Pellicle frame, pellicle and method for using pellicle frame

A surface film and component technology, which is applied in the photoengraving process of the pattern surface, the original for photomechanical processing, optics, etc., can solve the problems of increased mask weight, deflection, etc., and achieve remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~99、 comparative example 1~71

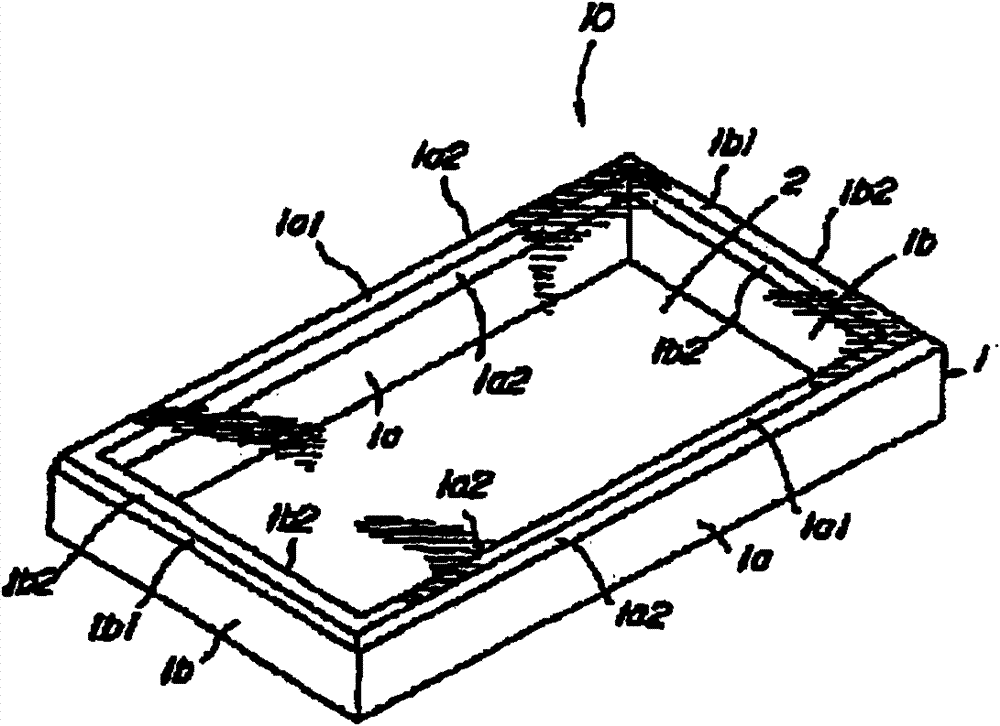

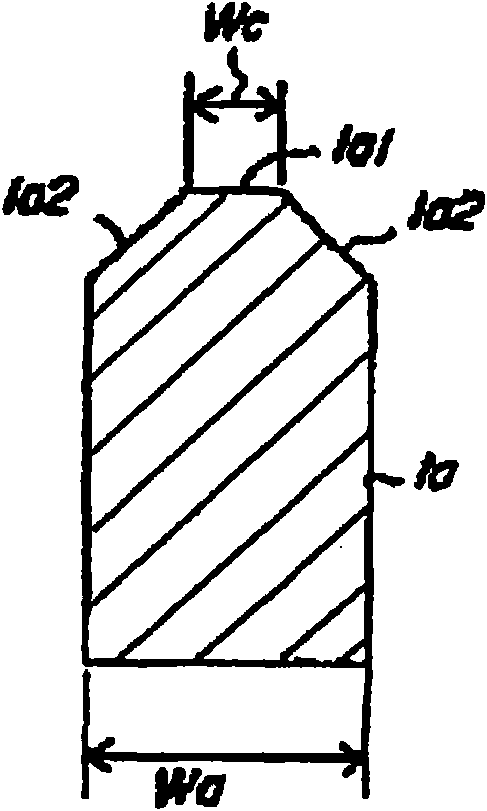

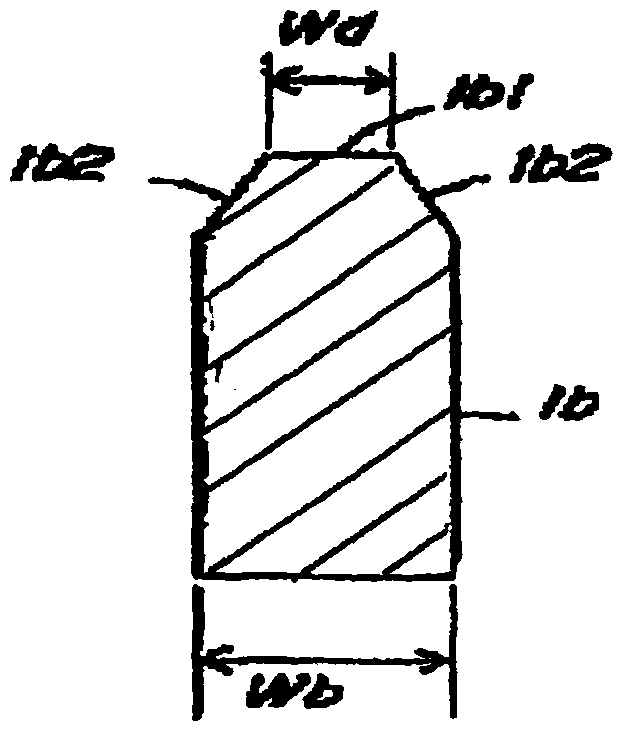

[0124] The length (La) of the long side 1a, the length (Lb) of the short side 1b, the inner area (effective area) of the frame 1, and the thickness of the frame 1 for super-large pellicle members are shown in Tables 1 to 9. . In addition, the width (Wa) of the long side 1a and the width (Wb) of the short side 1b of the surface film member frame are as shown in Table 1-Table 9.

[0125] In addition, aluminum alloy is used for the material of the frame of the surface film member, and the cross-sectional shape of the frame is rectangular. In addition, the surface film member frame used is a frame body without microcracks that has been subjected to black aluminum passivation treatment.

[0126] The performance of the actual surface film member was evaluated using the frame as described above.

[0127] The details are as follows.

[0128] As the surface film, a polymer solution of cellulose ester was coated on low-alkali glass, and the main film was formed by spin coating.

[0...

Embodiment 100~197、 comparative example 72~141

[0141] The length (La) of the long side 1a, the length (Lb) of the short side 1b, and the inner area (effective area) of the frame of the super-large pellicle member frame 1 used in Examples and Comparative Examples are shown in Tables 10 to 16. shown. Tables 10 to 16 also show the width (Wa) of the long side 1a, the width (Wb) of the short side 1b of the pellicle member frame, and the thickness of the pellicle member frame.

[0142] In addition, aluminum alloy is used for the material of the frame of the surface film member, and the cross-sectional shape of the frame is rectangular. In addition, the frame of the surface film member used was a frame without microcracks to which black passivated aluminum was applied.

[0143] The performance was actually evaluated using a frame for a surface film member having the above-mentioned specifications.

[0144] As the surface film, a polymer solution of cellulose ester was coated on low-alkali glass, and the main film was formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com