Automatic repair of flat, textured objects, such as wood panels having aesthetic reconstruction

A technology for automatic repair and surface texture, which is used in wood processing appliances, general control systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

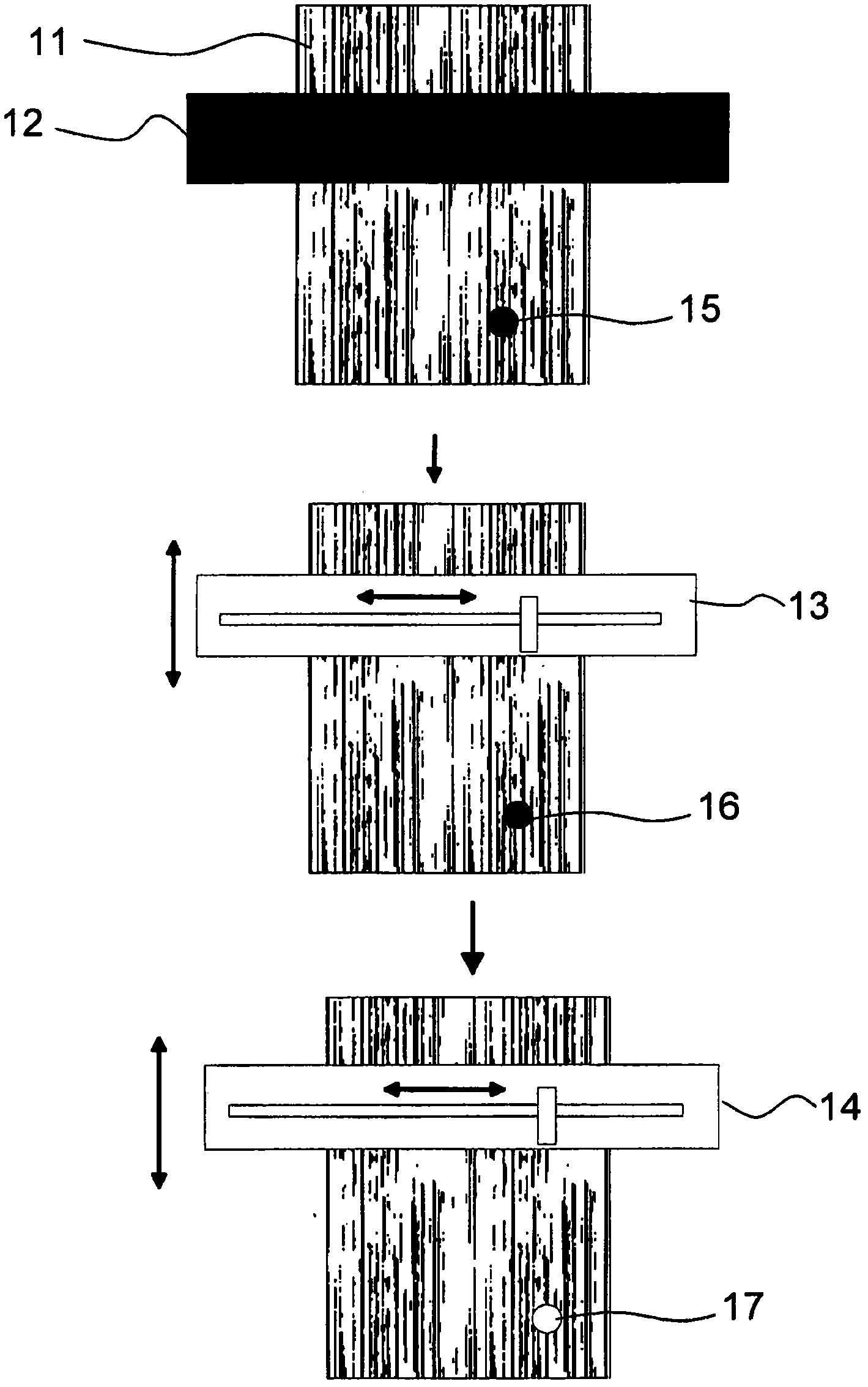

[0043] figure 1 A prior art automatic repairing device for panels with a natural wood surface 11 is shown in simplified form, comprising a black / white scanner 12 for identifying physical defects 15 and measuring their position, a for A first Cartesian XYZ robot 13 for moving a milling cutter to the defect 16 , a second Cartesian XYZ robot 14 for moving a filler injection tool to the milled defect 17 . With regard to the repairing step, a device of this type can also be used in the method according to the invention, or as a component of the device according to the invention.

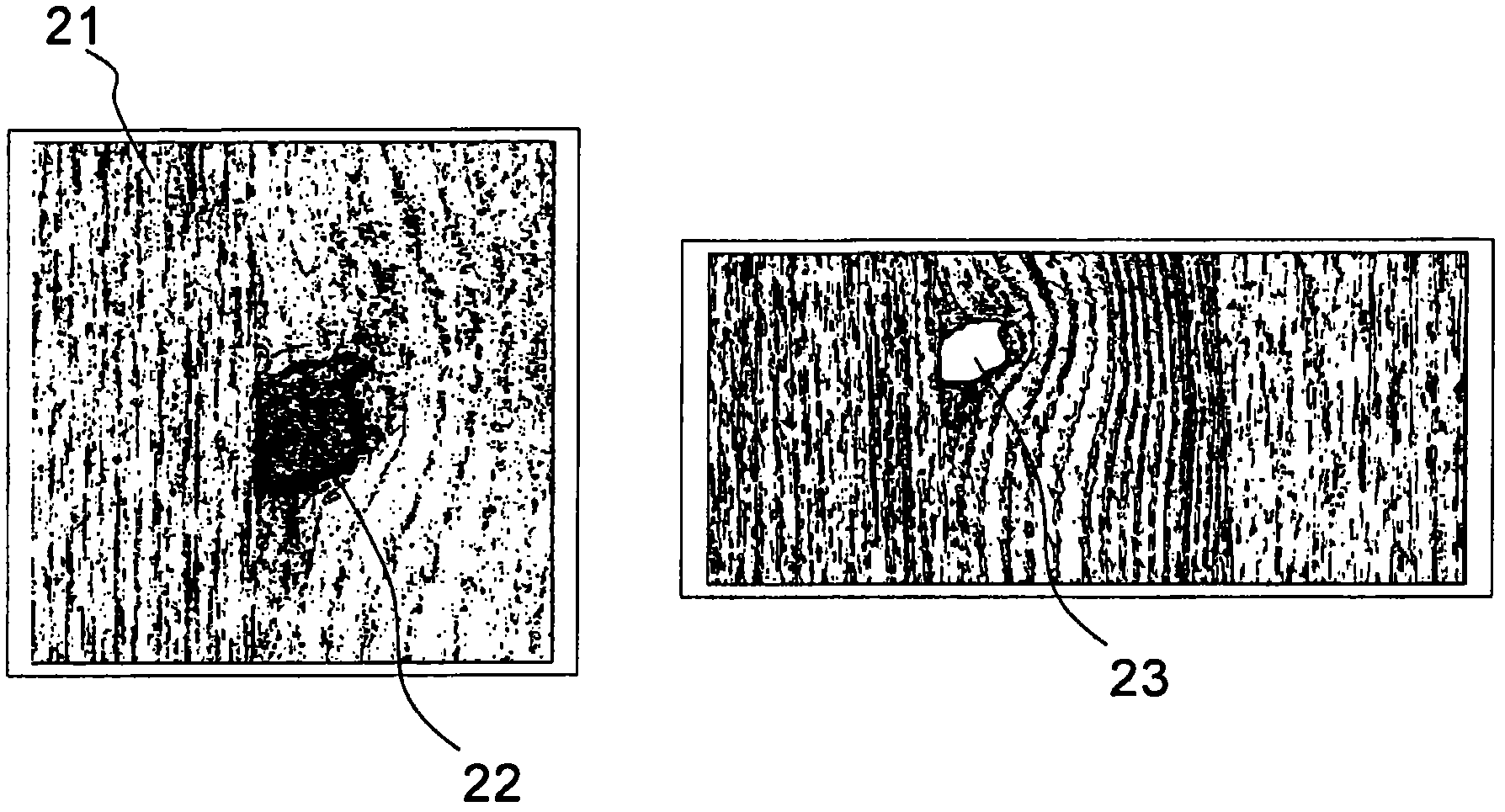

[0044] figure 2 A timber surface 21 with a decayed, missing knothole is shown before 22 and after 23 repair by caulking. Defects are visually conspicuous and objectionable due to the homogeneous, unpatterned filler of the repaired knotholes 23 , although the shade of the filler is well matched to the shade of the wood surface.

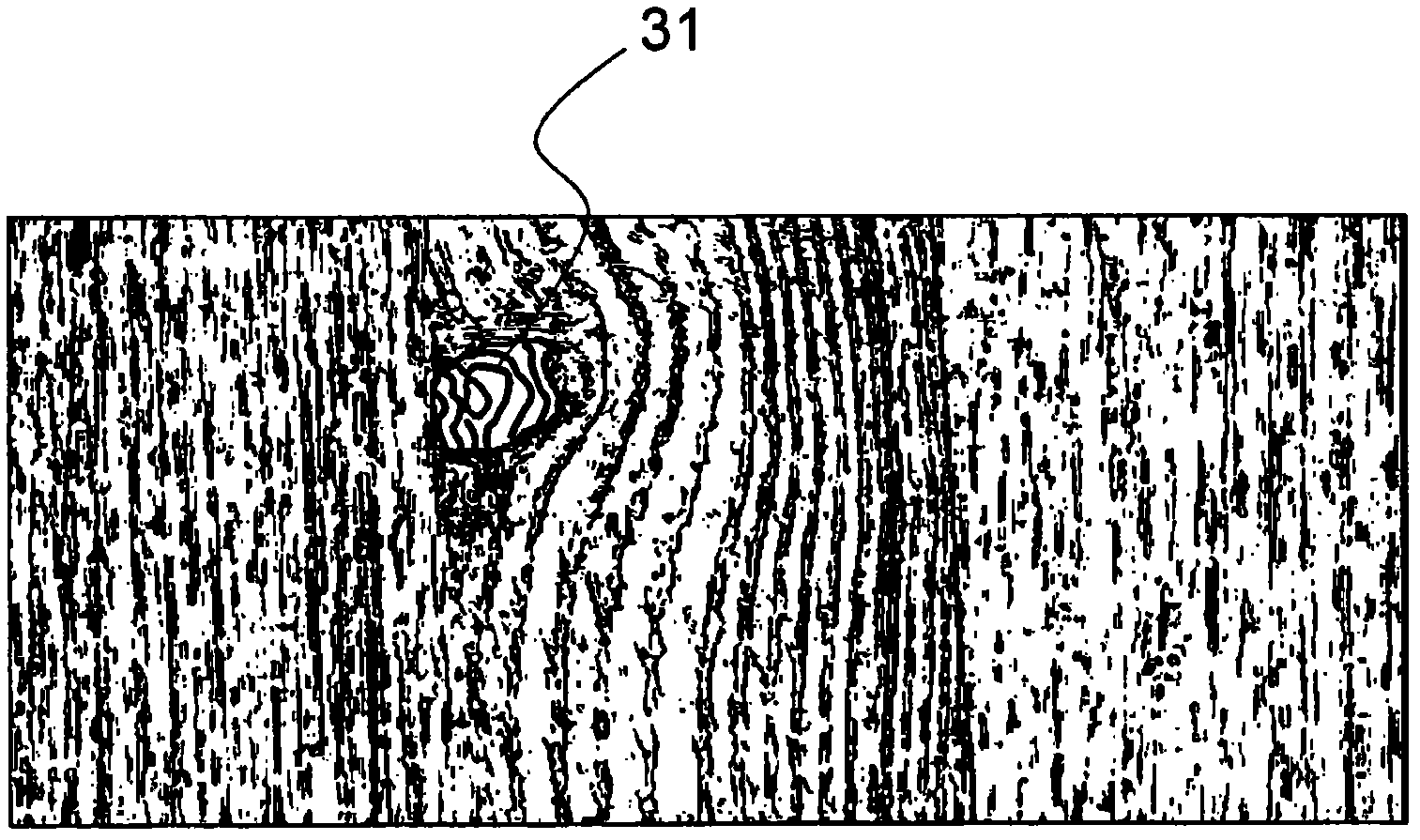

[0045] image 3 Defects are shown in simplified form as black / white line...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap