Coil insertion method and coil insertion device

A coil insertion and coil technology, which is applied in the direction of prefabricated windings embedded in motors, can solve the problems of high end coils, additional parts, and unsuitable multi-phase coils, etc., and achieve the effects of reducing insertion resistance, saving coils, and high-efficiency stators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] For the purpose of shortening the height of the end coil protruding from the end face of the stator core, the curved part of the upper end of the coil that is inserted into the slot first is expanded. A space where the inside of the curved portion of the coil does not conflict with the outside of the curved portion of the upper end of the coil inserted into the slot later.

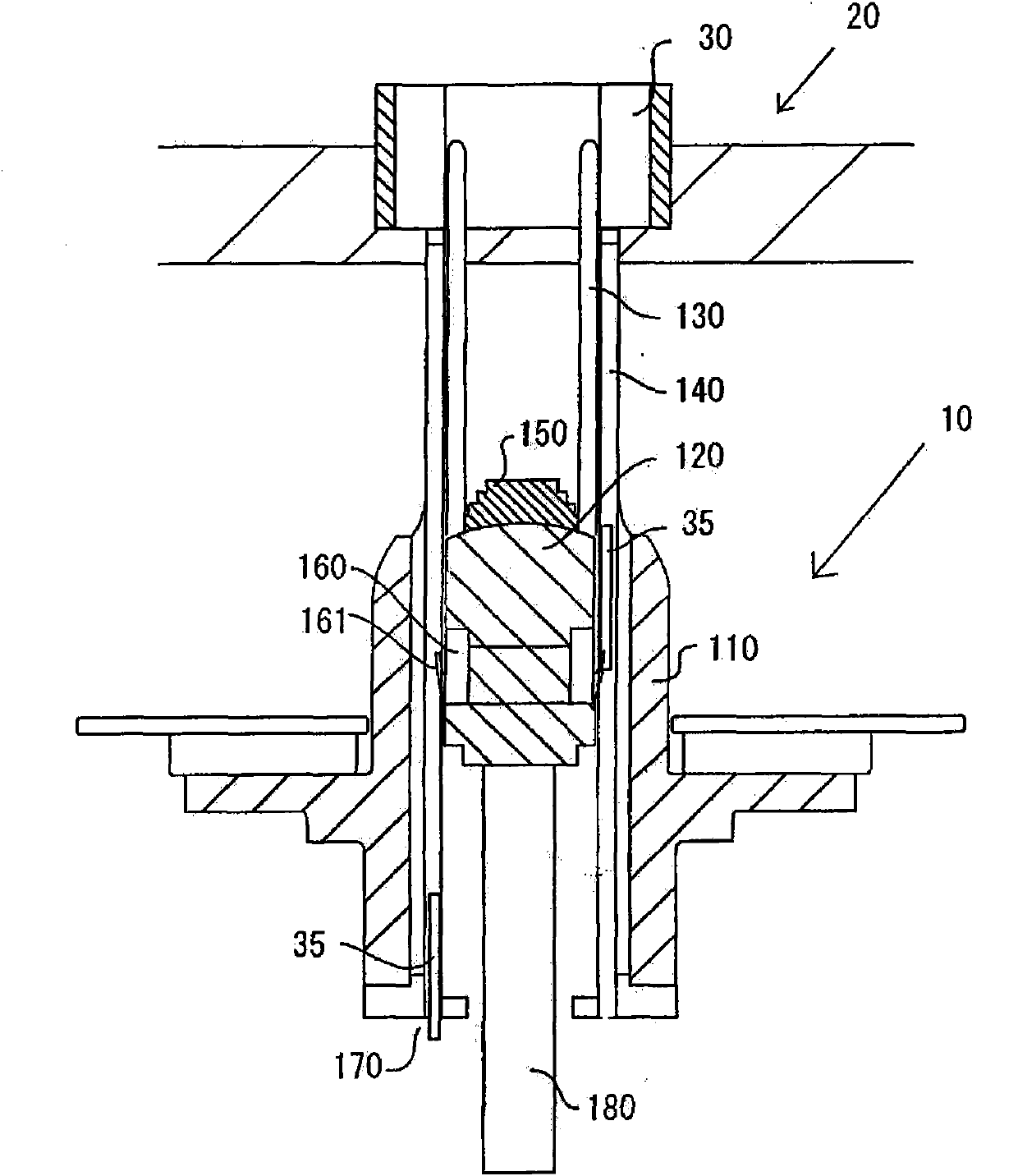

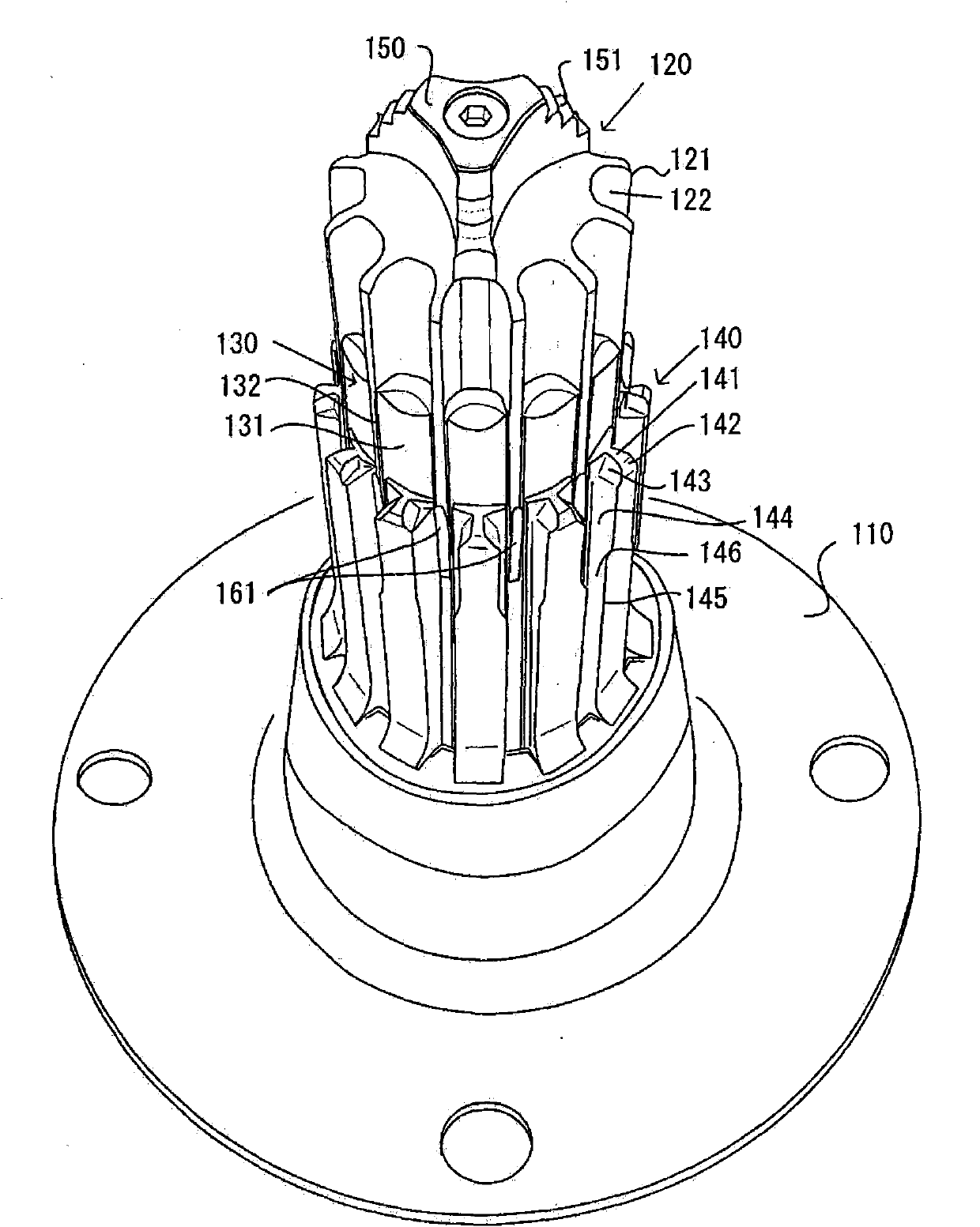

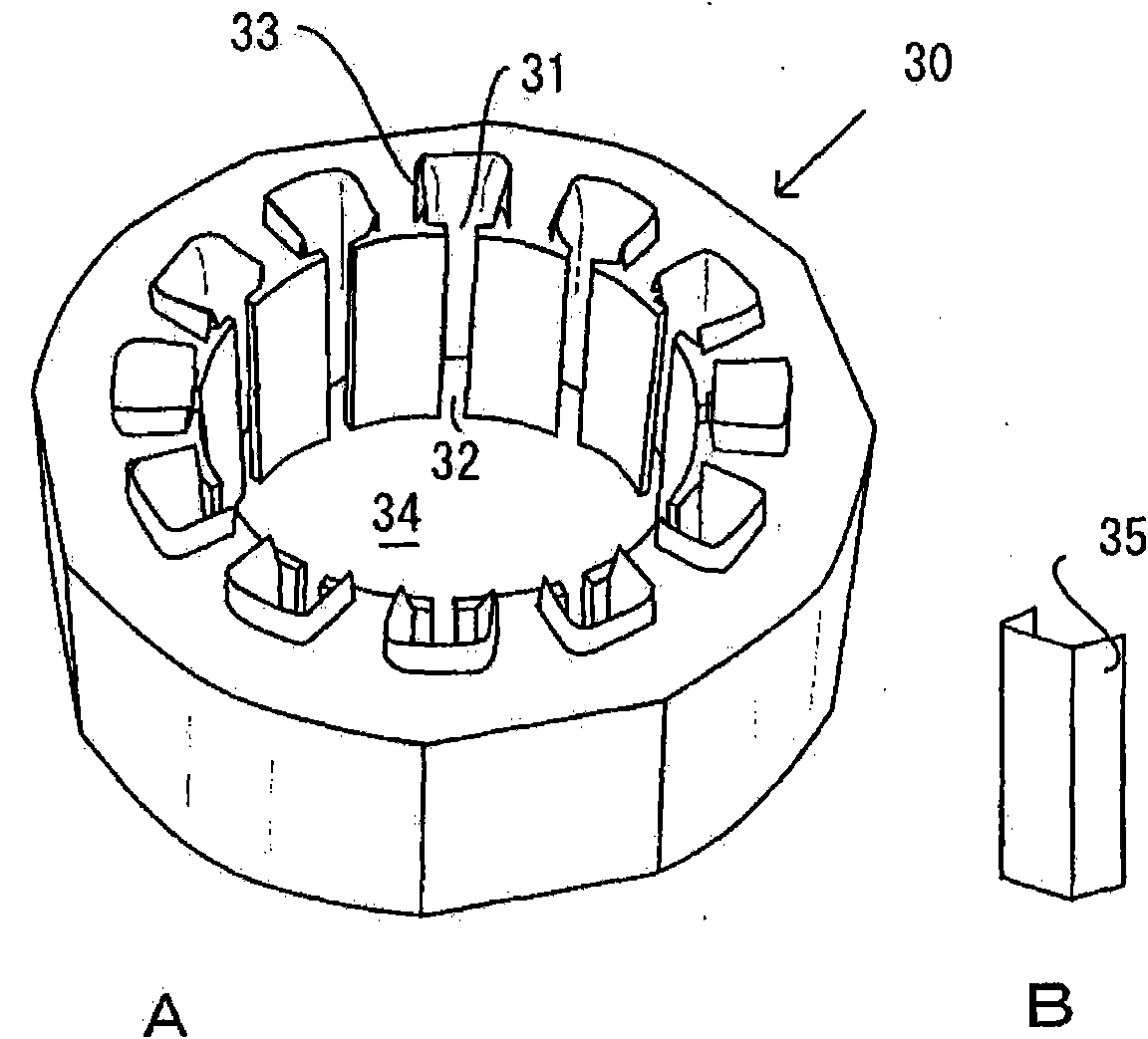

[0036] figure 1 It is a diagram illustrating the coil insertion mechanism 10 of the coil insertion device of the present invention through a longitudinal section, figure 2 It is a perspective view of the coil insertion mechanism 10 of the present invention, image 3 It is a perspective view of the stator core 30, and the perspective view of the coil insertion mechanism 10 shows the state in which the wire stripper 120 extended upwards for easy understanding of the whole. Figure 4 is a horizontal cross-sectional view of the coil insertion mechanism.

[0037] Such as image 3 As shown, a plurali...

Embodiment 2

[0073] This embodiment 2 replaces the coil expansion mechanism of embodiment 1, and its upper part is equipped with an inclined expansion mechanism for separating from the axis of the stator core while forming a curved surface at the part in contact with the coil curve above the stator core. The coil expansion mechanism of the guide part 250. The coil protruding from above the stator core is expanded along the expansion guide part 250 forming the above-mentioned curved surface, and the coil is expanded outward from the axial center of the stator core.

[0074] Figure 12 It is an explanatory diagram of the key parts of the stator core fixing mechanism with the coil expansion mechanism installed through the cross-section. The stator core 30 is sandwiched by a stator core fixing portion composed of the lower fixing portion 21 and the upper fixing portion 23 . The upper fixing part 23 is only at the upper position of the coil suspended above among the multi-phase coils, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com