Floor finishing material

A decorative material and floor technology, which is used in aircraft floors, floor coverings, transportation and packaging, etc., can solve the problems of complex manufacturing processes, and achieve the effect of reduced processes and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

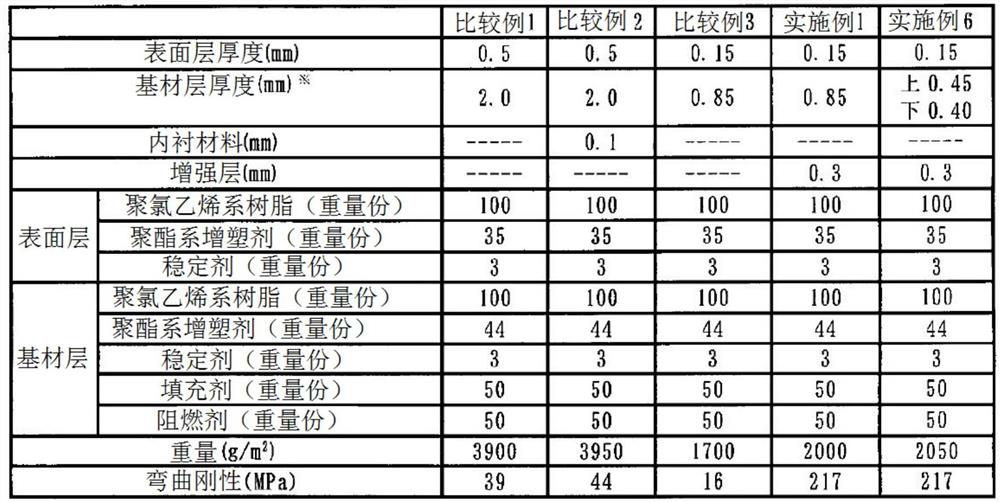

[0075] Hereinafter, the present invention will be described in detail with reference to examples. However, the present invention is not limited to the following examples.

[0076] Materials used in Examples and Comparative Examples are as follows.

[0077] Polyvinyl chloride resin: polyvinyl chloride polymerization degree 1000

[0078] Phthalate-based plasticizer: DOP (dioctyl phthalate)

[0079] Polyester-based plasticizer: adipic acid-based polyester plasticizer, viscosity (25°C) 150mPa·s

[0080] Phosphate-based plasticizer: TCP (tricresyl phosphate)

[0081] Stabilizer: barium zinc stabilizer

[0082] Filler: light calcium carbonate

[0083] Flame retardant: mixture of zinc hydroxystannate and molybdic acid compound (mixing ratio 3:2 (weight ratio))

[0084] Lining material: polyester woven fabric

[0085] Adhesive: vinyl chloride copolymer (vinyl chloride-vinyl acetate copolymer) emulsion

[0086] The reinforcement layers of Examples 1, 2, and 6 and Comparative Exam...

Embodiment 6

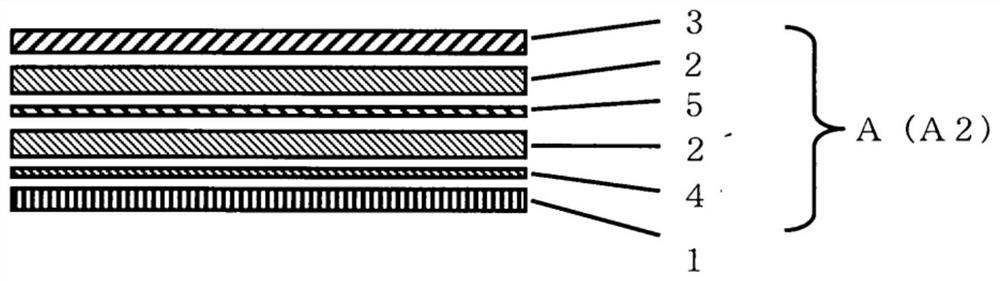

[0091] The second reinforcement layer of Example 6 is as follows.

[0092] The second reinforcement layer: glass woven fabric (twill), thickness 0.1mm

[0093] Yarn used Tex warp 34(g / 1000m) weft 69(g / 1000m)

[0094] Weaving density Warp yarn 10×2 / 25mm Weft yarn 10 / 25mm

Embodiment 1、6、 comparative example 1~3

[0096]

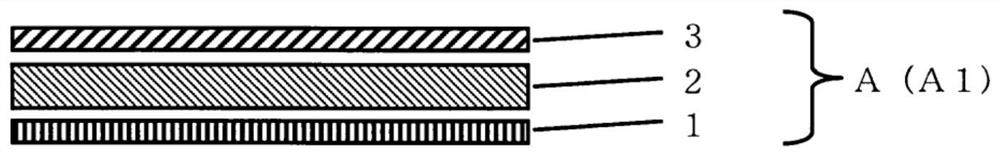

[0097] Based on the formulations in Table 1, the formulations for the surface layer and the substrate layer were kneaded separately, and the resulting compounds were formed into sheets for each layer using two rolls at 175°C. In addition, an adhesive was applied to one side of the reinforcement layer used in the examples by bar coating, and then heat-dried at 140° C. for 30 seconds to form an adhesive layer. And each obtained layer was laminated|stacked, it press-processed at 170 degreeC, and the floor finishing material shown in Table 1 was obtained. Here, having a lining material means that the layers are laminated in the order of lining material / base material layer / surface layer from below. Having a reinforcing layer means that the reinforcing layer / adhesive layer / substrate layer / surface layer are laminated in this order from below. Having a second reinforcing layer means that the layers are laminated in the order of reinforcing layer / adhesive layer / substrate la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com