Vertical radiator shutter device

A louver device and radiator technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of convenient procurement and manufacturing, improving compressive and tensile bending stiffness, and improving bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

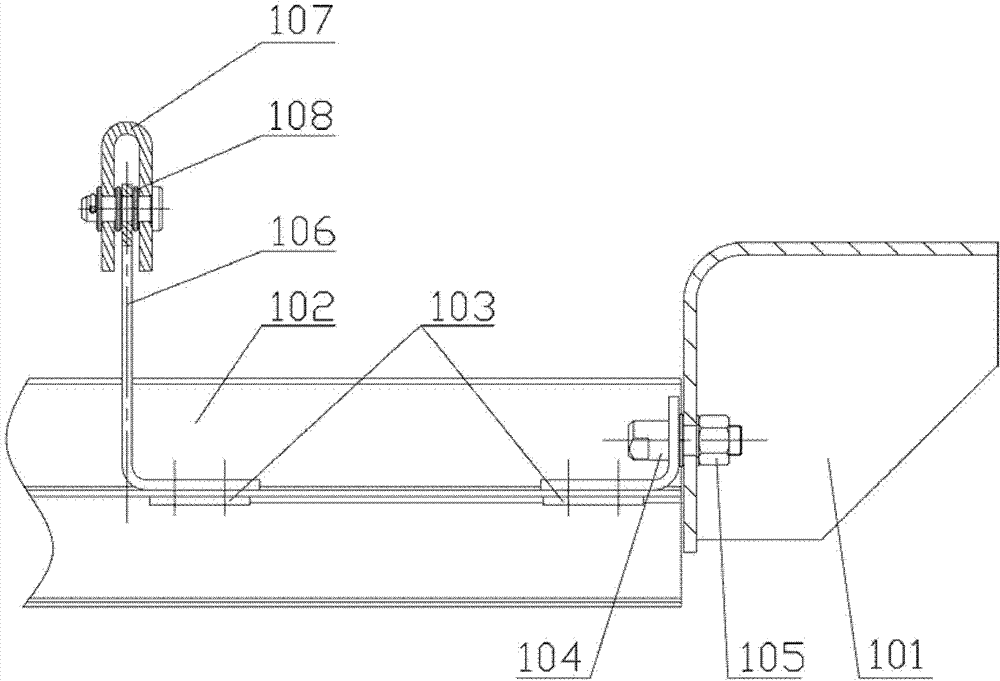

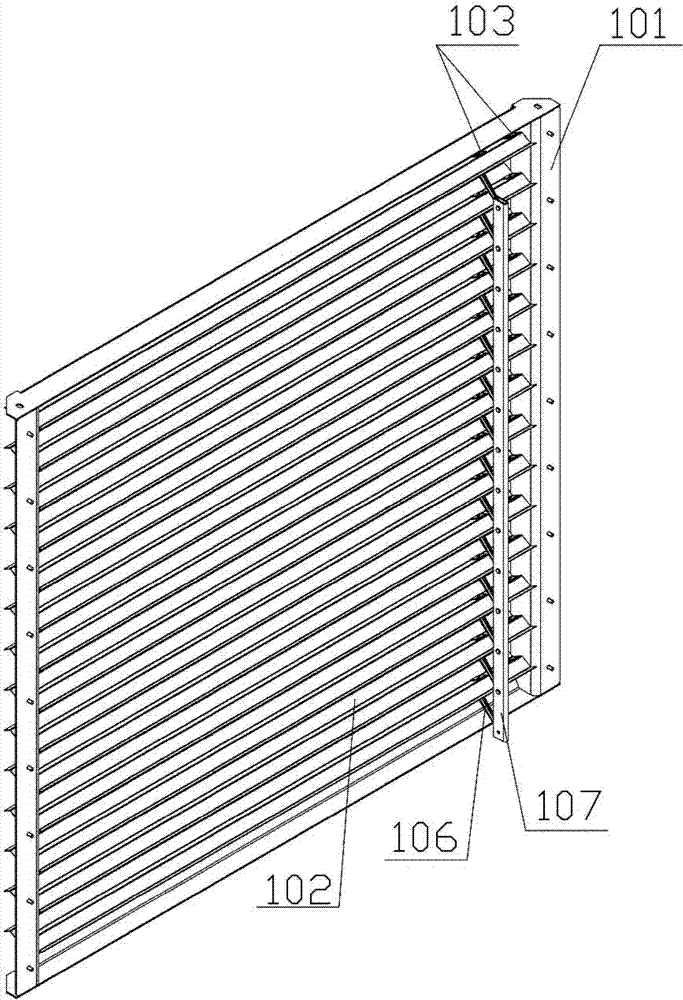

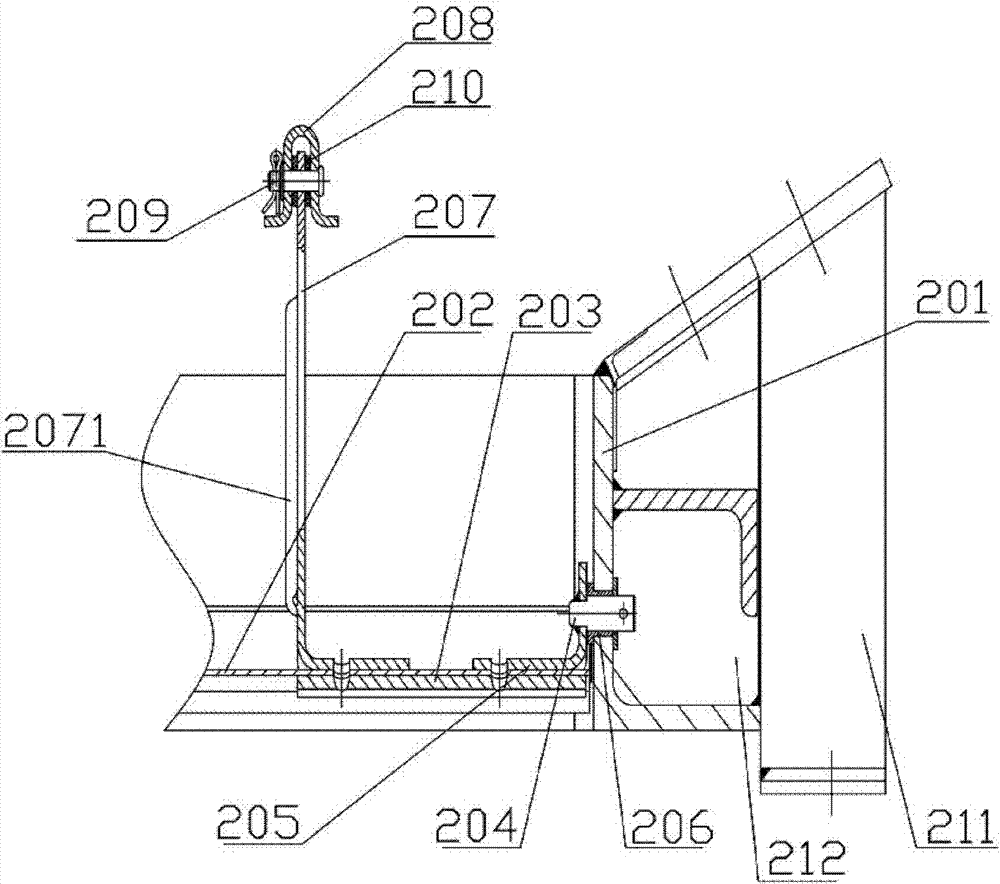

[0047] Such as Figure 4 , Figure 5 As shown, it is a structural schematic diagram of a vertical radiator louver device according to an embodiment of the present invention. Pull rod 208 , pin shaft 209 , nylon gasket 210 , leg 211 and reinforcing plate 212 .

[0048] Wherein, when the shutter device has a large volume, the frame 201 can be composed of at least two sub-frames, and each sub-frame is combined into an integral frame 201 through bolt connection or other detachable connection, so as to facilitate transportation and installation. The frame 201 in this embodiment is a composite frame of section steel, specifically a composite frame of angle steel. The frame of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com