Plating tank closed cover switch mechanism

A technology of cover switch and electroplating tank, applied in the field of tank cover switch mechanism, can solve the problems of polluting the environment, large gap between the tank cover and the slot, endangering the health of operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

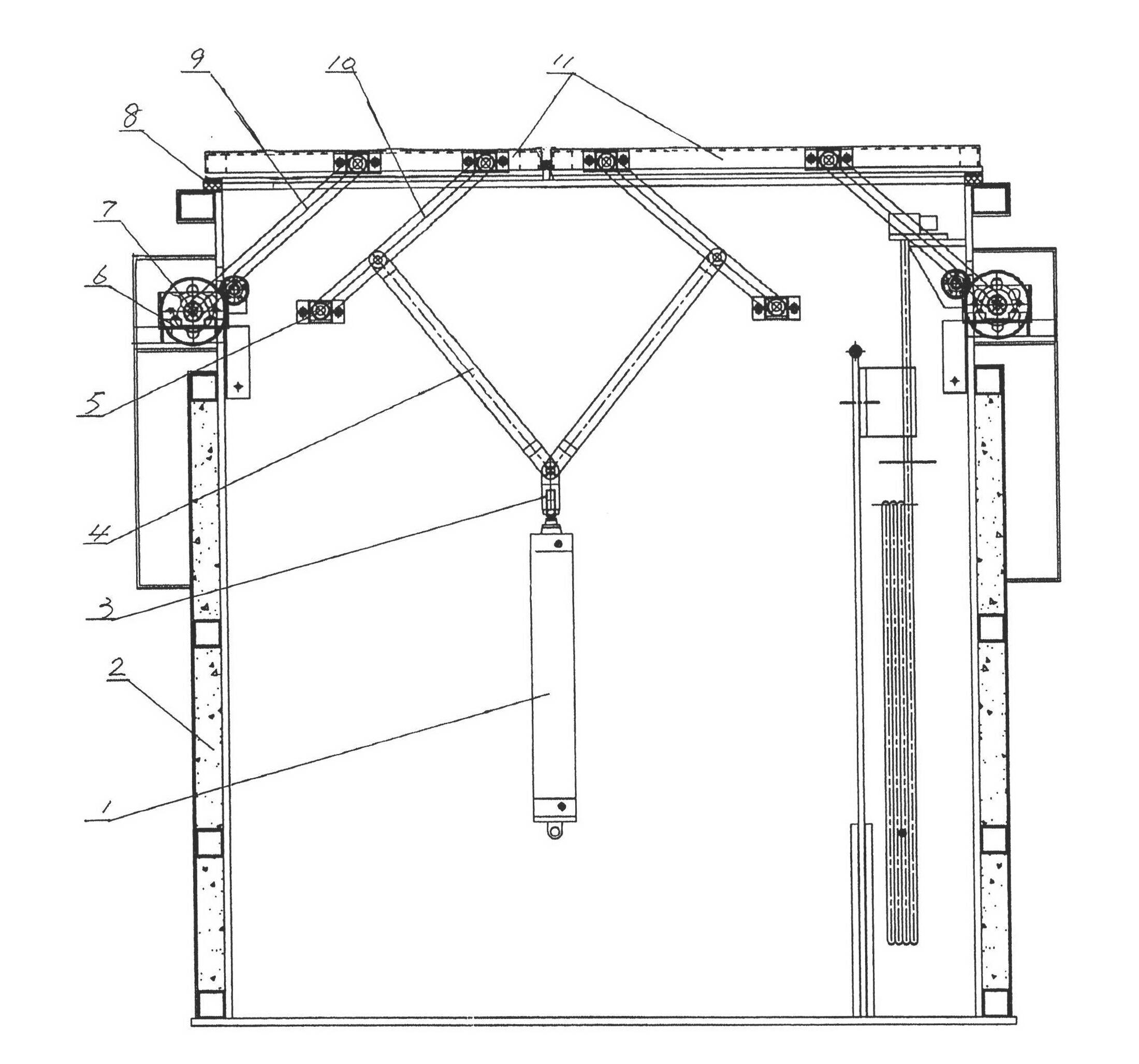

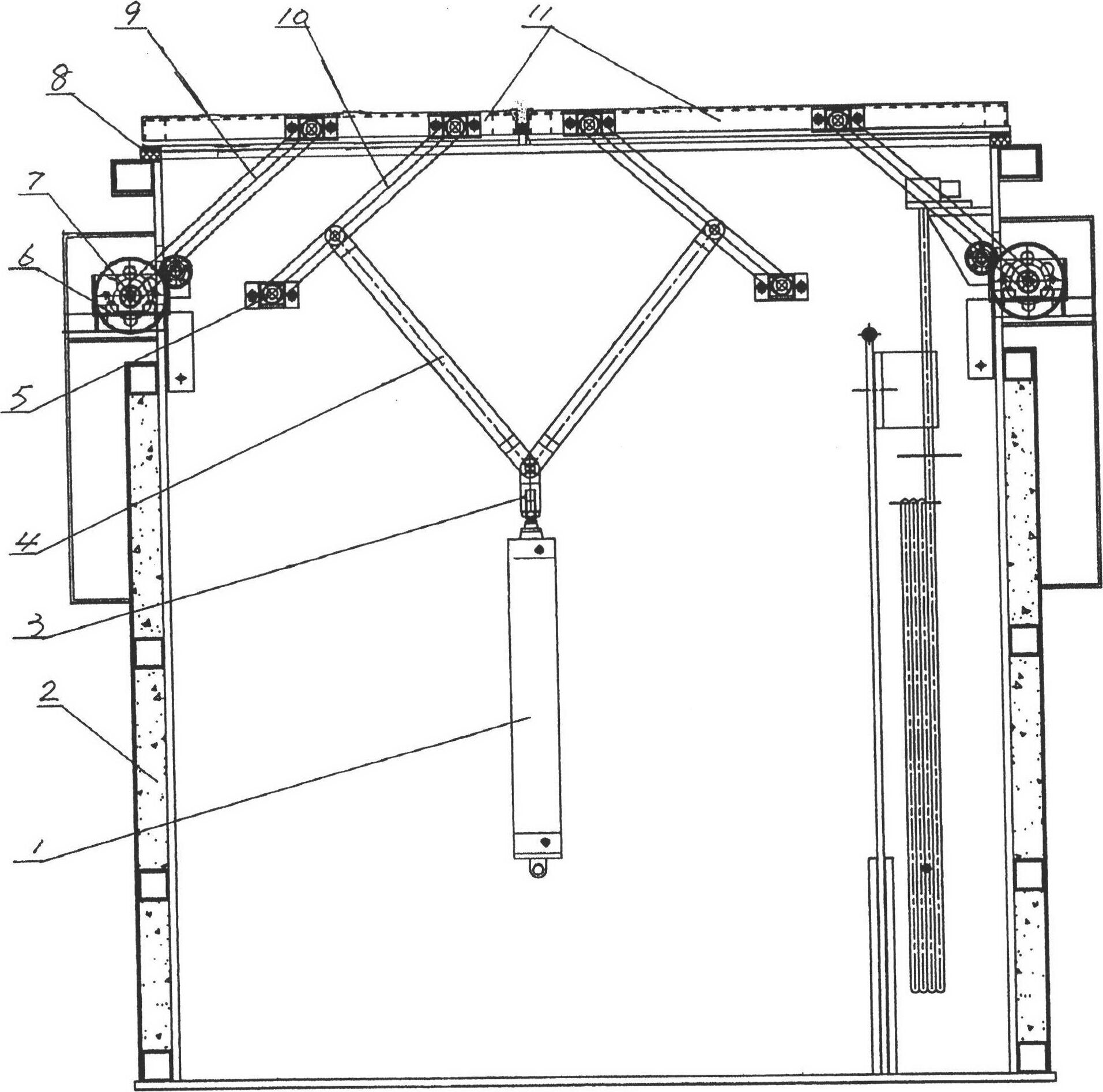

[0009] Such as figure 1 As shown, the electroplating tank airtight cover switch mechanism of the present invention includes a tank body 2 , the mouth of the tank body 2 is rectangular, and the mouth of the tank body 2 is provided with a tank cover, which is composed of two unit tank covers 11 . The lengths of the two unit slot covers 11 are equal and equal to the length of the slot. Two shaft seats 6 are arranged on the outer sides of the two long groove walls of the tank body 2, and all the shaft seats 6 are at the same height. A rotating shaft 7 is arranged between the two shaft seats 6 on the same groove wall, and the two ends of the rotating shaft are inserted into the corresponding shaft seats 6, so that the two rotating shafts 7 are arranged horizontally and at the same height. The groove walls at both ends of the tank body 2, that is, the two short groove walls, are provided with two short shafts 5, one end of the two short shafts is fixed on the corresponding groove w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com