Automatic fixing device for rolling fixture

A fixing device and rolling technology, applied in the field of auto parts production, can solve the problems of poor dimensional accuracy of rolled profiles, long time-consuming rolling tooling, low production efficiency, etc., to achieve stable and reliable pressing force, reduce labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

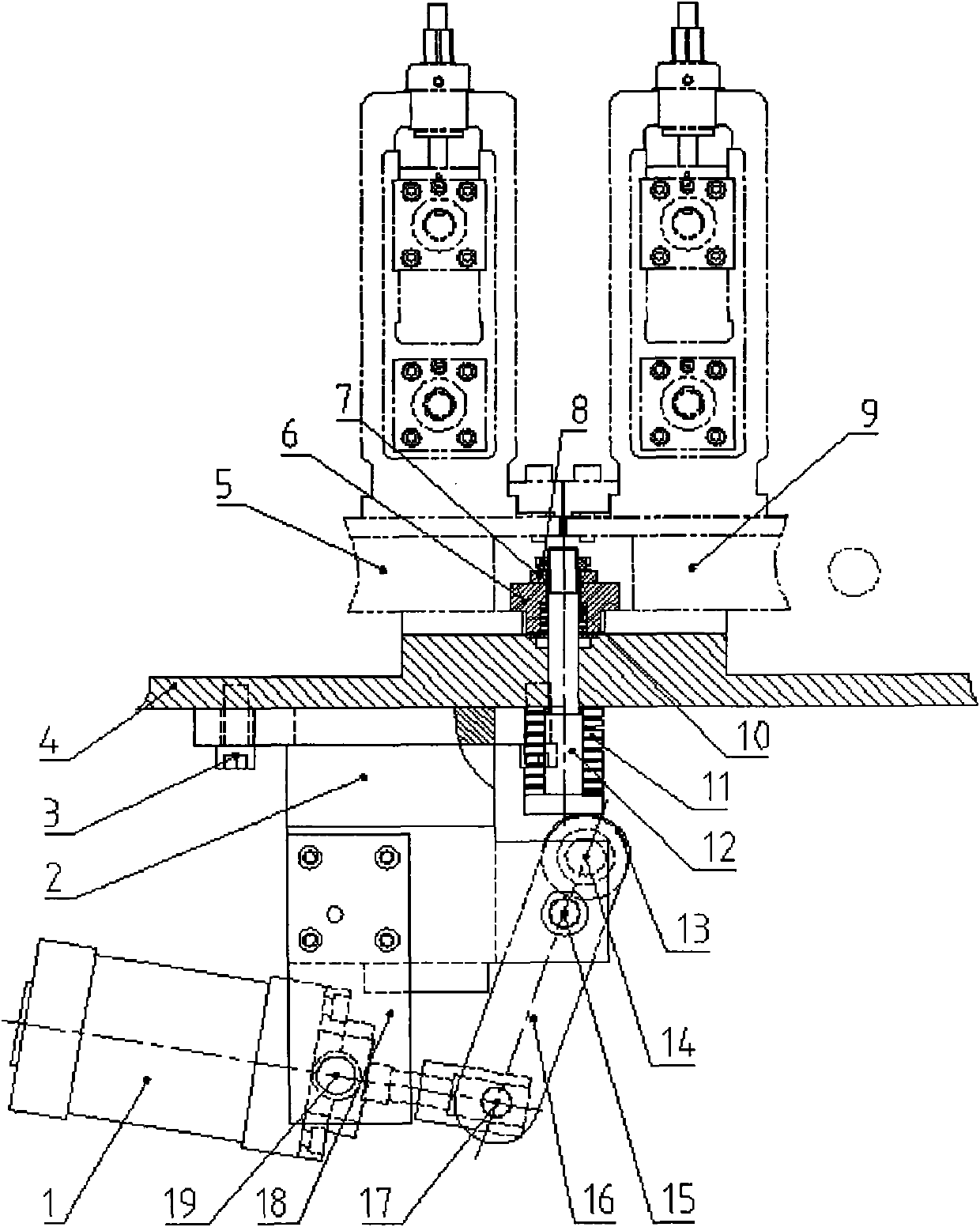

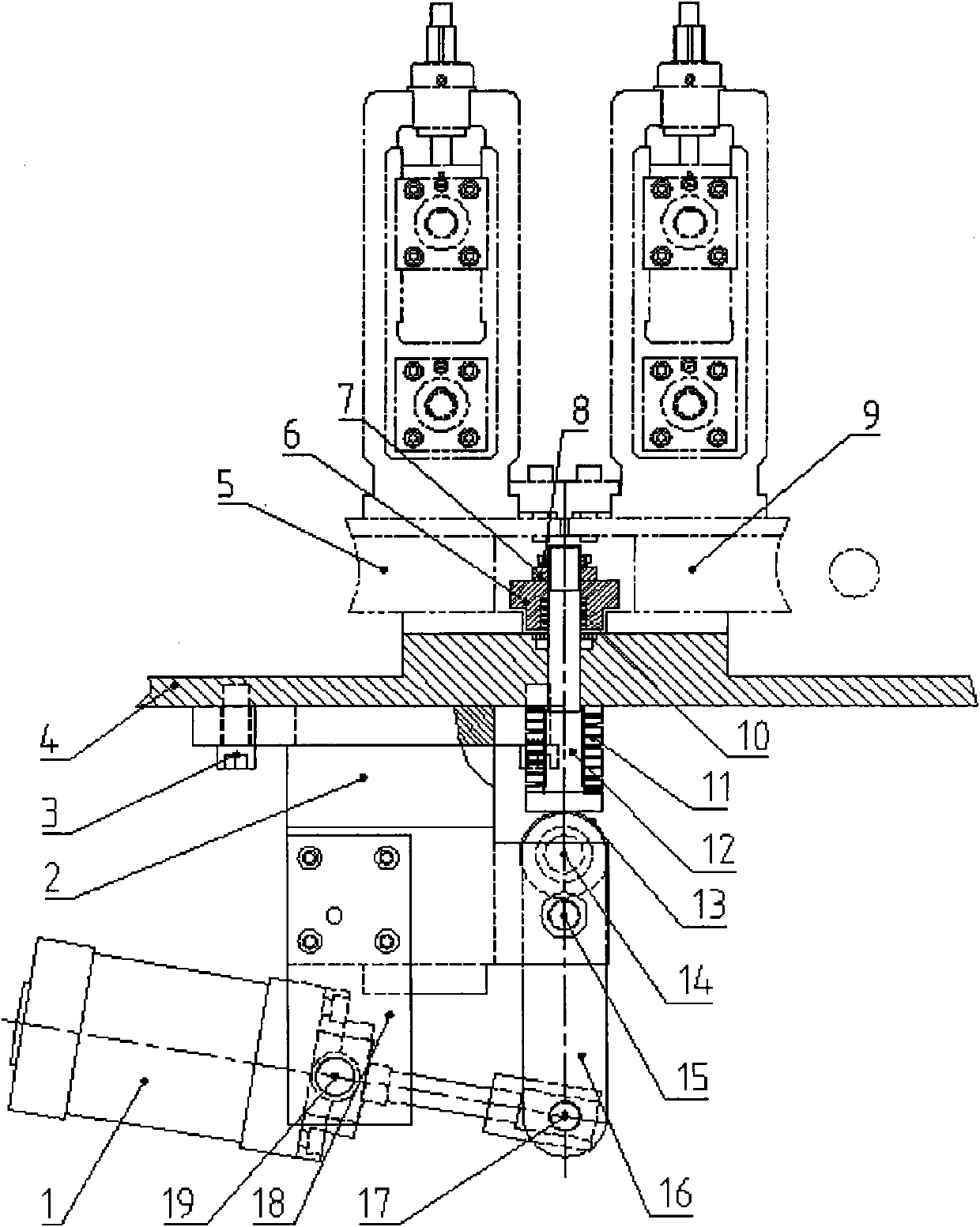

[0011] The double-dot chain line in the figure represents a part of two sets of rolling tooling (5, 9). The first rolling tooling 5 and the second rolling tooling 9 are respectively placed on the rolling work platform 4, and the two bases thereof are simultaneously pressed by the pressing block 6. The compression block 6 and the upper cushion block 7 are respectively sleeved on the pull rod 12, and the upper part of the cushion block 7 is blocked by a lock nut 8. The center of the compression block 6 is machined with a stepped through hole, and a return spring is installed in the stepped through hole. 10. The lower end of the tie rod 12 has a flange with threads on the upper part, the tie rod 12 passes through the work platform 4, and a compression spring 11 is sleeved below, and the lower surface of the flange at the lower end of the tie rod is supported by the roller 13. The roller 13 is installed at one end of the rotating arm 16 through the first rotating shaft 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com