Transparent printing film and manufacturing method thereof

A manufacturing method and inkjet technology, applied in the direction of special decorative structures, decorative arts, layered products, etc., can solve the problems of being easily disturbed by other scenes, affecting the transparency of transparent inkjet film, affecting the performance of advertising pictures, etc., to meet the transparent Light and perspective effects, prevent scene interference, and prevent strong light interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

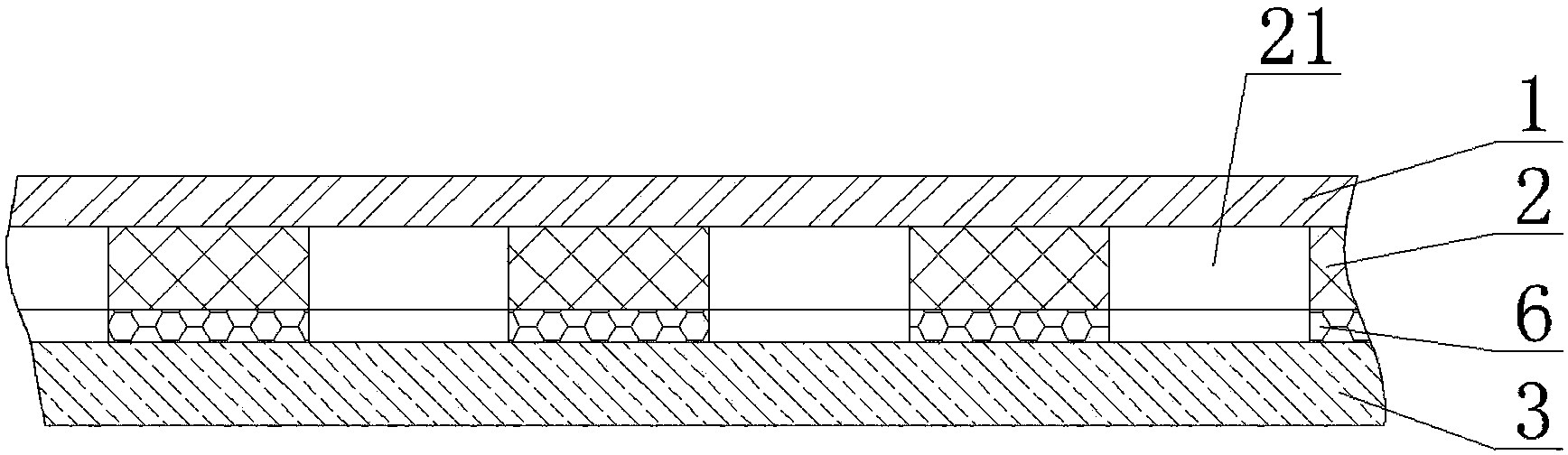

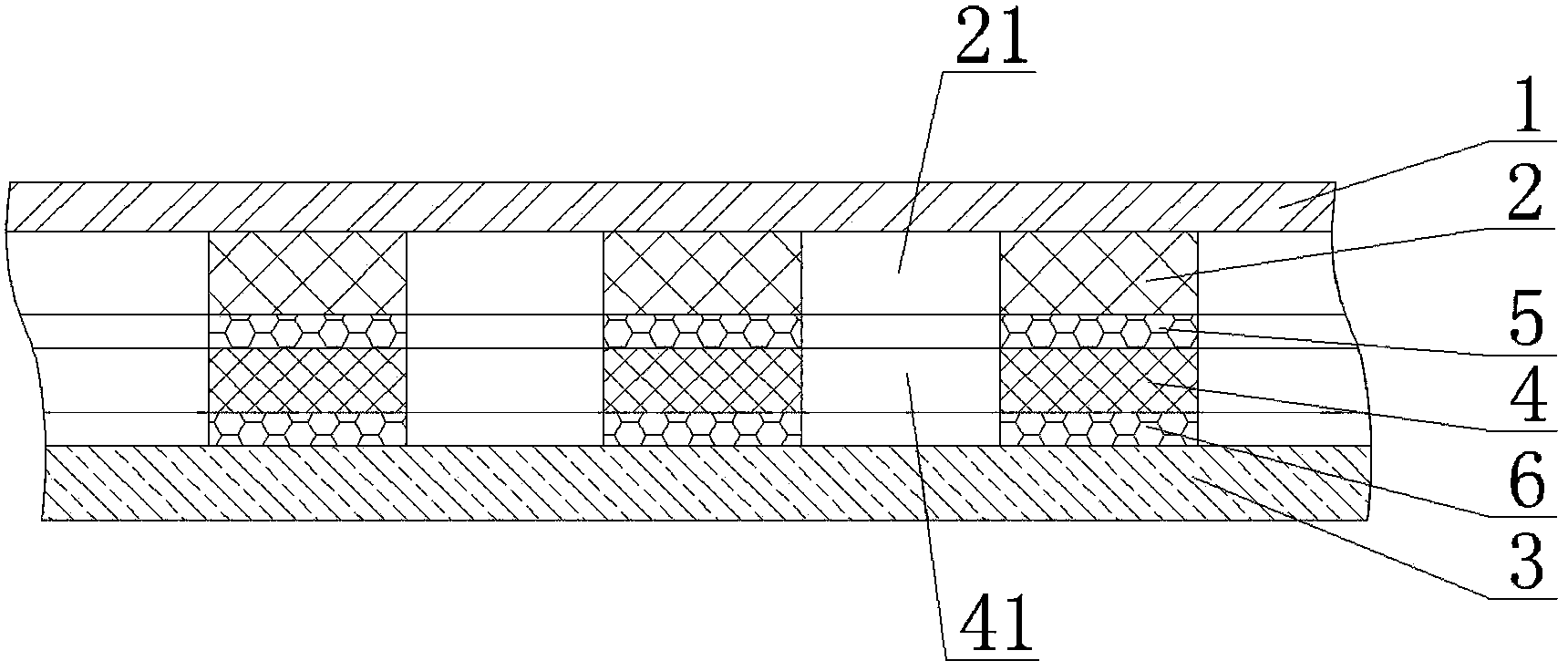

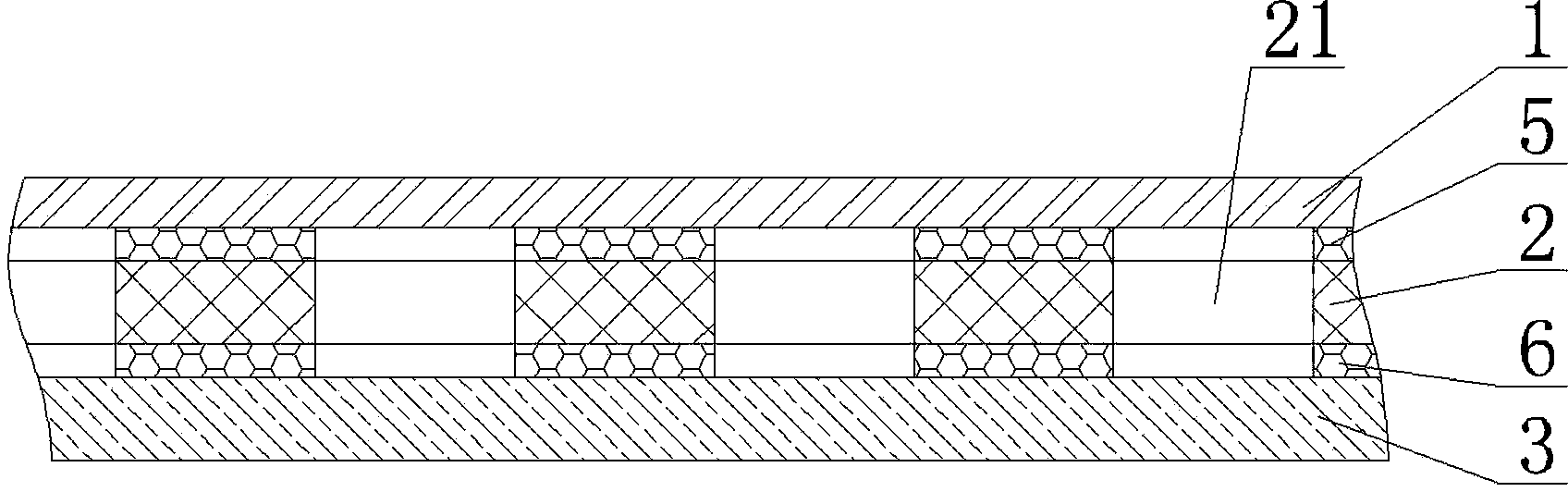

[0025] Such as Figure 1-Figure 5 As shown, the transparent inkjet film of the present invention includes transparent inkjet layer 1 and backing paper 3, in order to clearly show the pictures sprayed on the transparent inkjet layer 1, and enhance the contrast of the pictures on the transparent inkjet layer 1 , so that the display of the picture is clear and the visual effect is good. A white color-developing film 2 is arranged between the transparent spray-painting layer 1 and the base paper 3, and a plurality of through holes 21 are densely distributed on the white color-developing film 2 . The through hole 21 may be circular or square or rhombus or triangular or other shapes. Wherein, the backing paper 3 is release paper or coated paper or release paper or PET film. Moreover, a self-adhesive layer 6 is coated on the bonding surface of the white color-developing film 2 and the backing paper 3, so that the white color-developing film 2 can be pasted on the backing paper 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com