Spindle drive

A technology of main shaft transmission and transmission device, applied in transmission device, gear transmission device, transportation and packaging, etc., can solve the problem of high cost of main shaft nut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

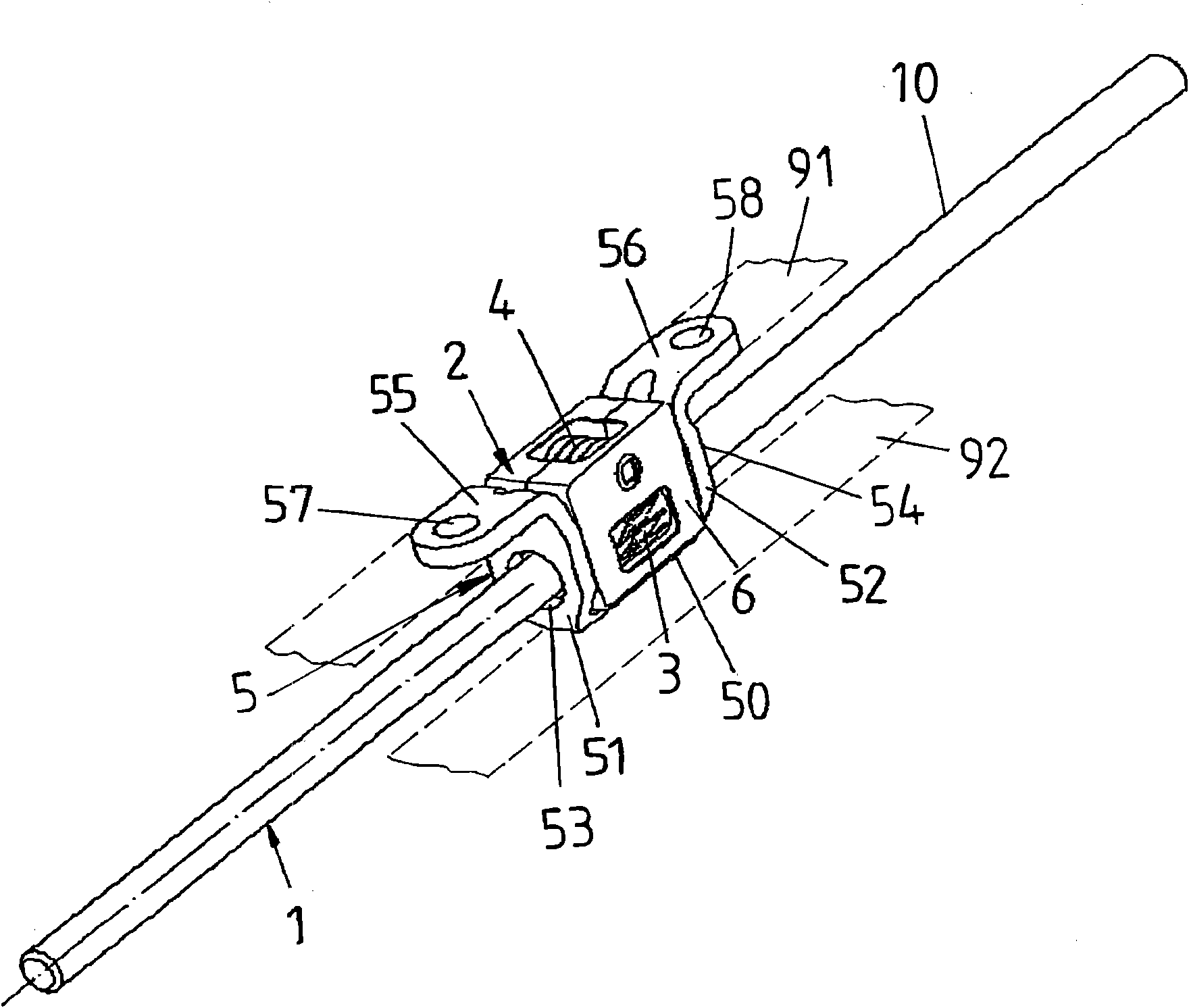

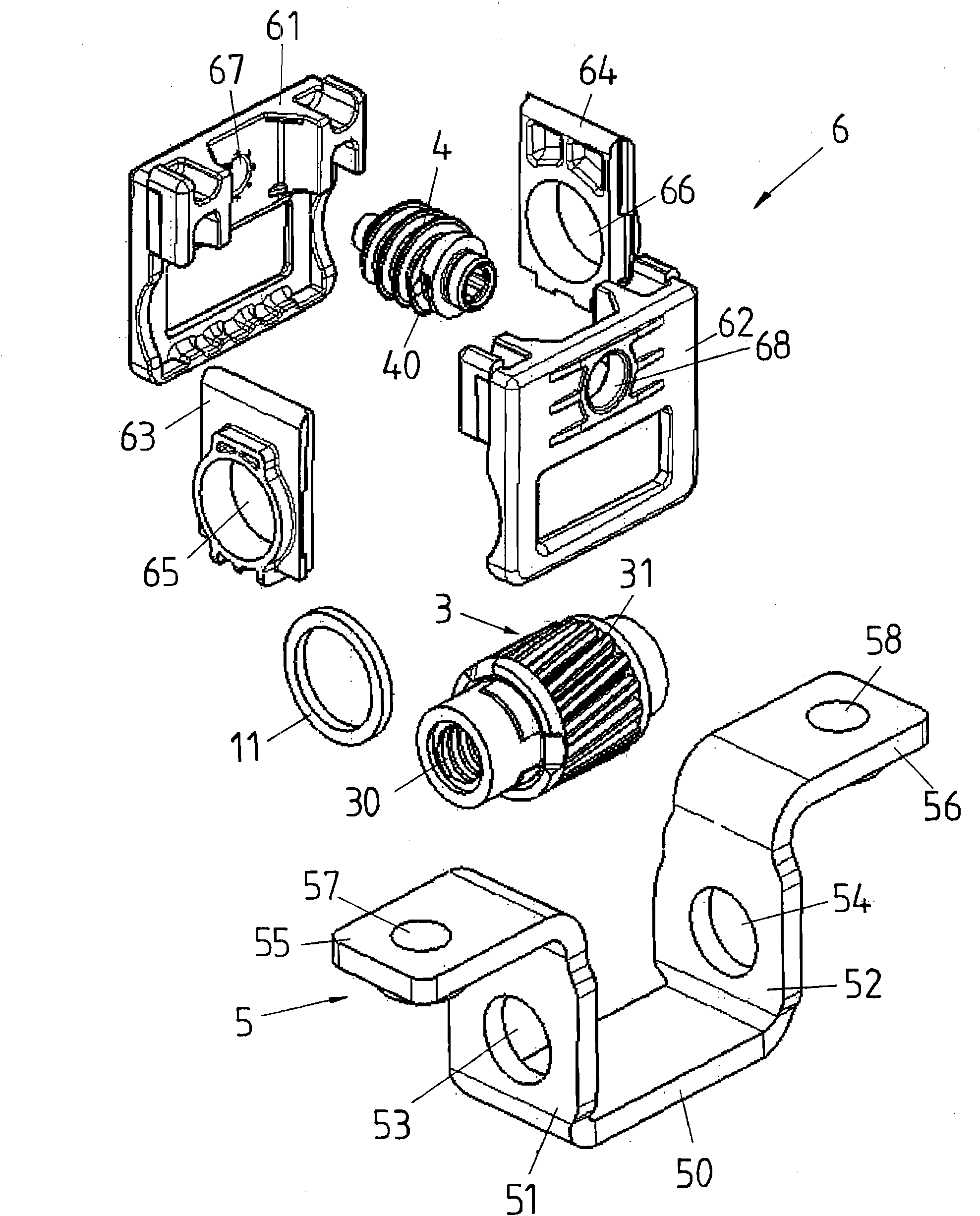

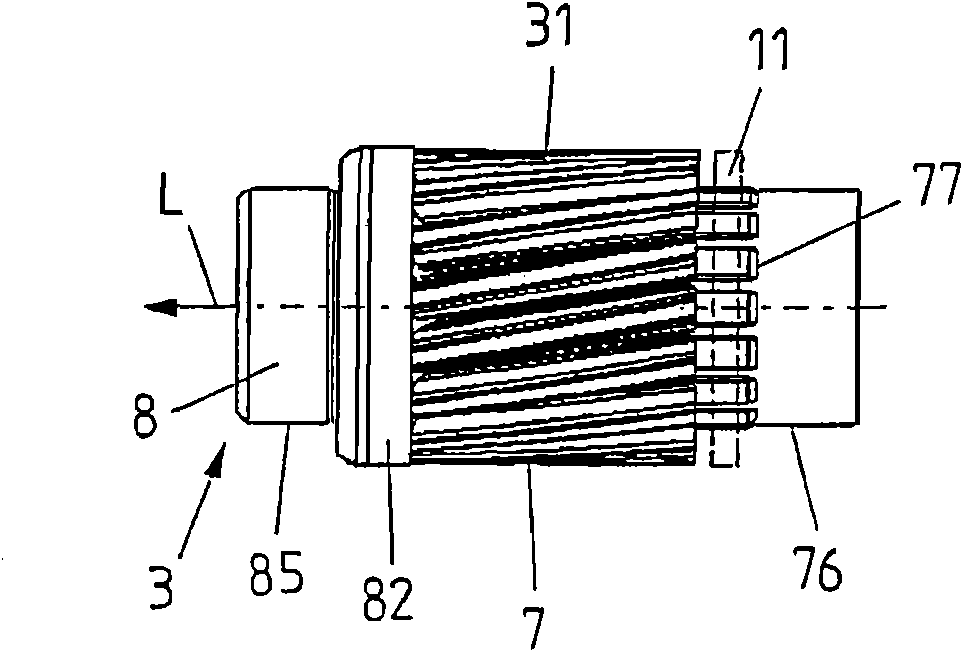

[0056] one in figure 1 The spindle drive shown in has a spindle 1 arranged (only schematically) on a fixed rail 92 of the body, which engages with an adjusting drive 2 which is connected to a (schematically shown) for the vehicle seat Shown) the adjustment rail 91 of the seat longitudinal adjustment device is connected, for example, the upper rail that is slidably installed on the fixed (lower) rail 92 of the vehicle body. The retaining angle 5 is used to fasten the adjusting gear 2 on the adjusting rail 91 and is preferably made of metal and in particular steel, it has a base body 50 and two side legs 51 , 52 in Through-holes 53 , 54 for the spindle 1 are provided in each case. From the two side legs 51, 52 of the holding angle 5 protrude respectively a fastening flange 55, 56, said fastening flange has fastening points 57, 58 in the form of fastening holes, by means of which fastening points the holding angle 5 is fixed on On the adjustment rail, the adjustment gear 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com