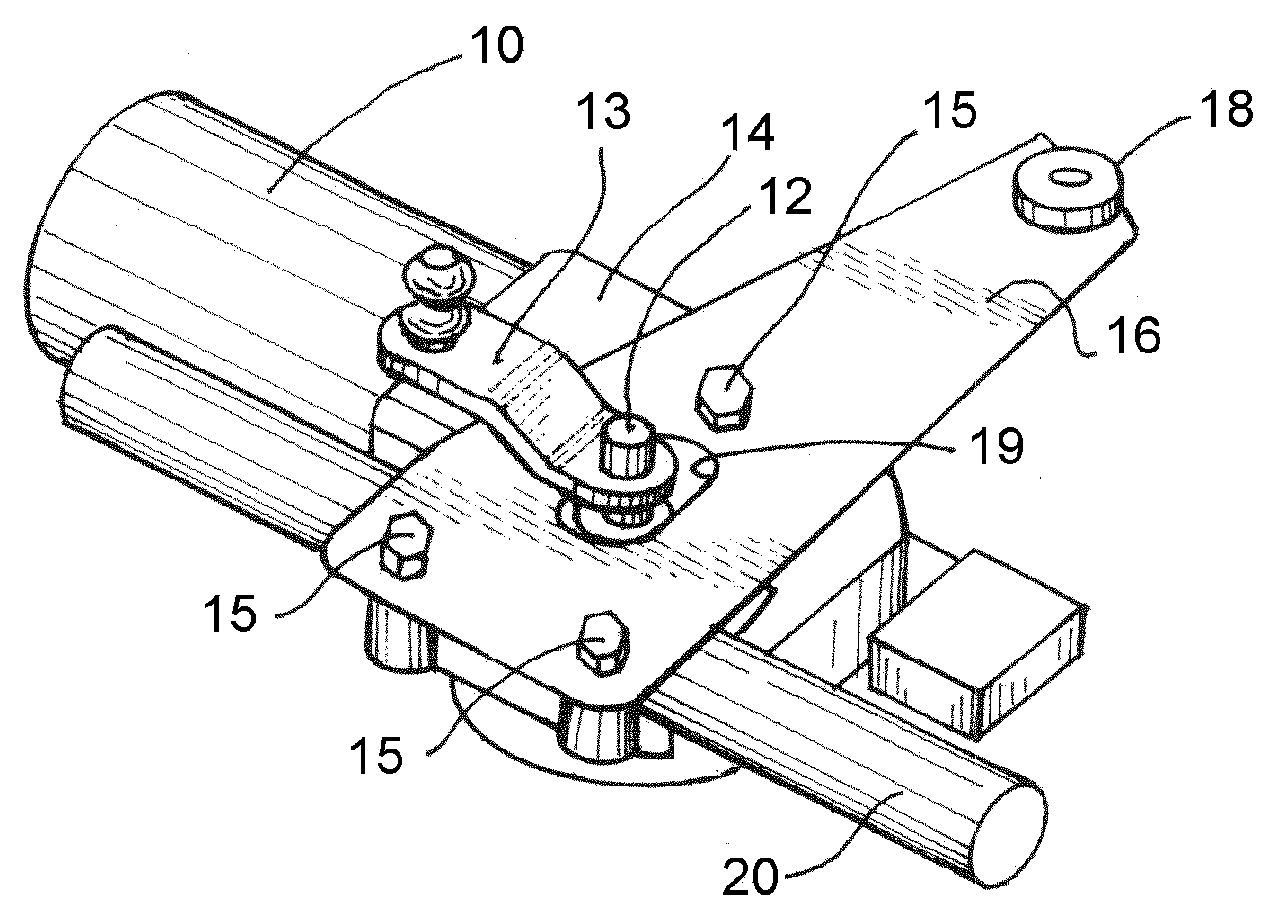

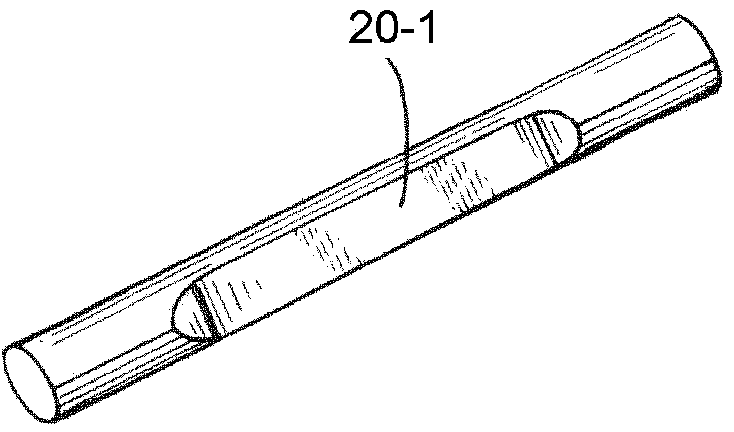

[0028] figure 1 A vehicle windshield wiper motor 10 is shown, comprising an output shaft 12 and equipped with means for fastening the motor to a tube 20 of a supporting structure.

[0029] This fastening device comprises fastening support 14 and mounting plate 16 ( figure 2 and 4 ).

[0030] exist figure 1 In the example shown, the mount 14 is provided with five fasteners 14-1 to 14-5 with parallel axes for fastening the mounting plate 16 thereto. These axes run perpendicular to the mounting plate when the mounting plate is fastened. Advantageously, these axes are parallel to the output shaft 12 of the motor.

[0031] In this example, the fastener is a hollow shaft with an internal thread so that a screw 15 can be screwed into the hollow shaft.

[0032] Three fasteners 14-1 to 14-3 form a first group. These fastening elements 14 - 1 , 14 - 2 , 14 - 3 are distributed around the output shaft 12 of the electric machine, for example at intervals of 120°.

[0033] Two othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com